Helical hybrid stent

A helical, main stent technology, applied in the field of stents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

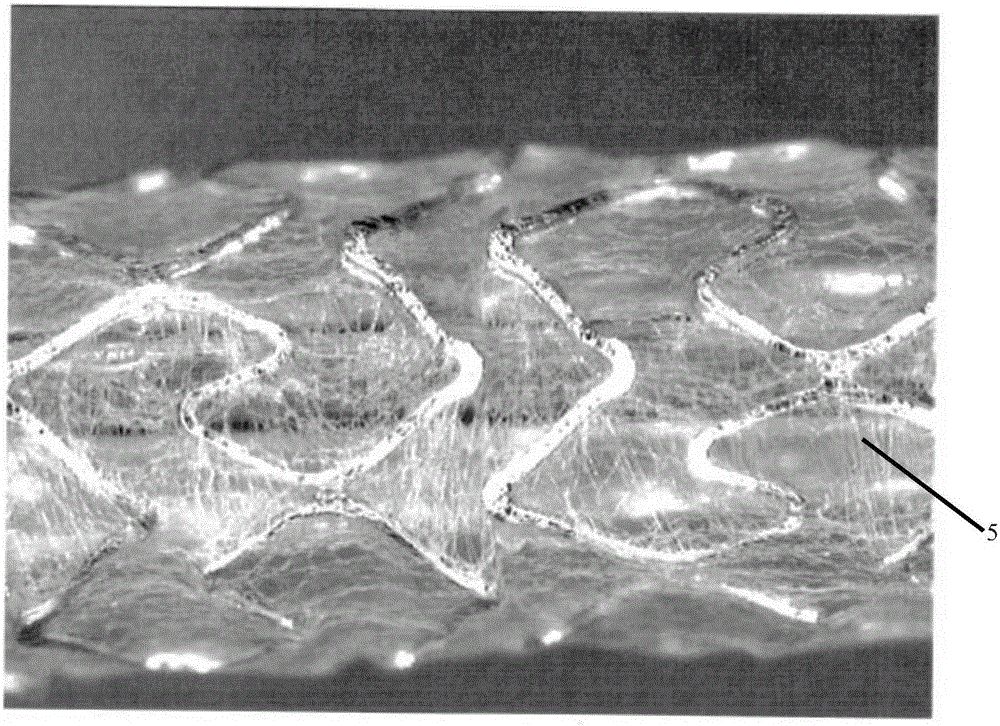

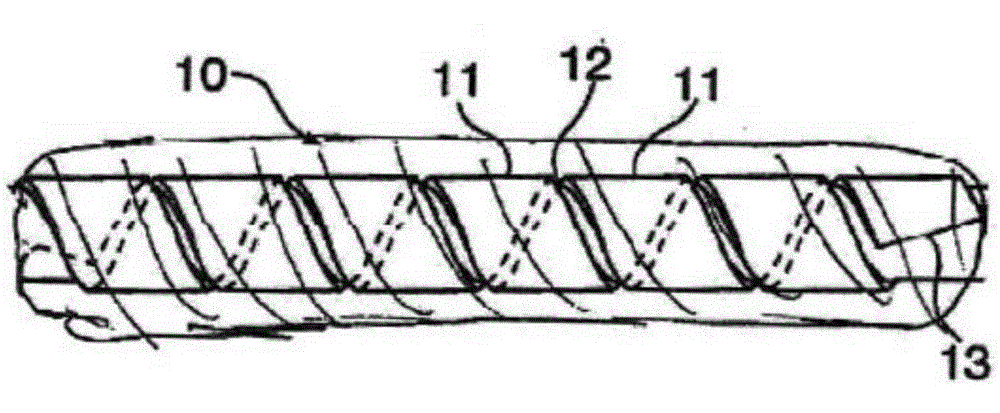

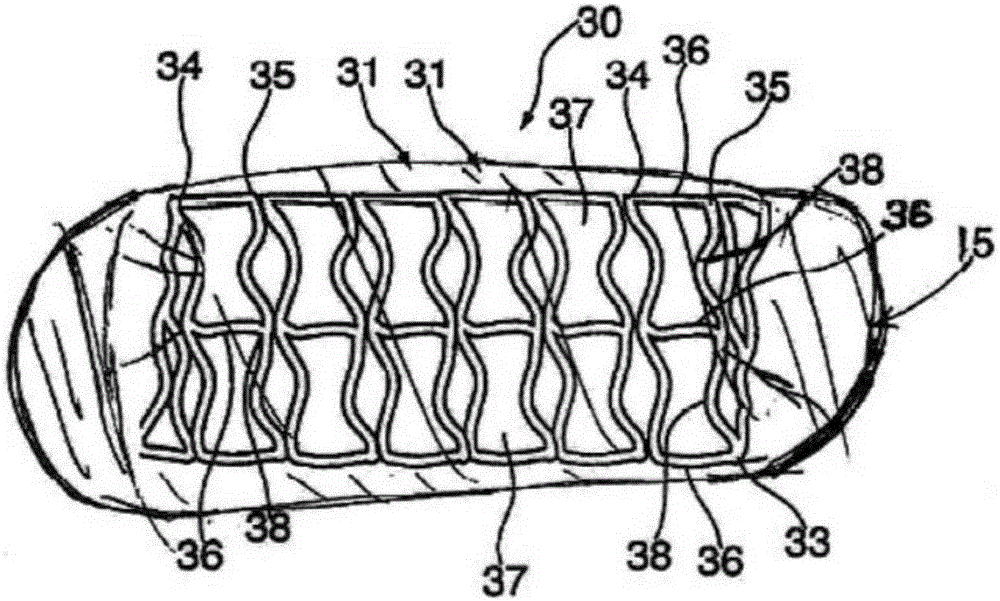

[0035] The present invention provides a new class of endoluminal prosthetic devices defined as helical hybrid stents. In particular, the stents of the present invention comprise a main stent component in the form of a helical tubular structure. The main stent component may be held in its coiled position by a second component that secures the helical coil into the tubular structure. The second component may be one or more of various means of securing the main stent component in tubular form. The second component may for example be a weld, an interlock and / or a polymer. In one embodiment, the second component comprises a polymer or polymer fibers wrapped around or embedded within the coiled main stent component. The elastic range of the polymer fiber layer must be sufficient to allow expansion and maximum bending of the stent during and after implantation without reaching the elastic limit.

[0036] The stents of the invention may be balloon expandable or self-expanding, or f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com