Rubbish can cleaning system

A cleaning system and trash can technology, applied in the field of trash can cleaning systems, can solve the problems of scratches, uneven spacing, cleaning brush bristles easy to wear the outer wall of the trash can, etc., and achieve the effect of reducing the contact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

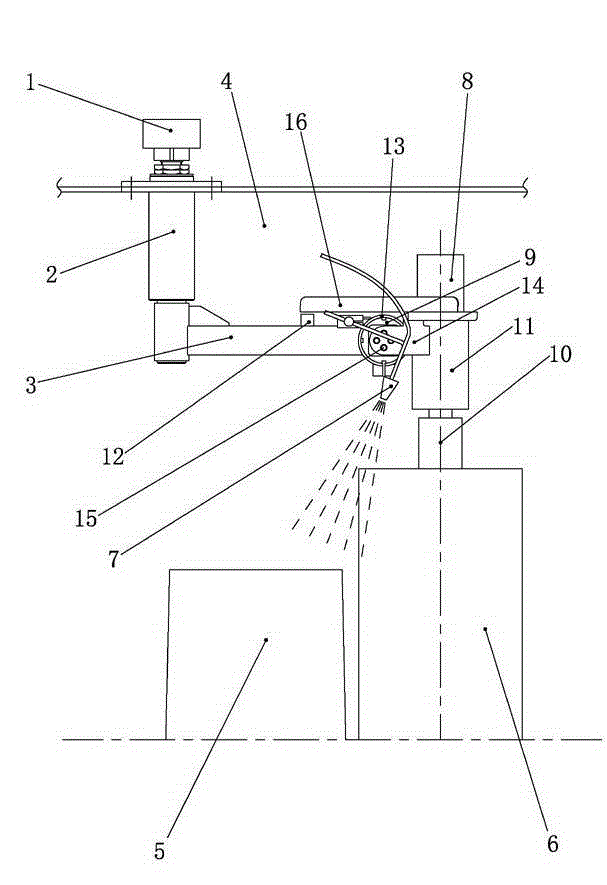

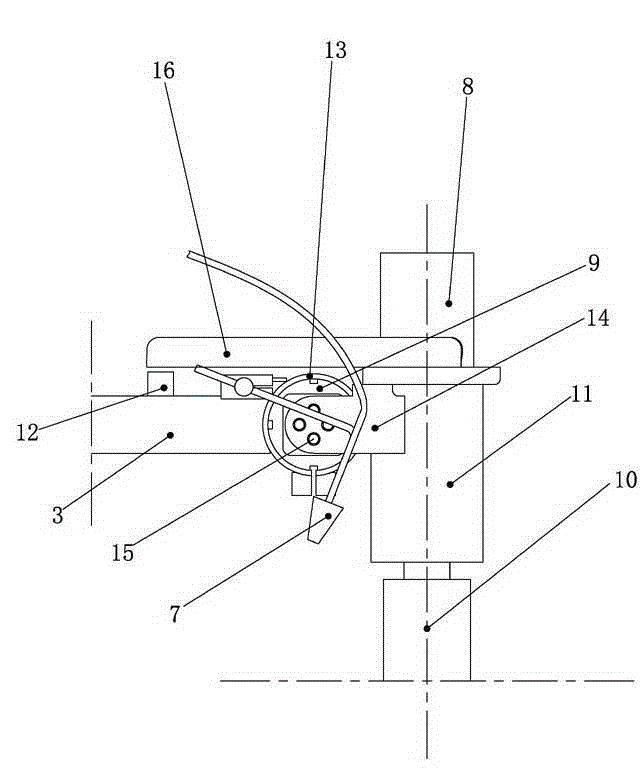

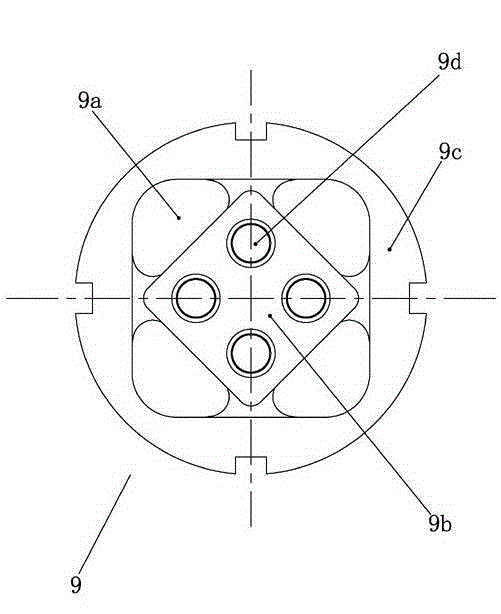

[0017] Such as Figure 1-4 As shown, a garbage can cleaning system includes a driving source 1 fixedly installed on the washing chamber 4, a power main shaft 2 rotatably installed vertically on the output end of the driving source 1, and a rotating arm vertically fixed on the bottom end of the power main shaft 2 3. The scrubbing assembly installed at the end of the rotating arm 3 and the spray mechanism 7 installed on the rotating arm 3; the scrubbing assembly includes a driving motor 8, a fixed base 11, a rotating shaft 10, and a cleaning brush in contact with the outer wall of the trash can 5 6. The axis of the rotating shaft 10 is perpendicular to the extension of the rotating arm 3. The fixed base 11 is installed at the end of the rotating arm 3. The cleaning brush 6 is mounted on the lower section of the rotating shaft 10, and the upper section of the rotating shaft 10 can rotatably pass through the fixed base. 11 is fixedly connected with the output end of the driving mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com