Motor and motor case thereof

A technology for electric motors and casings, which is applied in the direction of electric components, casings/covers/supports, electrical components, etc., and can solve problems such as waste of materials and complicated manufacturing process of motor casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

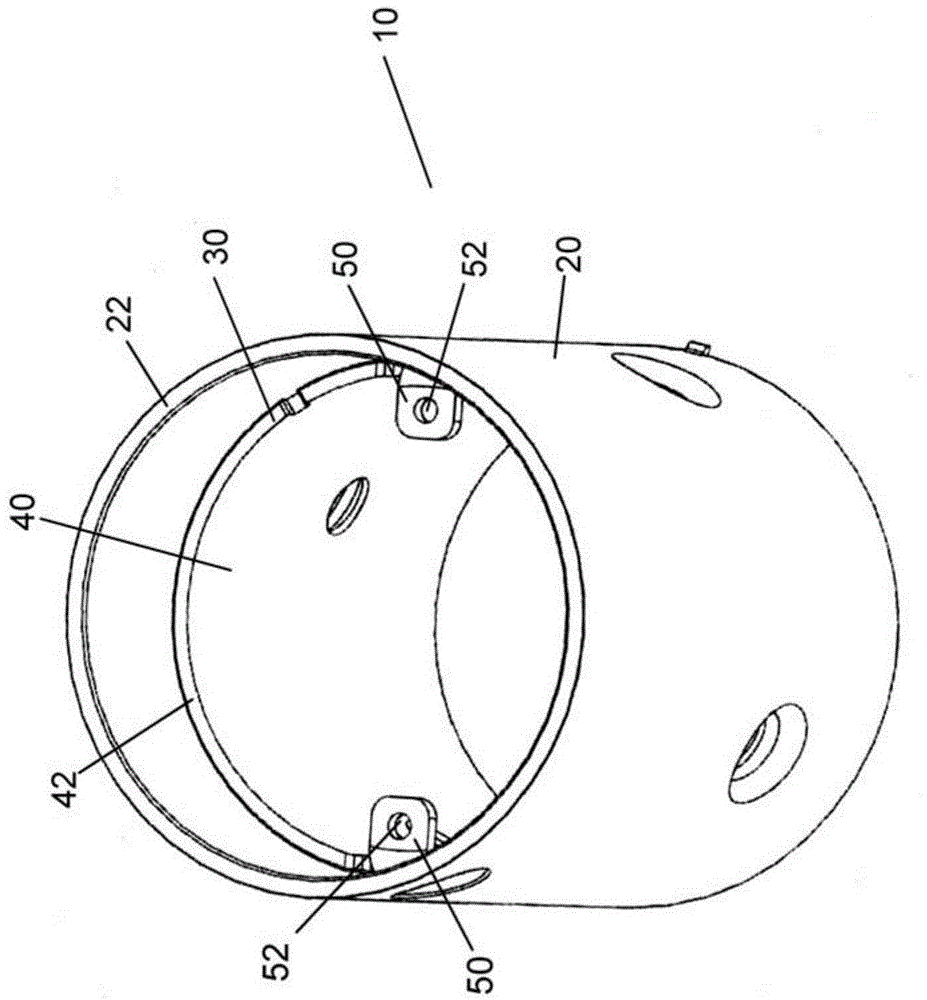

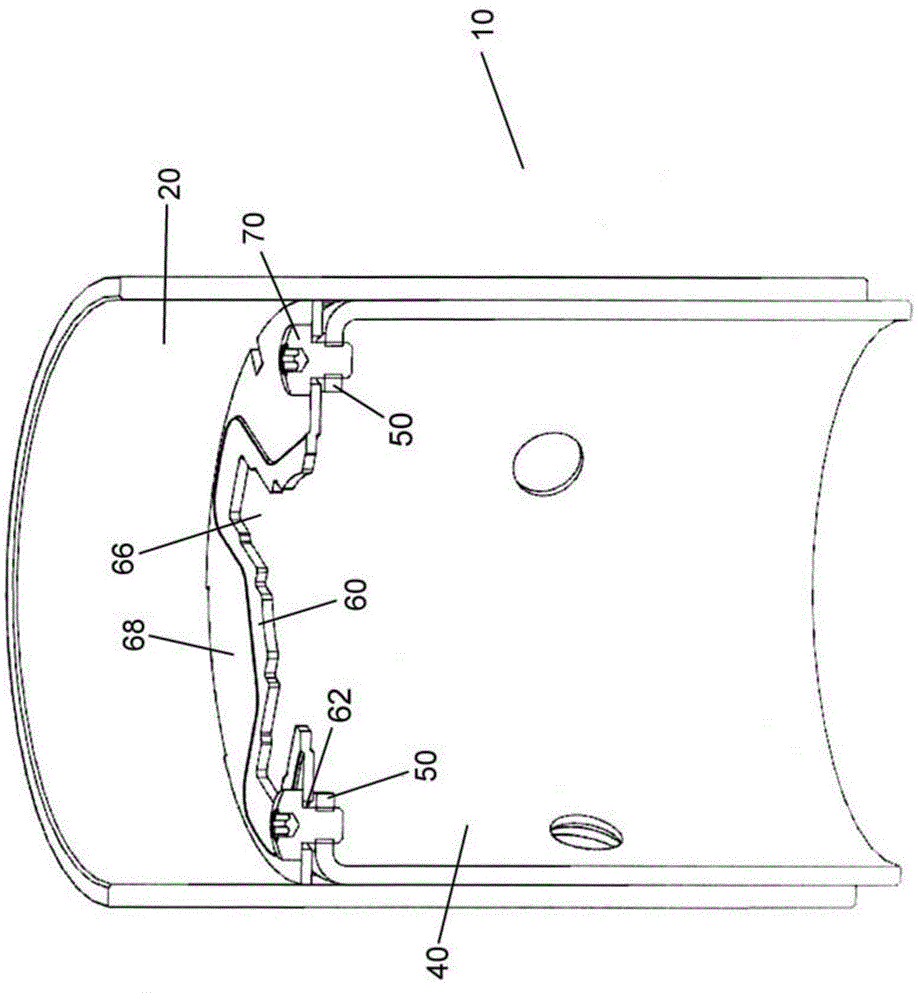

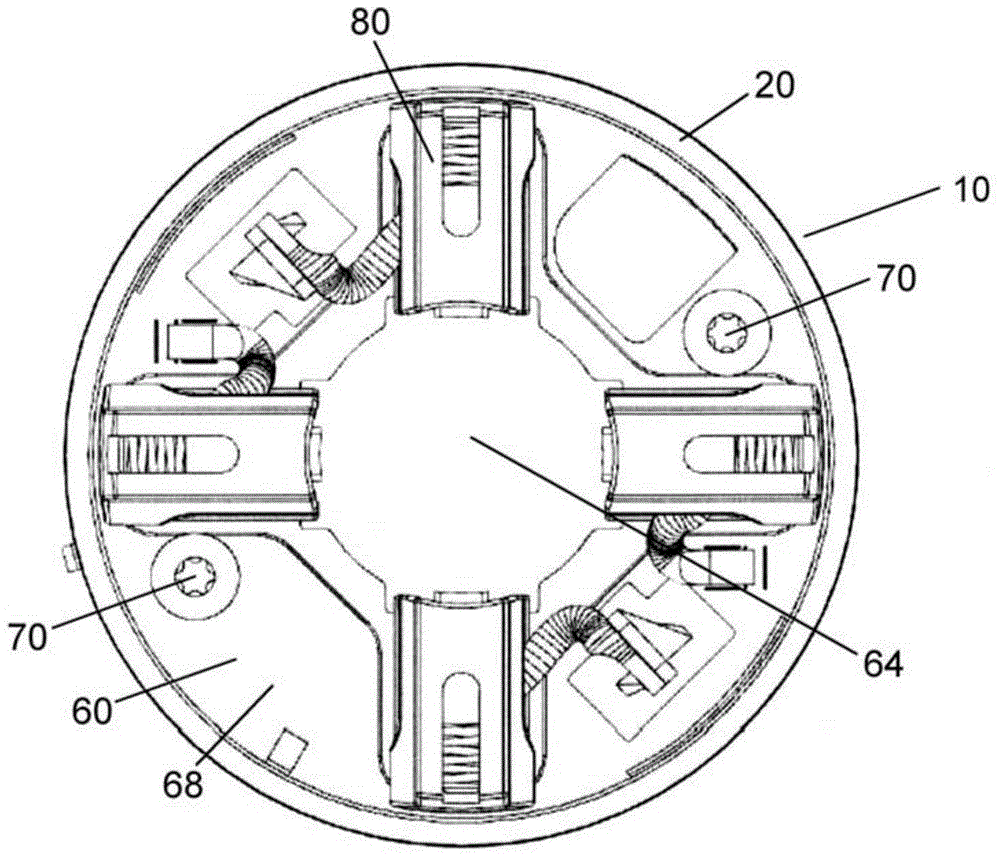

[0023] Refer below Figure 1-4 Alternative embodiments of the present invention are described. In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

[0024] The electric motor according to the present invention is applicable to various electric motors including carbon brushes, for example, electric motors for vehicle engines.

[0025] According to the present invention, the motor includes a motor double-layer housing 10 and various components (not shown in the figure) accommodated therein, including but not limited to functions such as magnetic pole shoes, field windings, armatures, carbon brushes, and motor output shafts. Sexual parts and accessories such as bearings.

[0026] Such as figure 1 As shown, the double-layer housing 10 of the motor according to the present invention is cylindrical and assembled from two separate parts, including a first cylinder 20 and a second cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com