Alkylsiloxane-olefin random copolymer and its preparation method and application

A technology of alkyl siloxane and random copolymer, which is applied in the field of alkyl siloxane-olefin random copolymer and its preparation, can solve the problems of poisoning transition metal catalysts, etc., and achieve easy structure and good compatibility , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

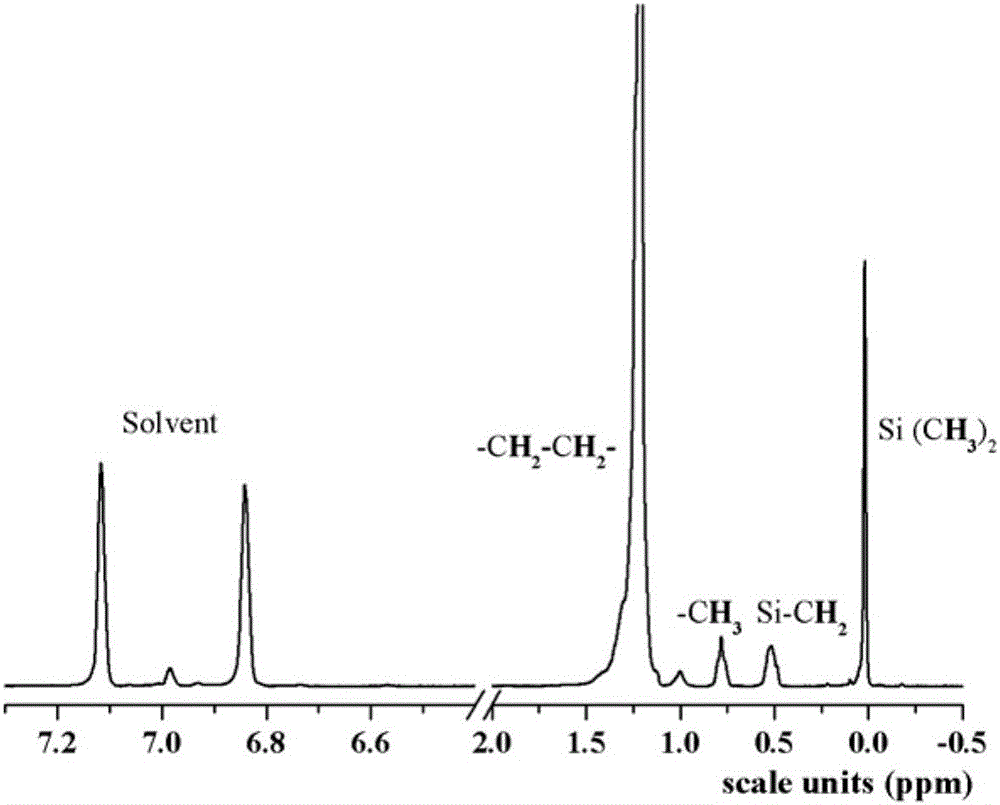

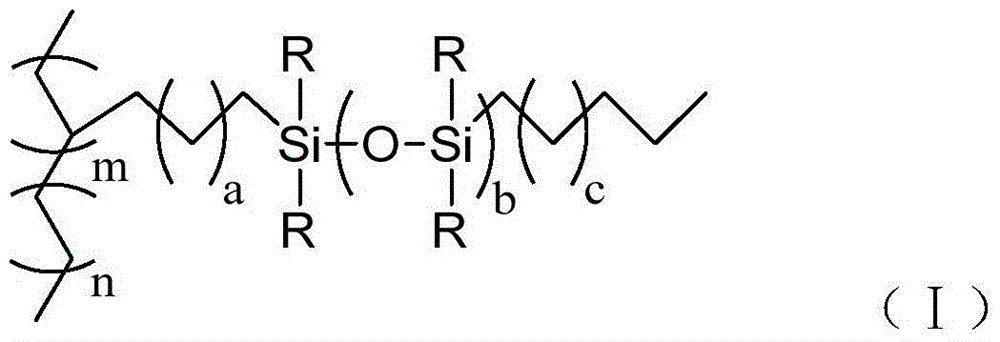

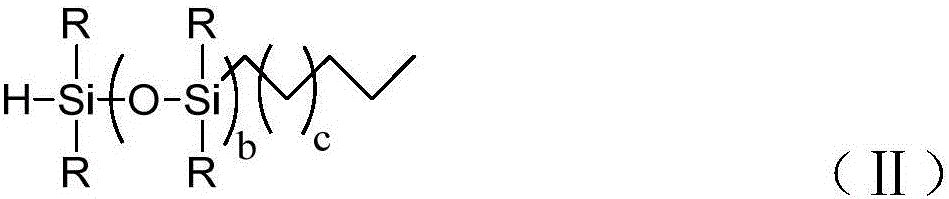

[0037] (1) Add 92g (0.69mol) tetramethyldisiloxane, 25.6g (0.23mol) 1-octene and 50g toluene to a 250mL flask equipped with a magnetic stirrer, condensing reflux device and gas inlet tube. After the device is filled with nitrogen, add 0.067g (30ppm) Karstedt catalyst solution (the mass concentration of platinum is 2%), heat to 60-80°C and stir for 8h. After the device is cooled, post-treatment removes unreacted tetramethyldisiloxane, toluene and Karstedt catalyst, and the obtained colorless transparent liquid is monohydrogen-terminated alkylsiloxane. The conversion rate was 47%. According to the characterization of the hydrogen NMR spectrum, it can be seen that in the monohydrogen-terminated alkylsiloxane, b=1 and c=4.

[0038] (2) Add 50g (0.2mol) of monohydrogen-terminated alkylsiloxane obtained in step (1), 67.1g (0.61mol) of 1,7-octadiene and 50g of toluene to a device equipped with a stirrer, condensing In the flask of the reflux device and the inlet pipe, when the devi...

Embodiment 2

[0041] Repeat the steps of Example 1, except that the amount of double-bond-terminated alkylsiloxane added in step (3) is 11.4 g (320 mmol / L). The final product was confirmed as a random copolymer with alkylsiloxane branches and olefin backbone by H NMR and IR spectroscopy. According to nuclear magnetic analysis, the molar content of the alkylsiloxane component in the copolymer is 7.8%. The copolymer had a Mw of 42400 g / mol as determined by GPC analysis.

Embodiment 3

[0043] The procedure of Example 1 was repeated except that the siloxane added in step (1) was 1,1,3,3,5,5-hexamethyltrisiloxane (143.5 g, 0.69 mol). The product of step (1) is monohydrogen-terminated alkylsiloxane. The conversion rate was 45%. It can be seen from the characterization of the hydrogen NMR spectrum that b=2 and c=4 in the monohydrogen-terminated alkylsiloxane.

[0044] The addition amount of the monohydrogen-terminated alkylsiloxane in step (2) becomes 63.7 g (0.2 mol). The product of step (2) is the double bond-terminated alkylsiloxane. The conversion rate was 57%. It can be seen from the characterization of the hydrogen NMR spectrum that a=4, b=2, and c=4 in the double bond-terminated alkylsiloxane.

[0045] The addition amount of the double-bond-terminated alkylsiloxane in step (3) becomes 6.9 g (160 mmol / L). The final product was confirmed as a random copolymer with alkylsiloxane branches and olefin backbone by H NMR and IR spectroscopy. According to nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com