Opposed Piston Engine Layout in Heavy Trucks

A technology of opposed pistons and engines, which is applied in the direction of machines/engines, power plants, vehicle components, etc., and can solve problems such as increasing engine power loss and limiting engine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

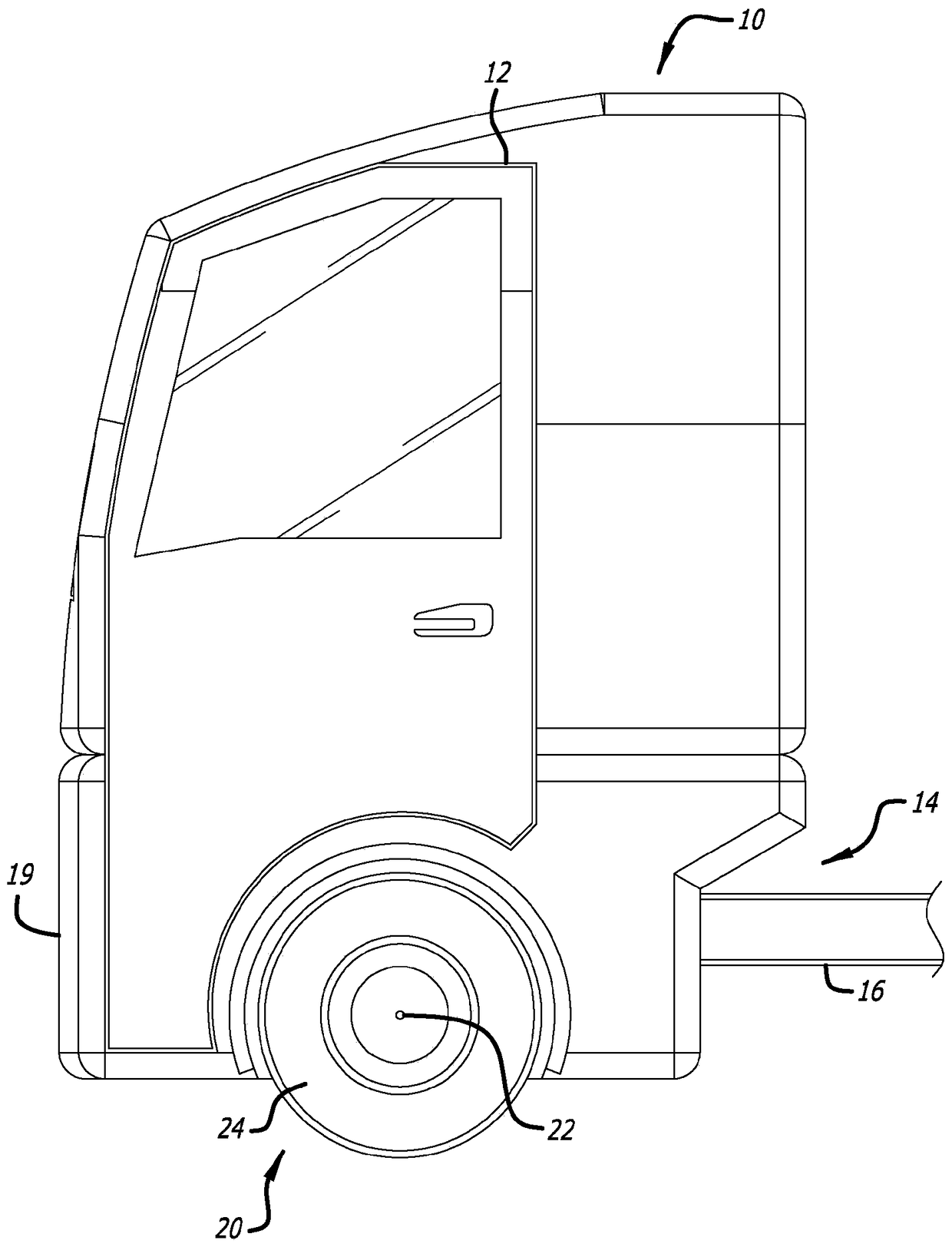

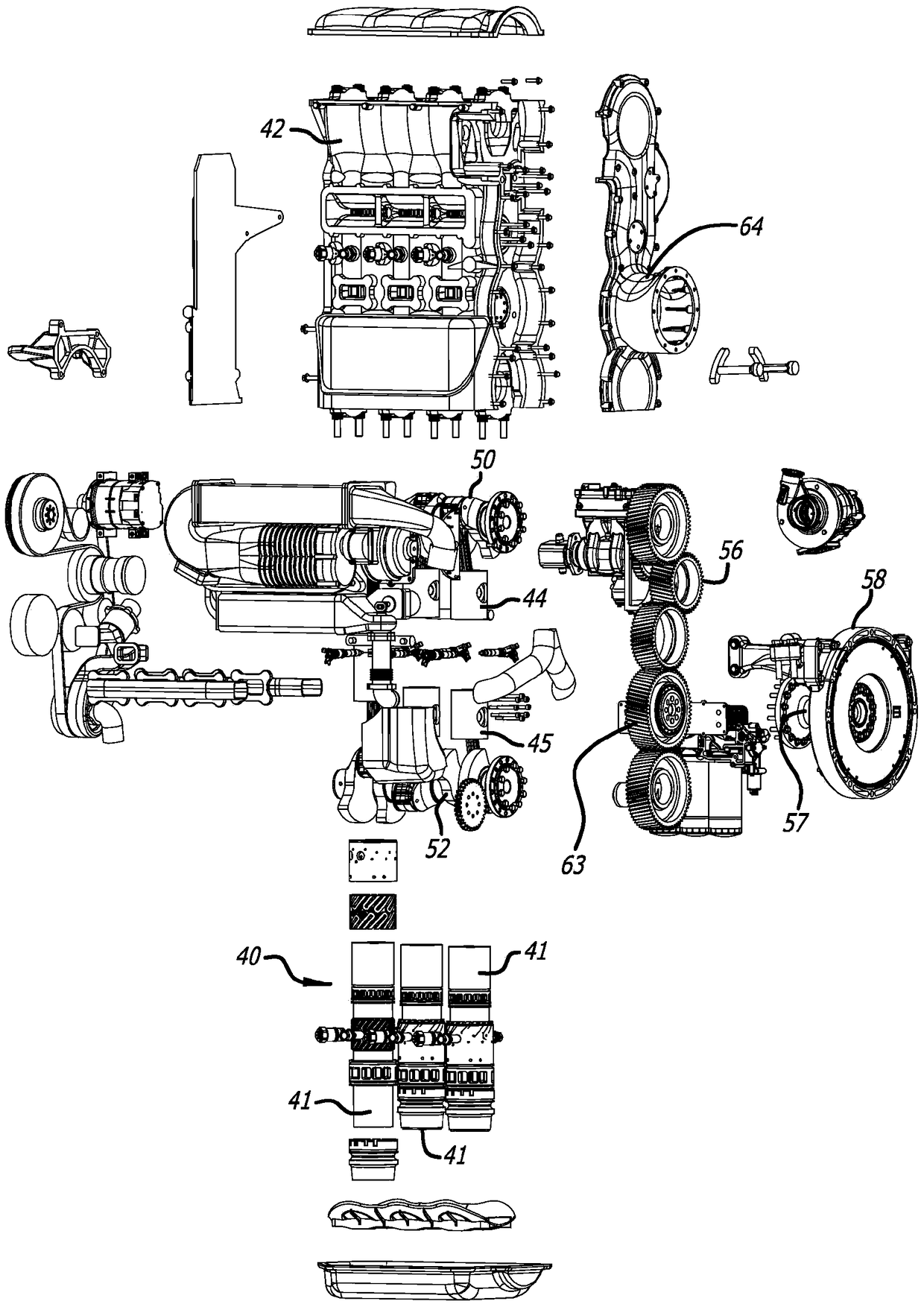

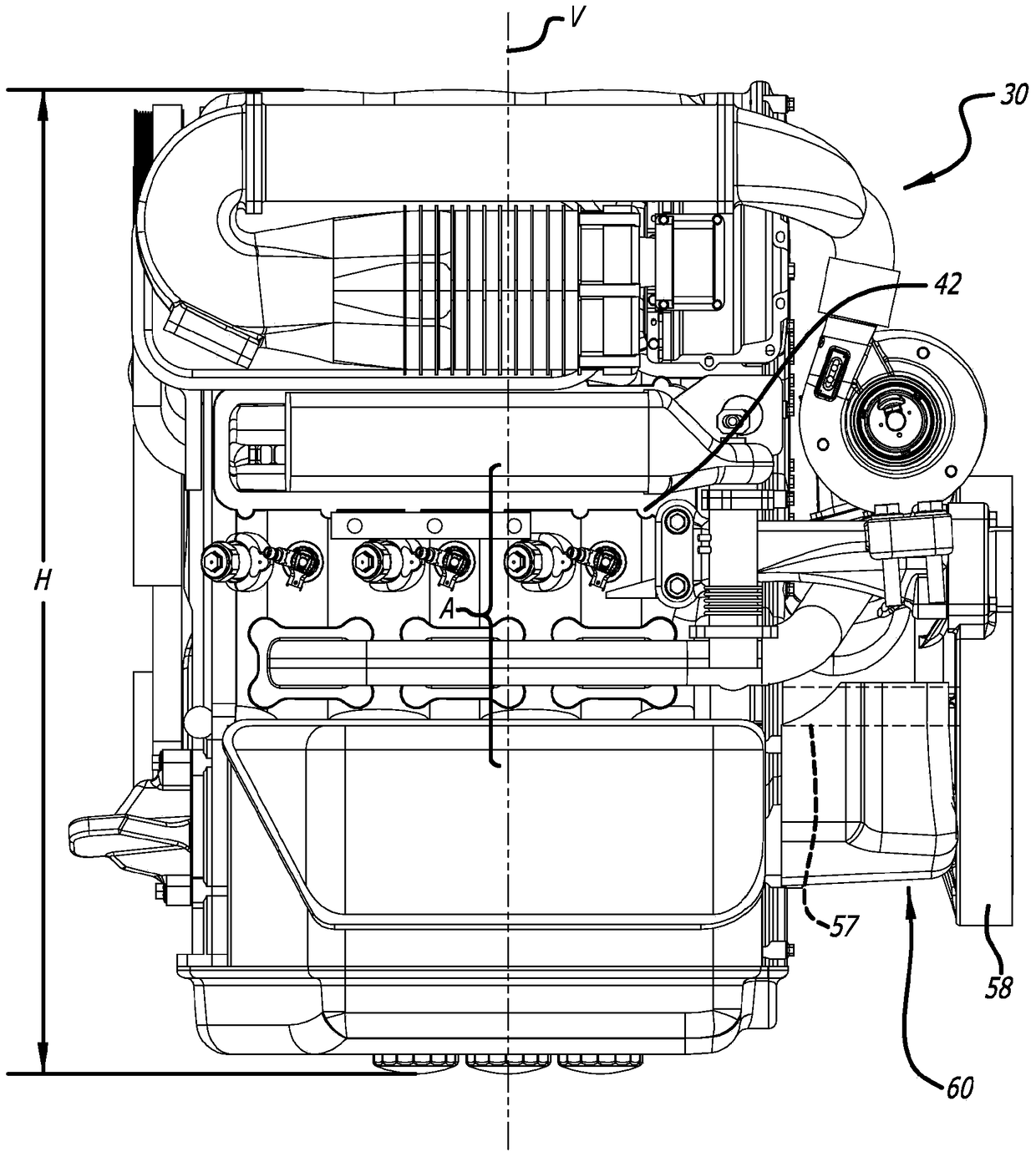

[0022] This description is directed to the layout of an opposed-piston engine in a heavy-duty truck that includes a bed and front wheel assembly, the bed having two spaced apart frame rails extending in the longitudinal direction of the truck between the front and rear ends, the front wheel The assembly has an axle attached to the frame rail. The opposed-piston engine is supported on frame rails and positioned between the front end and the axle. In one embodiment, an opposed-piston engine includes a cylinder assembly having a longitudinal axis disposed between frame rails and oriented perpendicular to a longitudinal direction. In another embodiment, the opposed piston engine includes a bank of cylinders disposed in the space between the frame rails and extending longitudinally of the truck.

[0023] refer to figure 1 with Figure 5 The front (front) portion of the heavy truck 10 includes a cab 12 having a base 14 with a frame beam 16 extending in the longitudinal direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com