A high-efficiency impurity removal and inspection machine

A cloth inspection machine, high-efficiency technology, applied in the direction of dryer, mechanical cleaning, high-pressure cleaning, etc., can solve the problems of unsatisfactory results of cloth inspection and winding forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

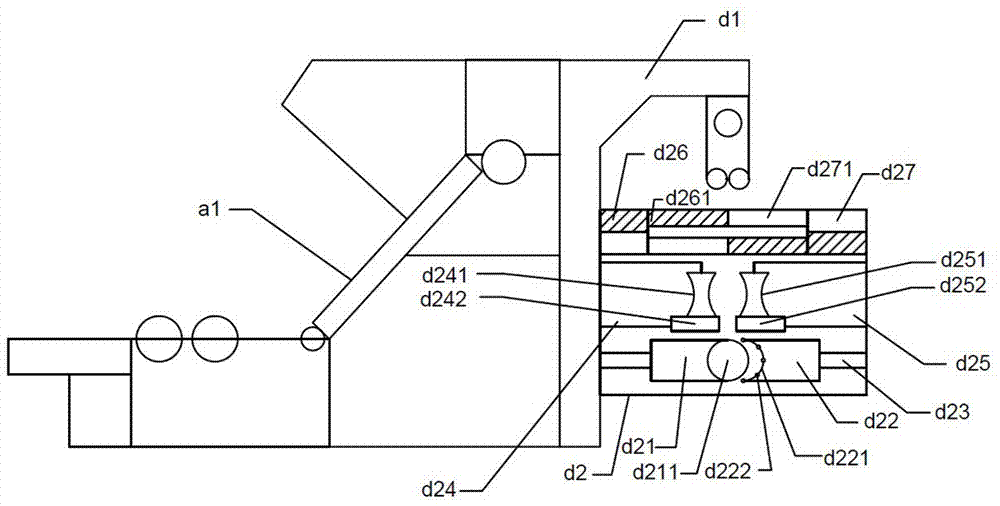

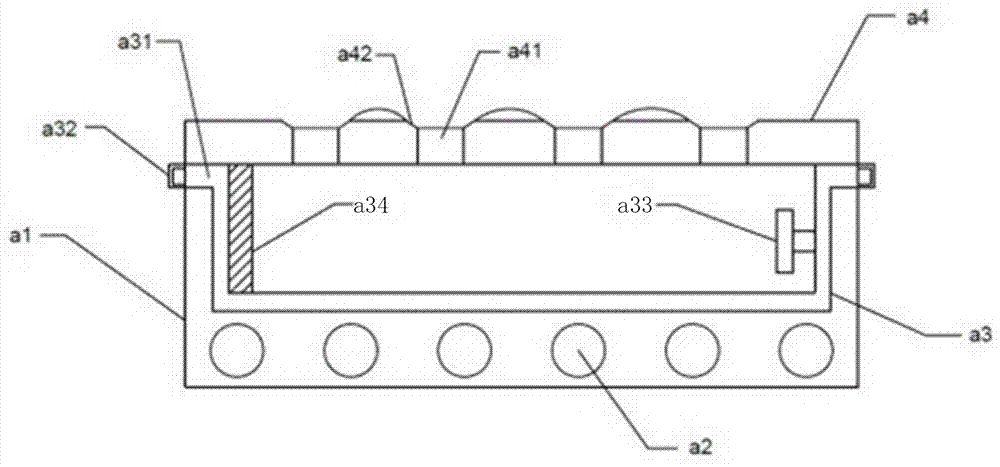

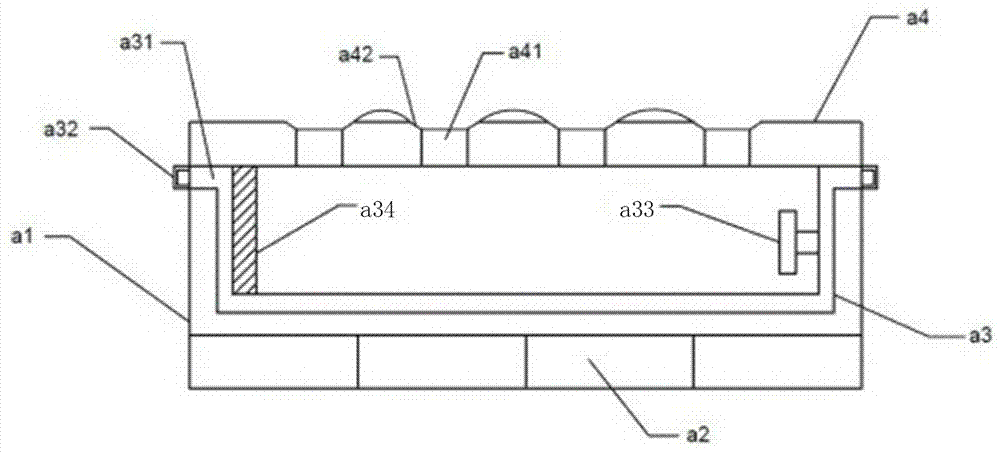

[0021] See figure 1 , figure 2 , image 3 , a high-efficiency cloth inspection machine for removing impurities, including a body, a cloth feeding frame d1 connected to the body, and a cloth inspection platform installed on the body, and also includes a removing machine box d2 arranged in front of the station d1 of the cloth feeding frame. There are cloth surface drying mechanism, cloth surface demetallization mechanism and cloth surface destaticizing mechanism in the cabinet d2, and the cloth surface drying mechanism, cloth surface demetallization mechanism and cloth surface destaticizing mechanism are close to the cloth feeding frame d1 in sequence according to the aforementioned order; the cloth inspection table includes It includes the fabric inspection box a1, the bottom fabric inspection lamp a2 set in the fabric inspection box a1, the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com