Optical bragg grating six-dimension-force sensor, as well as main body structure and measurement method thereof

A six-dimensional force sensor and fiber grating technology, applied in the field of sensors, can solve problems such as large zero point drift, weak electric signals are difficult to resist electromagnetic interference, and reduce the measurement accuracy of sensors, achieving good symmetry and realizing self-decoupling measurement of three-dimensional force and Three-dimensional moment, the effect of quantity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

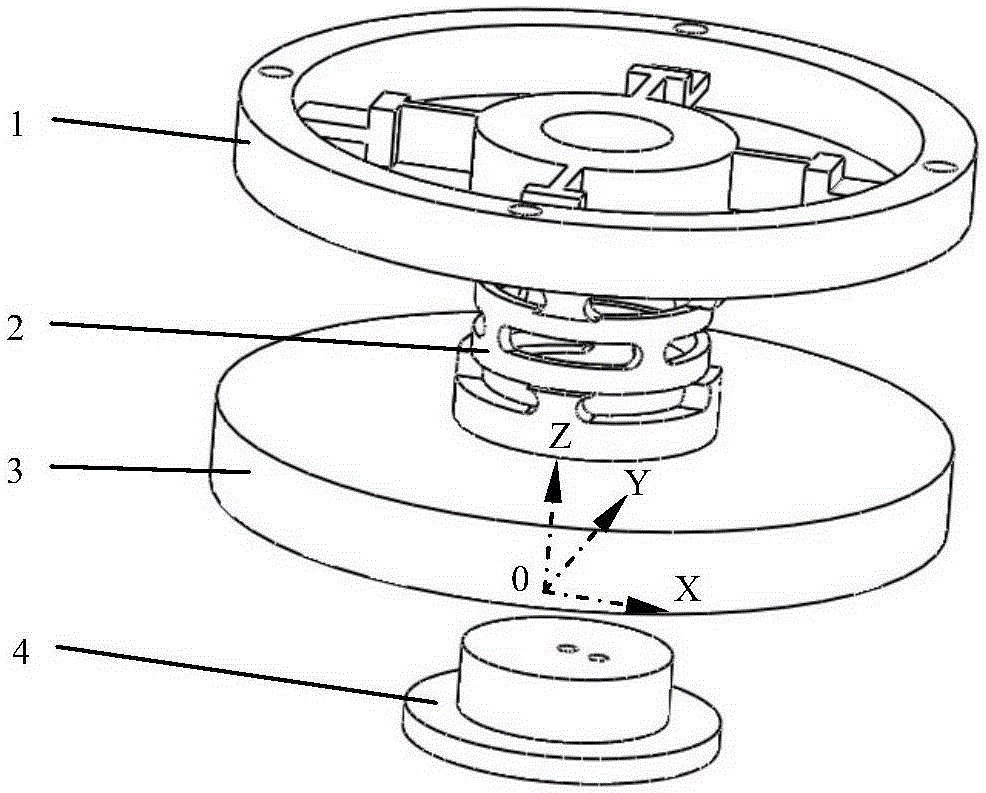

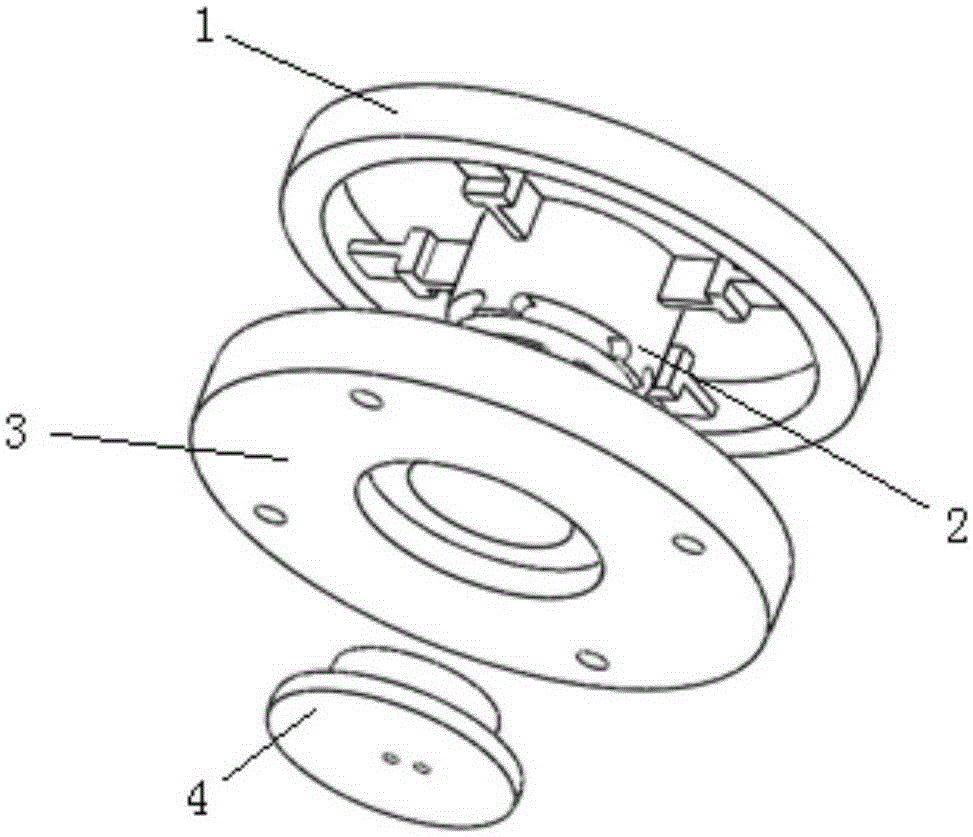

[0044] like figure 1 As shown, the sensor includes a main structure and a sensitive detection element.

[0045] The main structure includes an upper elastic disc 1 , a lower elastic cylinder 2 , a base 3 and a blocking cover 4 .

