tail lift

A tailgate and lifting device technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of increasing vehicle manufacturing cost, complicated tailgate structure, and increasing vehicle load, so as to improve stability, convenience, and height The effect of high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

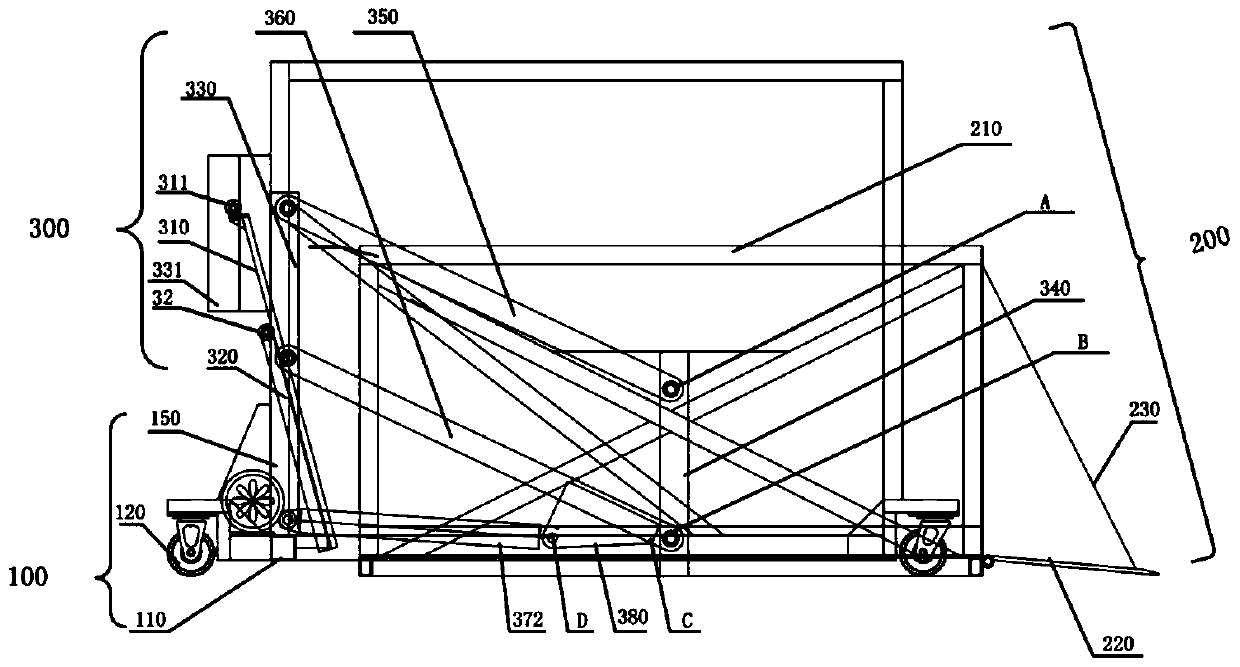

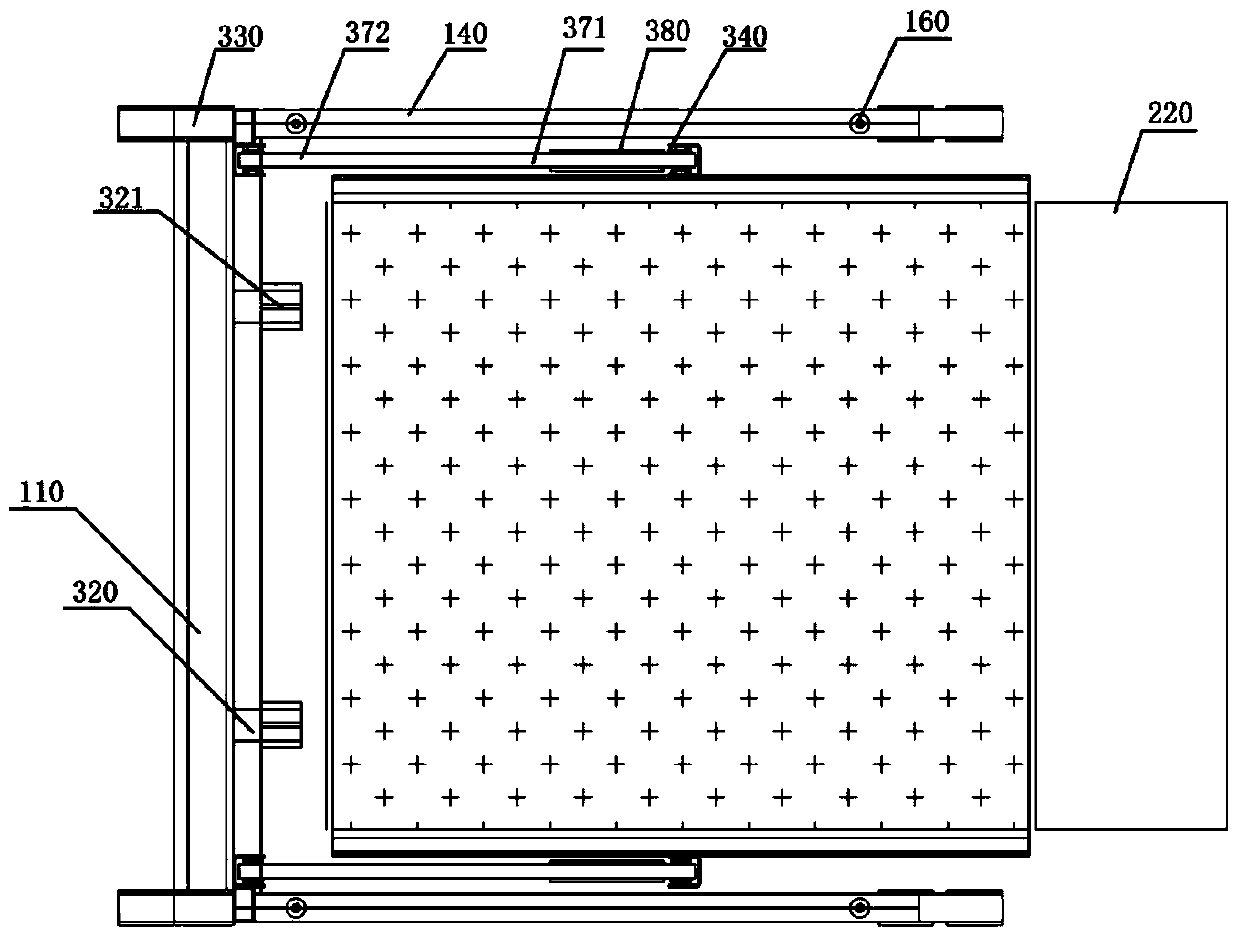

[0039] Figure 1-4 It is a kind of realization mode of the lifting tailgate described in the present invention, by figure 1 and figure 2 It can be seen that the tail lift described in the present invention includes: a base 100 , a platform 200 and a lifting device 300 .

[0040] The platform 200 is provided with a first guardrail 210 , a board 220 and a chain 230 . The first guardrail 210 is a pair, vertically arranged on the parallel sides of the platform 200, for protection; the board 220 is a pair, arranged on the other two sides of the platform 200, and one end of the board 220 is rotatably connected to the platform 200, the other One end is connected to the first guardrail 210 by a chain 230 .

[0041] The lifting device 300 is connected to the base 100 and the platform 200, respectively. Lifting device 300 comprises telescopic positioning bar 310 and is provided with chute 321 (as Figure 4 Shown) the support column 320. One end of the support column 320 is connec...

Embodiment 2

[0055] On the basis of Embodiment 1, this embodiment provides a method of applying the lift tailgate in Embodiment 1 to carry out loading and unloading in sequence, as follows:

[0056] First, fix the lift tailgate: after the vehicle stops, move the lift tailgate to the rear of the vehicle so that the anti-collision rubber 331 is against the rear of the vehicle; adjust the screw 160 so that the casters 120 are off the ground and the screw 160 is on the same horizontal position. In this step, the anti-collision rubber 331 reduces the loss caused by the collision when the rear of the vehicle contacts the tailgate, and the screw rod 160 plays a good role in fixing the tailgate to prevent the danger caused by the movement of the tailgate during use.

[0057] Secondly, by adjusting the telescopic length of the telescopic positioning rod 310, adjust the height of the lap board 220 to be overlapped: after the telescopic positioning rod 310 is stretched in the chute 321 to the same he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com