A smoke and dust circulation filter device

A technology of circulating filtration and dust, which is applied in the direction of combined devices, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of large water consumption, channel blockage, etc., and achieve the effects of saving costs, improving effects, and ensuring the recycling of water bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

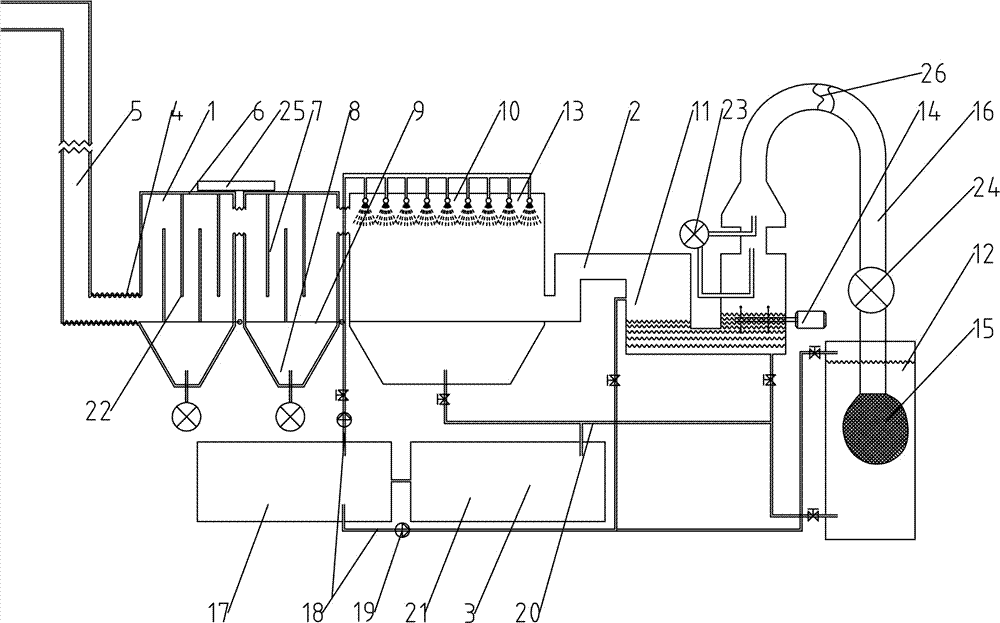

[0025] like figure 1 As shown, a smoke and dust circulation filter device includes a dry dust removal device 1, the two ends of the dry dust removal device 1 are respectively connected to the smoke and dust inlet 5 and the water bath dust removal device 2 through the bellows 4, and the water bath dust removal device 2 is composed of a water circulation system 3 water supply, drainage;

[0026] The dry dust removal device 1 includes a body 6, a secondary gas phase labyrinth is arranged above the body 6, the gas phase labyrinths 7 are connected by bellows 4, and a conveying device 8 is provided at the bottom of the body 6, and the conveying device 8 is Screw conveyor; the gas phase labyrinth 7 and the conveying device 8 are separated by a movable partition 9;

[0027] The water bath dedusting device 2 includes a spray area 10, a first pool area 11 and a second pool area 12, and the spray area 10, the first pool area 11 and the second pool area 12 are sequentially sealed and con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap