A vehicle-mounted wheel set flaw detection method and system

A vehicle-mounted and wheel-set technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of long construction period, low efficiency, and heavy workload of staff, and achieve no need for line construction, simple manual operation, and detection fast and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

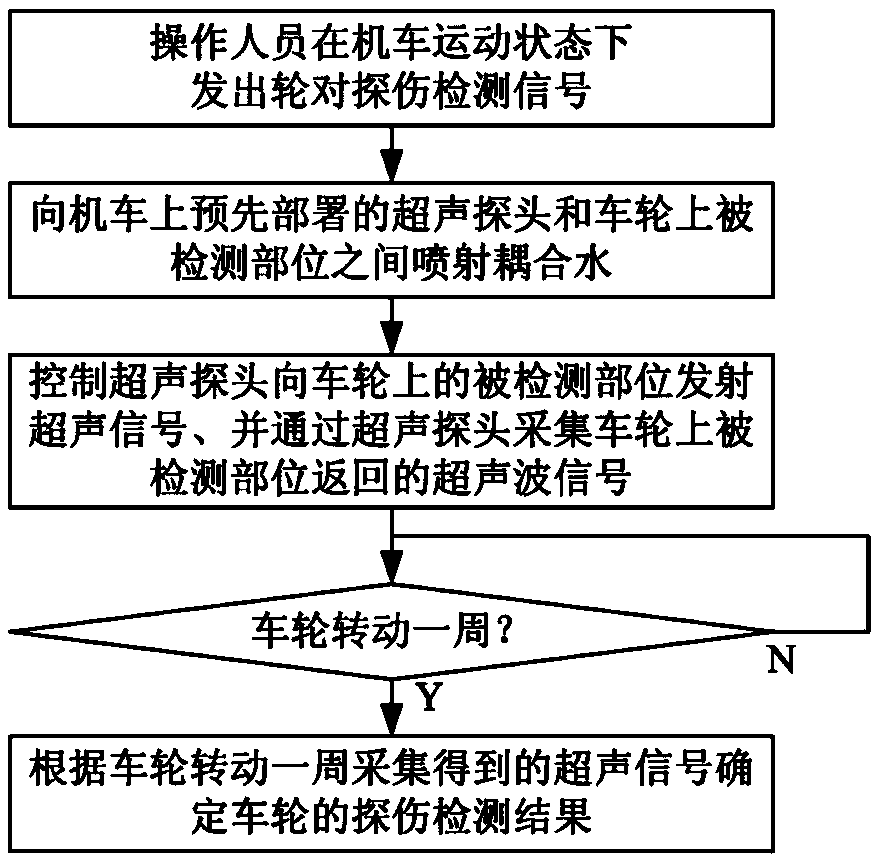

[0037] Such as figure 1 As shown, the steps of the vehicle-mounted wheel set flaw detection method of the present embodiment include:

[0038] 1) The operator sends a wheel set flaw detection signal while the locomotive is in motion;

[0039] 2) After receiving the wheel set flaw detection signal, spray coupling water between the pre-deployed ultrasonic probe on the locomotive and the detected part on the wheel, so that ultrasonic coupling is formed between the ultrasonic probe and the detected part on the wheel, and at the same time control the ultrasonic The probe emits an ultrasonic signal to the detected part on the wheel, and collects the ultrasonic signal returned by the detected part on the wheel through the ultrasonic probe, and determines the flaw detection result of the wheel according to the ultrasonic signal collected by the wheel for one rotation.

