Tension detection device and detection method during tow line traveling

A technology of tension detection and tow, applied in the direction of tension measurement, etc., can solve the problem that the thread tension detection device cannot perform continuous detection, etc., and achieve the effect of contributing to the control of production quality, the device occupies a small space, and the test is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

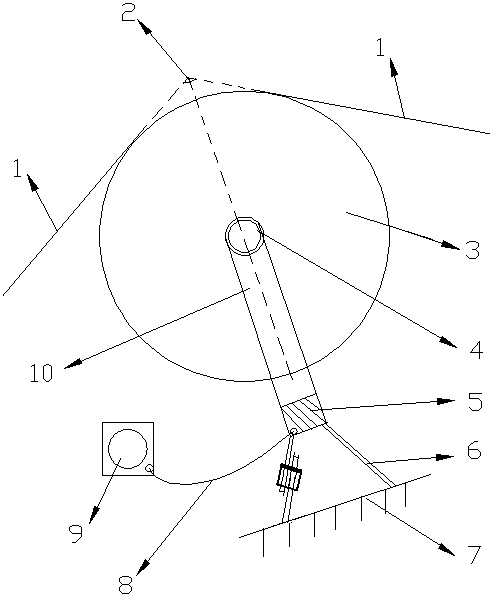

[0020] As shown in the accompanying drawing, the tension detection device in the running of the tow line adopts a set of support frames with a cantilever structure at both ends of the guide roller end face 3 before the tow 1 enters the crimping machine, and each set of support frames contains a connecting frame. Part 10 and a supporting part, the connecting part 10 and the roller are connected by a rolling bearing 4; the supporting part is fixedly connected on the spinning frame 7, and it is ensured that the corner 2 of the ribbon 1 is an obtuse angle of 150° when connecting; each supporting part has two Supporting feet 6, the length of a supporting foot 6 can be adjusted. An elastic full-bridge strain gauge 5 with a base length of 10 mm, a width of 5 mm, a sensitive grid length of 6 mm, and a detection range of 6-12 Newtons is also connected between the connecting part 10 and the supporting part of one group of supporting frames. The full-bridge strain gage 5 is then connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com