Crane hoisting mechanism with anti-falling type hand-operating device for nuclear power station

A manual device and hoisting mechanism technology, applied in the direction of the spring mechanism, the hoisting device, etc., can solve the problems of large occupied space, complex structure, can not automatically prevent the load from falling by itself, etc., and achieve the effect of convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

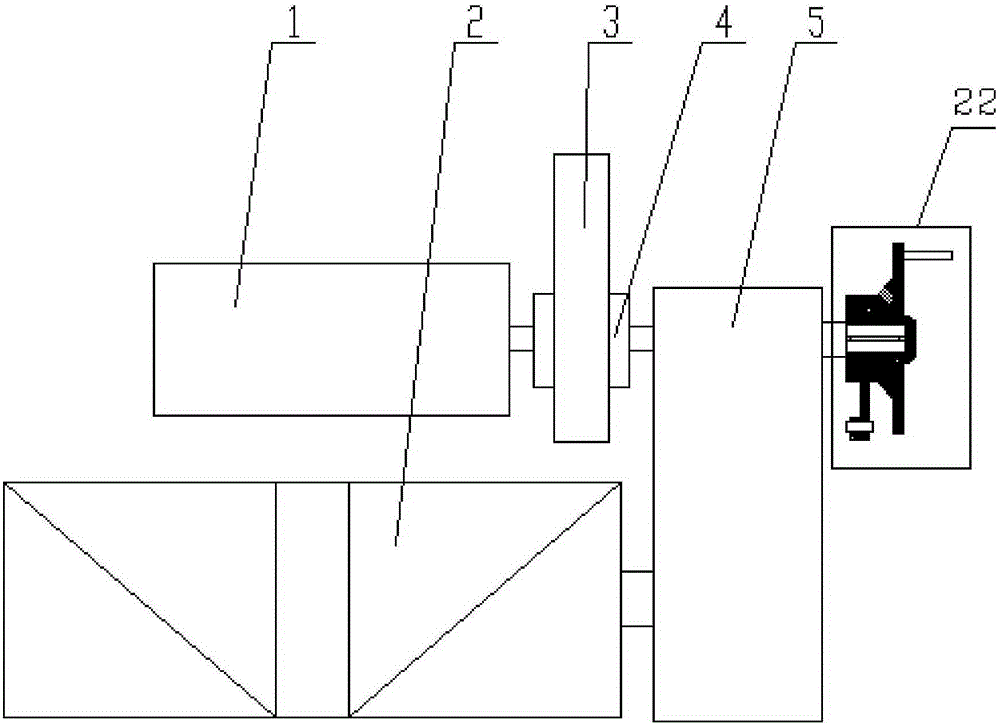

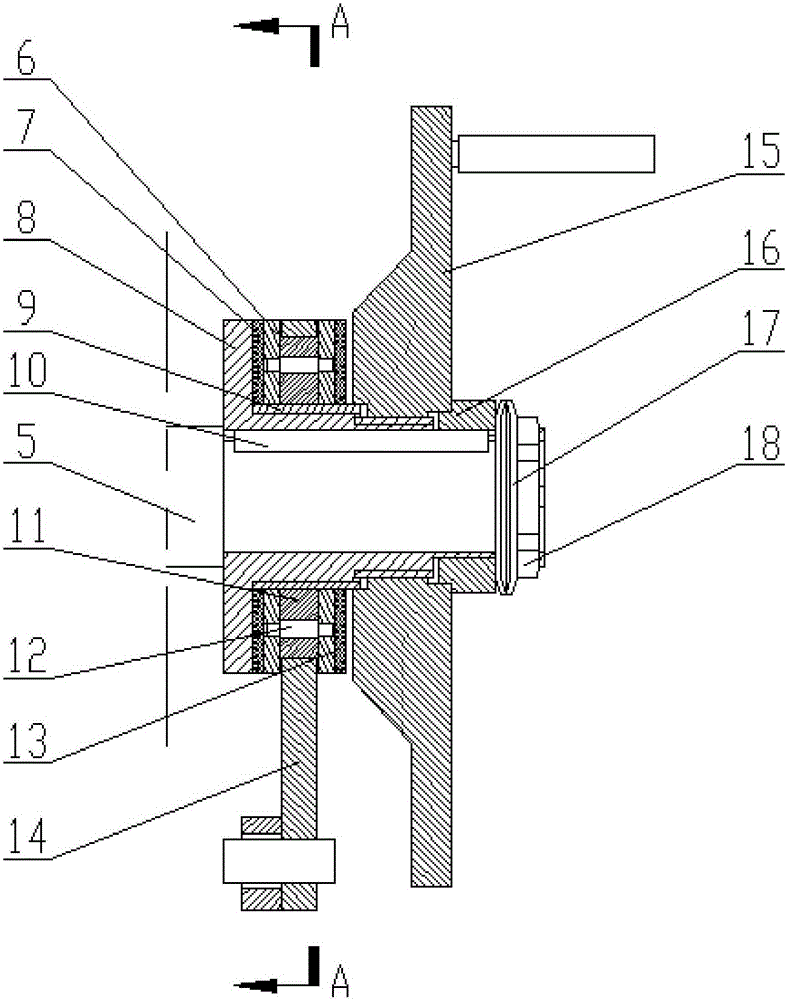

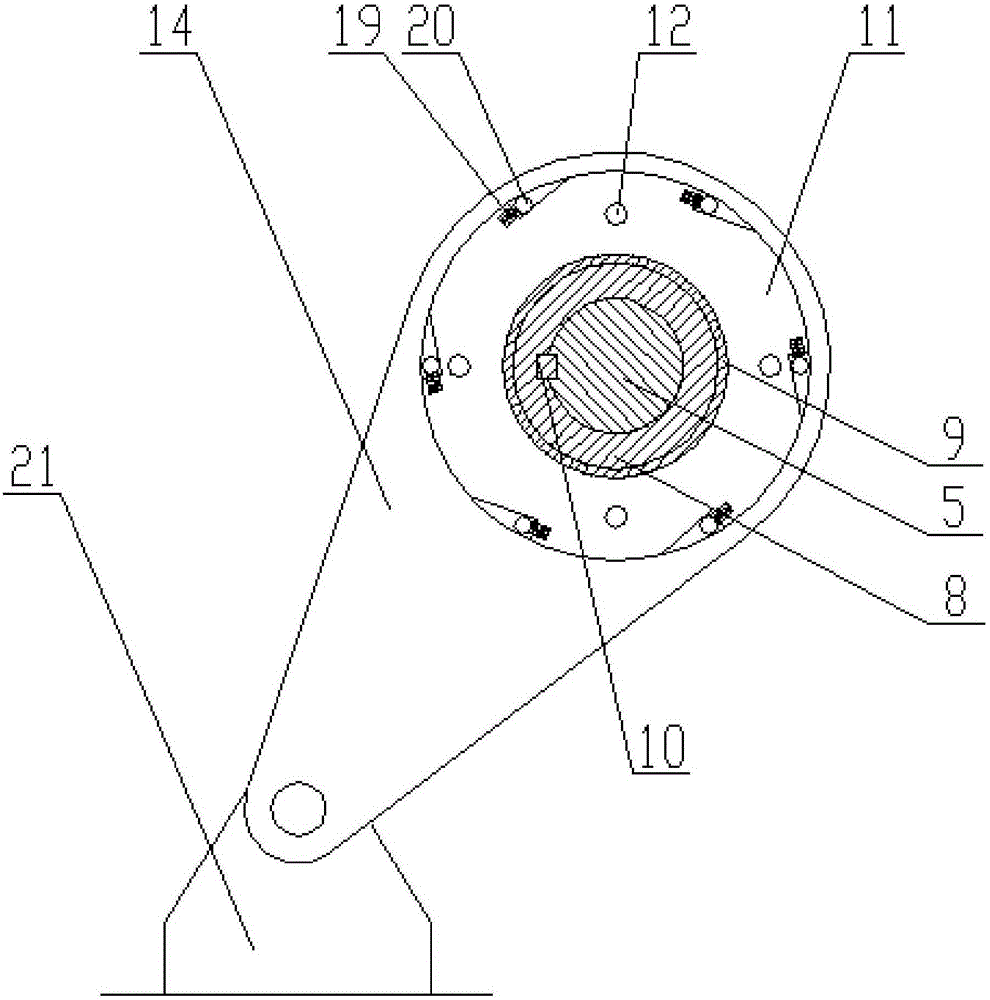

[0022] The lifting mechanism of a nuclear power plant crane with a fall-prevention manual device includes a motor 1, a reel set 2, a brake 3, a brake wheel coupling 4, a reducer 5 and a handle mechanism 22, and the motor 1 passes through the brake 3 and the reducer 5 connection, the two brake wheel couplings 4 are respectively connected between the motor 1 and the brake 3 and between the brake 3 and the reducer 5; the handle mechanism 22 includes a friction plate 6, a friction plate 17, a flange 8, a shaft sleeve 9, Key 10, fixed plate 11, fixed pin 12, friction plate II13, fixed flange 14, hand wheel 15, stop ring 16, disc spring 17, nut 18, spring 19, roller 20 and fixed seat 21, friction plate 6 is Circular plate, friction plate 6 has a central hole; fixed plate 11 is a circular plate, fixed plate 11 has a central hole, fixed plate 11 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com