Production logging manifold packer

A packer and flow-collection technology, which is applied in sealing/isolation, measurement, wellbore/well components, etc., can solve inaccurate measurement data, inconvenient maintenance, unreliable work of production logging flow-collecting packers, etc. problem, to achieve the effect of accurate measurement data, convenient maintenance and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

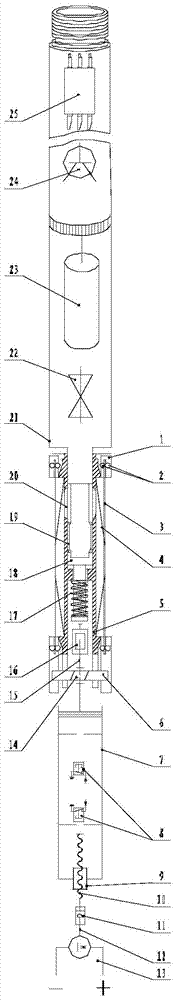

[0009] The present invention will be further described below in conjunction with accompanying drawing:

[0010] Depend on figure 1 As shown, a production logging header packer includes a housing, a DC geared motor 12, an elastic support piece 3 and a packing cloth 4, and the output shaft of the DC geared motor 12 is connected through a movable coupling 11 A ball screw 10, the ball screw 10 is externally connected with a ball screw nut 9, after the DC reduction motor 12 is started, the ball screw 10 can be driven to rotate through the movable coupling 11, and the ball screw nut 9 can be used to rotate the ball screw The rotational motion of the ball screw 10 becomes linear motion. The ball screw nut 9 is externally fixed with a two-way push-pull plate 7. The two-way push-pull plate 7 is two oppositely arranged vertical flat plates. The upper and lower ends of the two flat plates are respectively provided with a top plate and a bottom plate, wherein the bottom plate and the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com