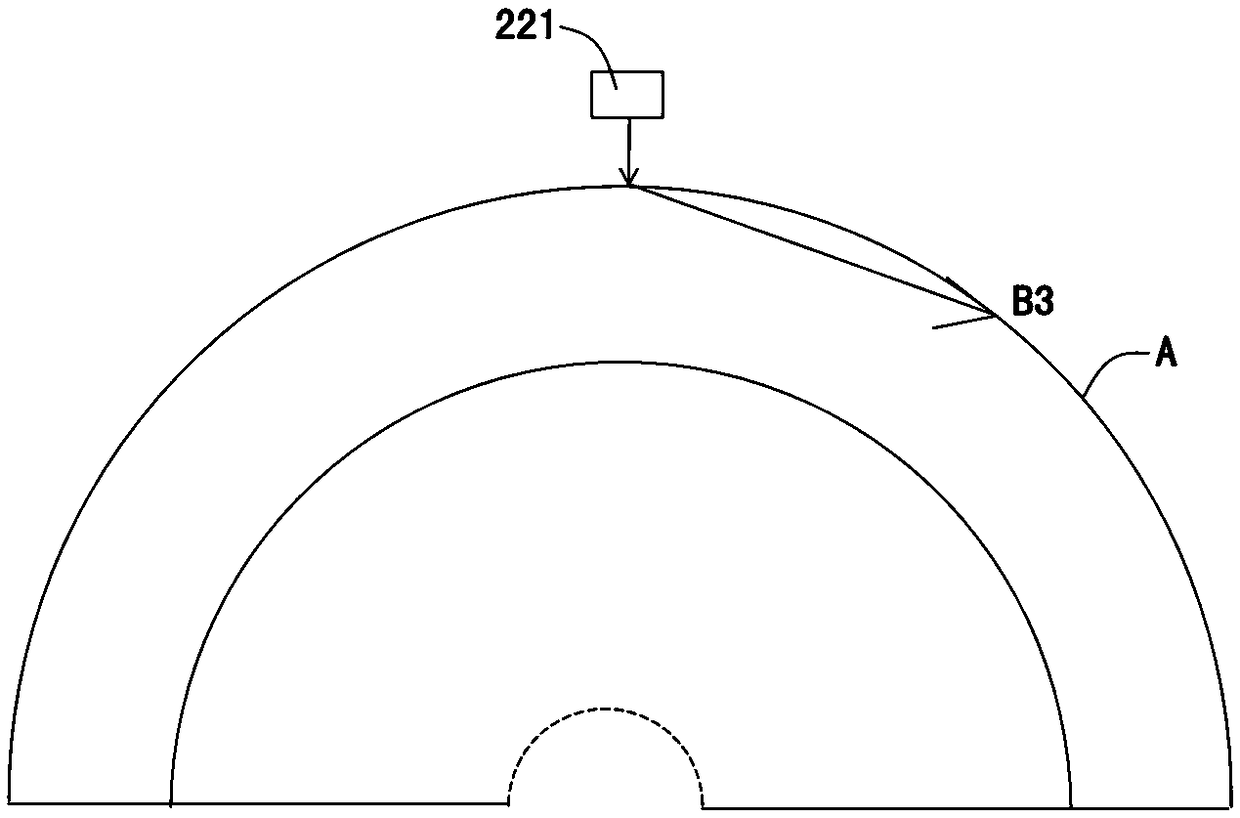

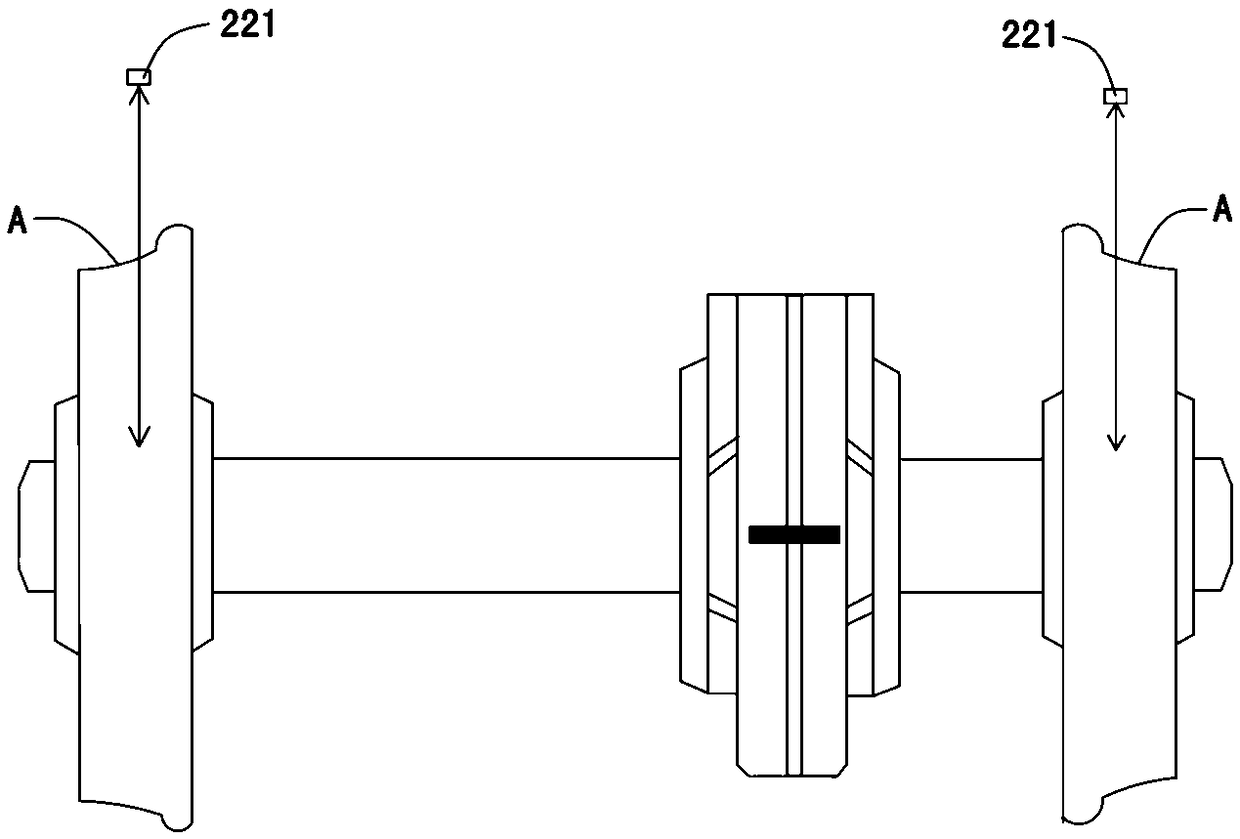

[0040] Such as figure 2 As shown, the vehicle-mounted wheelset flaw detection system of this embodiment includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com