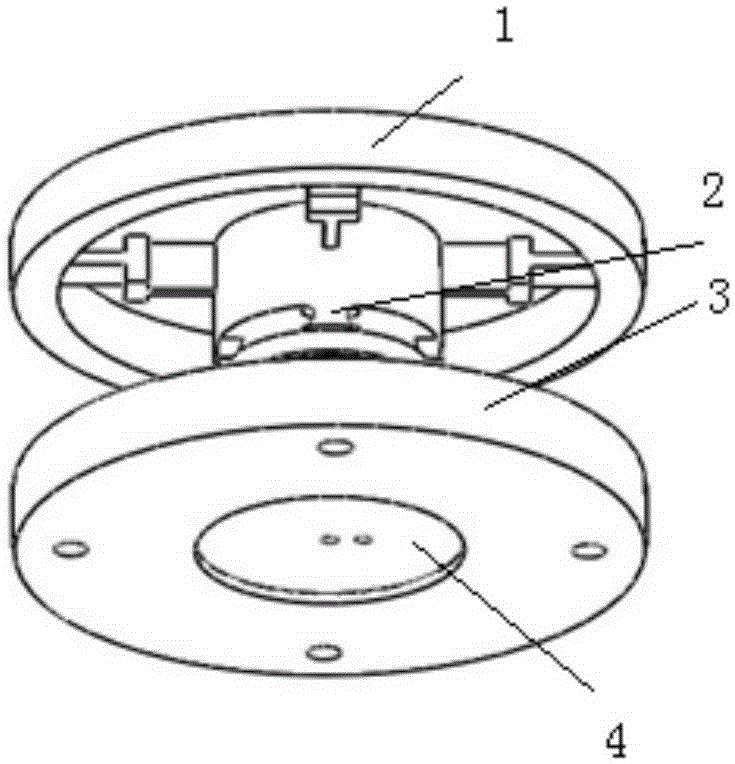

[0046] Among them, the upper elastic plate 1, the lower elastic cylinder 2 and the base 3 are integrally processed to form an integral elastic structure. The sealing cover 4 is an independent part, which is fixed by laser spot welding after matching with the hole below the base 3. The sealing cover 4 It only plays the role of fixing the optical fiber and leading out the pigtail, but has no elastic deformation function. image 3 It is a schematic diagram of the sensor after assembly and fixing.

[0047] like figure 1 In the mark, the main structure has the first axis, the second axis and the third axis perpendicular to each other to form a three-dimensional coordinate system (that is, an XYZ three-dimensional coordinate system is defined with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com