A method and device for testing the difference in infrared emission between the front and back of textiles

A technology of infrared emission and textiles, which is applied in the direction of transmittance measurement, scattering characteristic measurement, etc., can solve the problems of not being able to characterize the dynamic interaction process between fabrics and infrared radiation, not being able to directly characterize the infrared radiation characteristics of fabrics, and having a large influence of subjective sensory factors, etc., to achieve Simple structure, convenient operation, fast measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

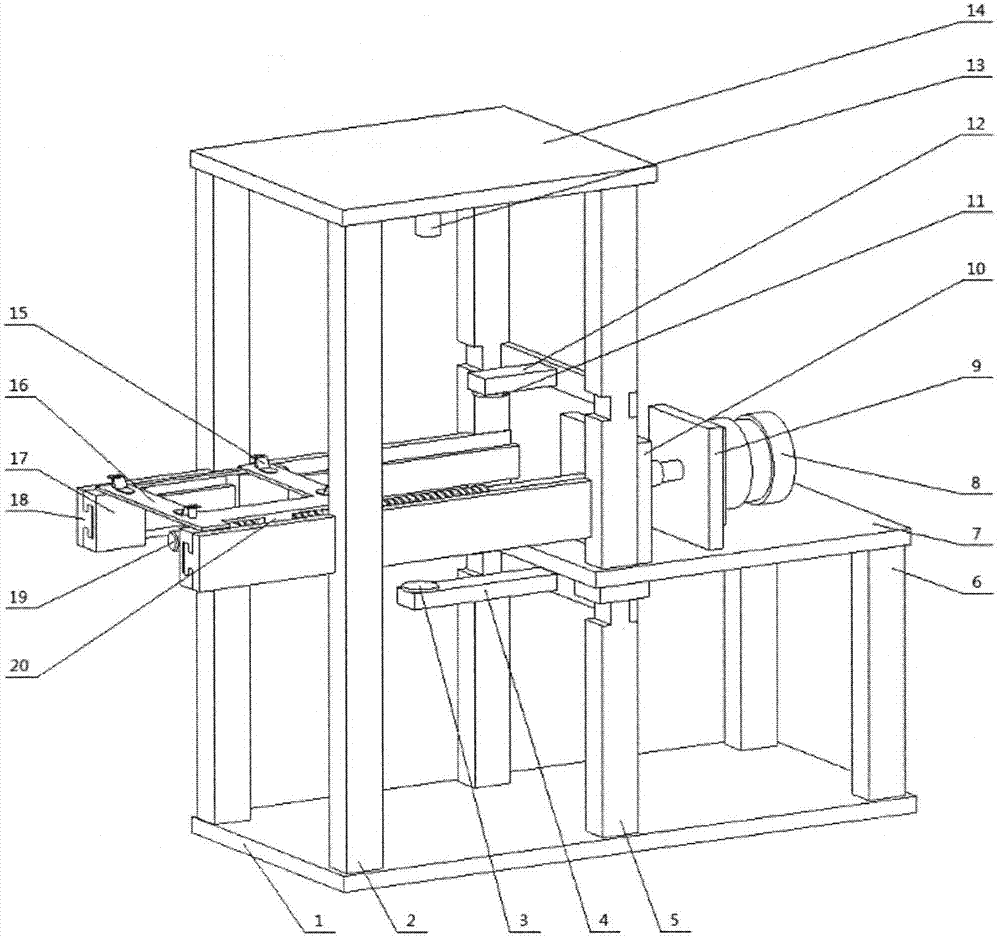

[0017] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

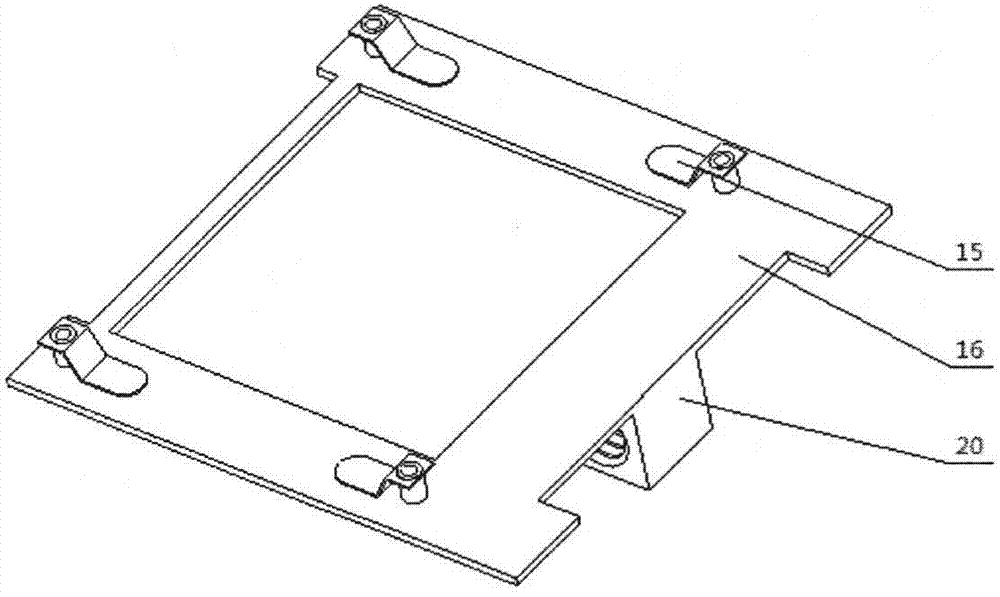

[0018] like figure 1 , 2 As shown, a device for testing the difference in infrared emission between the front and back of textiles includes a bracket part, a horizontal movement part, and a testing part. 1, the motor support plate 7 is composed of two top plate support columns 2 vertically arranged on the two corners on the left side of the long side of the bottom plate 1, and two measuring arm support columns 5 are vertically arranged at the middle position of the bottom plate 1, and the center of the measurement arm support column 5 is biased. There is a boss at the lower position, and there is a groove on the upper and lower sides of the boss. The top plate support column 2 and the measuring arm support column 5 are at the same height when the bottom plate 1 is horizontal. , the right side of the bottom plate 1 is vertically provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com