Ground clamping mechanism for high-altitude grounding device

A technology of high-altitude grounding device and clamping arm, which is applied in the direction of multi-core cable end parts, etc., which can solve the problems of complex structure of three-grip chuck, low grasping reliability, and the need to configure additional trucks for air source, etc., to achieve grounding The effect of simple and reliable clamping and releasing action, simple structure and high efficiency of grounding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

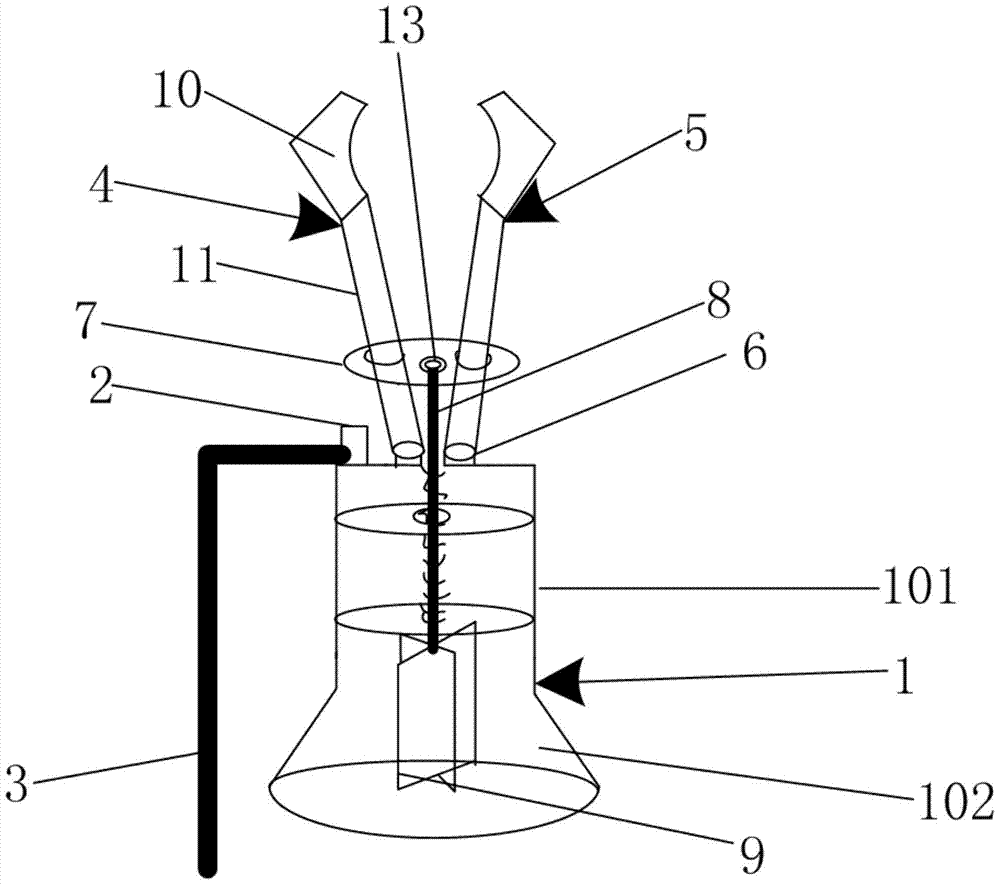

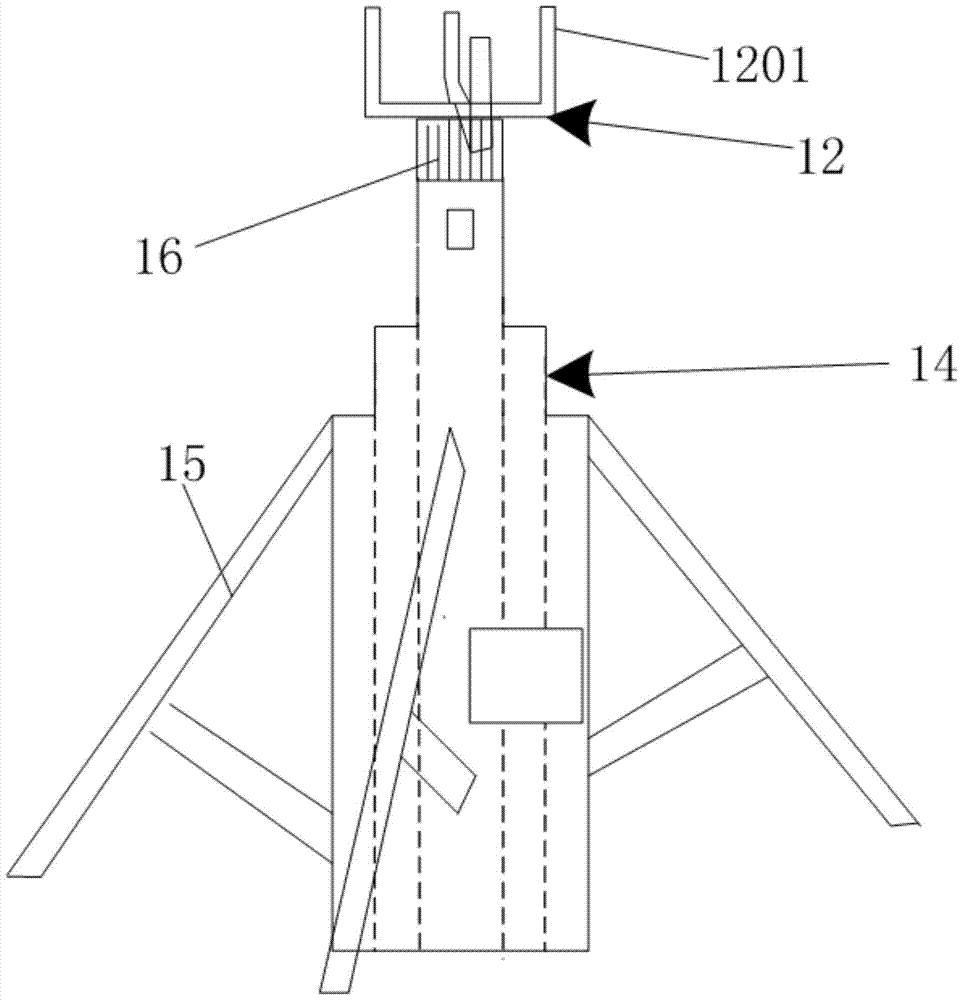

[0022] see Figure 1 ~ Figure 2 , the ground clamping mechanism for the high-altitude grounding device of the present invention includes a base 1, the top of the base 1 is provided with a terminal pile head 2 and a clamp arm, and the ground wire 3 is connected to the terminal pile head 2; There are two clamp arms, respectively the first clamp arm 4 and the second clamp arm 5; the first clamp arm 4 and the second clamp arm 5 are hinged to the top end of the base 1 through a hinge portion 6 ; The first clamp arm 4 and the second clamp arm 5 are sheathed with a movable chuck 7, and when the movable chuck 7 moves up, the distance between the two clamp arms is reduced to realize the clamping action, and the moving When the chuck 7 moves down, the distance between the two clamp arms increases to realize the release action;

[0023] The inside of the base 1 is provided with a threaded hole, and a rotating shaft 8 passes through the threaded hole, and the rotating shaft 8 is threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com