Monitoring system and monitoring method for real-time exhaust of diesel mine locomotive

A technology for diesel locomotives and monitoring systems, applied in exhaust treatment, mechanical equipment, exhaust devices, etc., can solve the problem that emission performance cannot accurately and objectively reflect vehicle emission indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

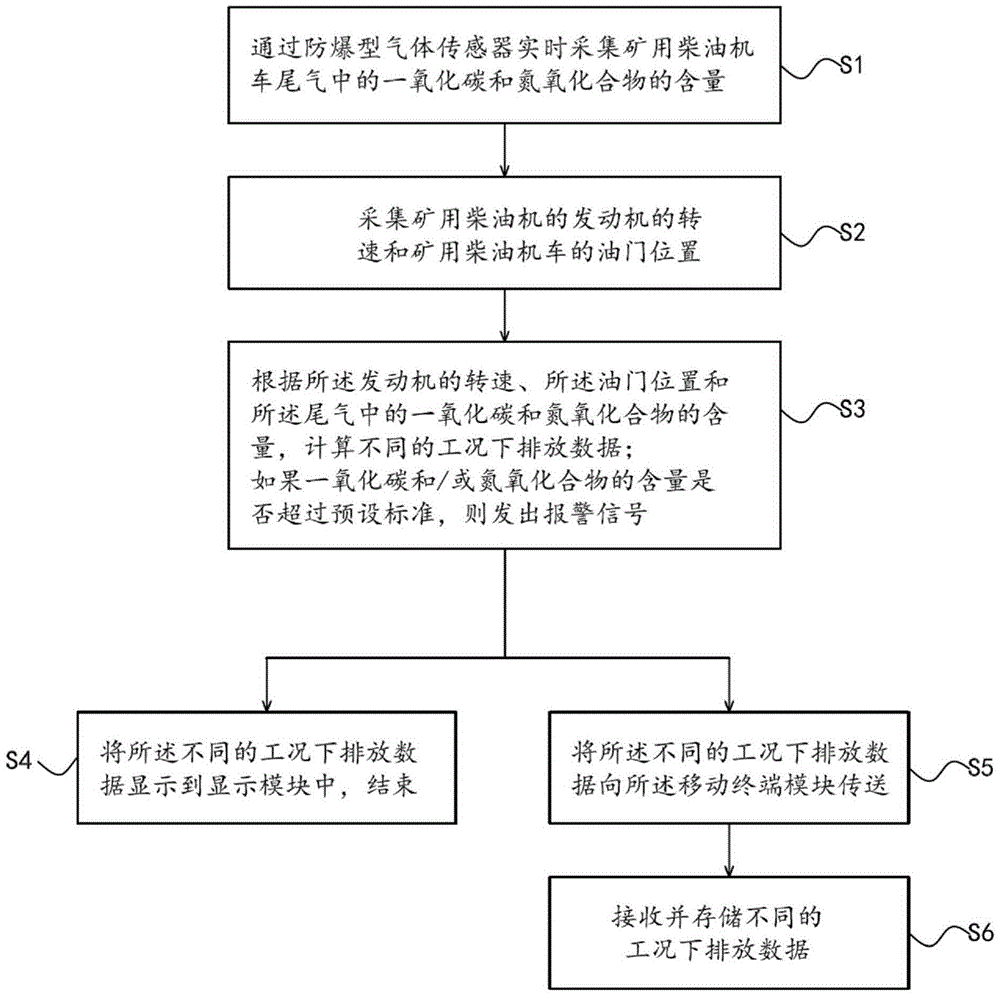

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

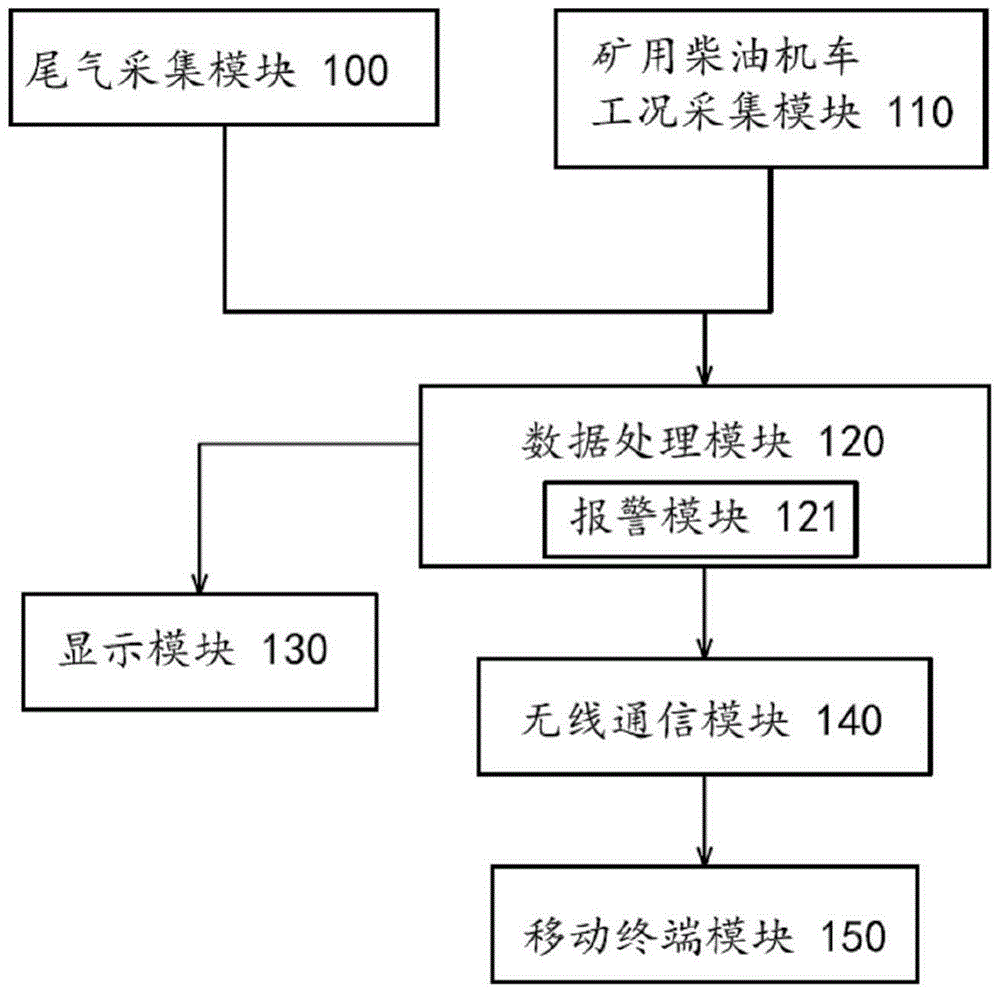

[0045] For the structural block diagram of the mining diesel locomotive real-time emission monitoring system of the present invention, see figure 1 ,

[0046] The present invention provides a real-time emission monitoring system for mining diesel locomotives, including an exhaust gas collection module 100 , a mining diesel locomotive working condition collection module 110 , a data processing module 120 , a display module 130 , a wireless communication module 140 and a mobile terminal module 150 .

[0047] Exhaust gas acquisition module 100 is used to collect the content of carbon monoxide and nitrogen oxides in the exhaust gas of mining diesel locomotives in real time through explosion-proof gas sensors, and convert the gas concentration into analog or digital quantities for use by the data processing module; The locomotive working condition collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com