Medical cleaning rack

A technology for cleaning racks and flushing plates, applied in the field of medical cleaning racks, can solve the problem of high cost, and achieve the effects of improving service life, reducing the use of materials, and improving work stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

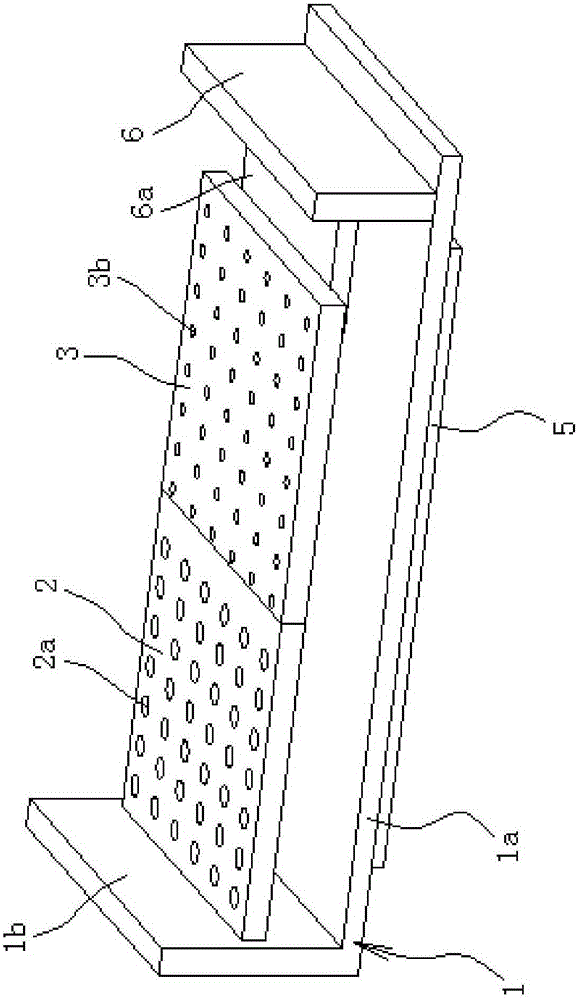

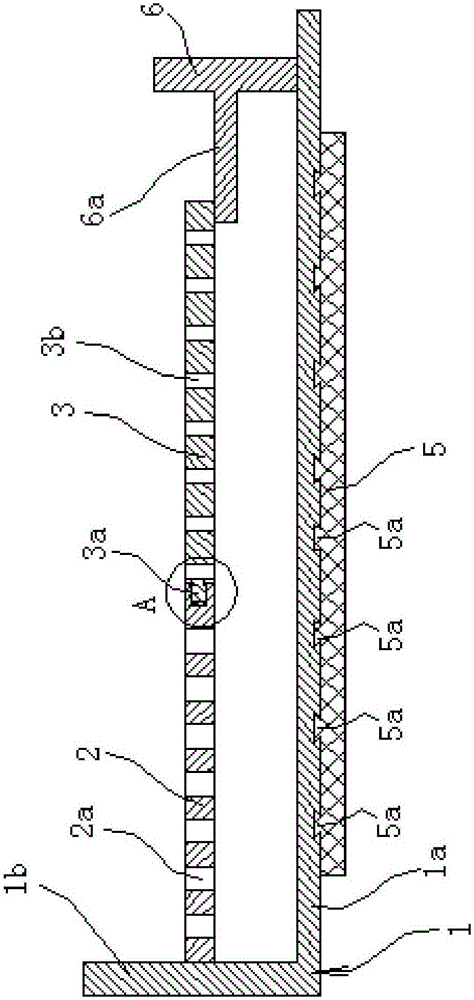

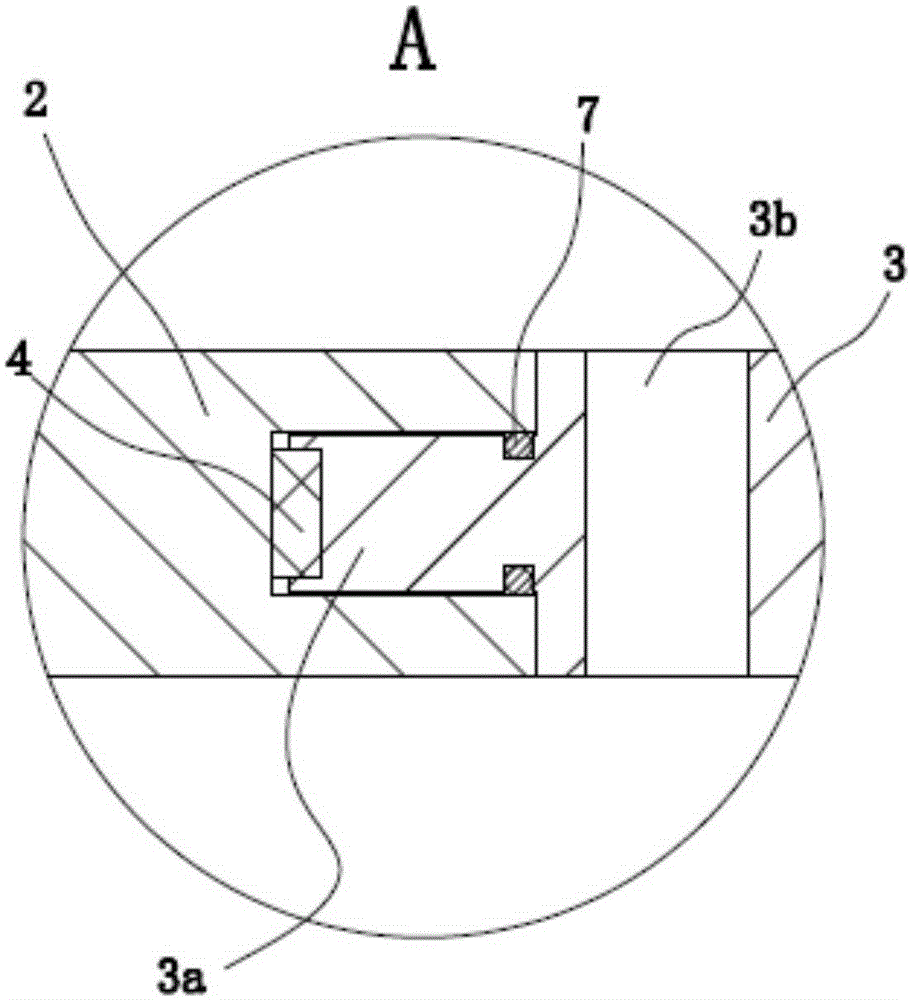

[0036] Such as Figure 1 to Figure 3 Shown, this medical cleaning stand is made up of support 1, flushing plate one 2, flushing plate two 3, magnet 4, rubber pad 5, connecting plate 6 etc. Wherein, the first flushing plate 2 and the second flushing plate 3 are made of magnetically permeable materials, and the magnetically permeable materials can be steel, nickel-iron alloys, and the like. Preferably, both the first flushing plate 2 and the second flushing plate 3 are made of steel.

[0037] The support 1 is L-shaped, and the support 1 includes a horizontal support part 1a and a vertical fixation part 1b, and both the support part 1a and the fixation part 1b are in the shape of a long plate. A rubber pad 5 is attached to the lower side of the support portion 1a, and the rubber pad 5 is fixed to the support portion 1a through a concave-convex connection structure, so that the support portion 1a contacts the ground (or other support portion 1a pieces) through the rubber pad 5 ,...

Embodiment 2

[0044] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the sealing member 7 is a ring-shaped rubber layer uniformly coated on the side wall of the connecting part 3a, and the outer wall of the rubber layer is in contact with the The inner walls of the connecting holes are offset.

Embodiment 3

[0046] The structure and principle of this third embodiment are basically the same as that of the first embodiment, except that the concave-convex connection structure includes a limit hole on the lower side of the support part 1a and a protruding hole on the upper side of the rubber pad 5 that is consistent with Connecting posts that match the limit holes. There are at least two limiting holes and they are evenly distributed along the circumferential direction. The limiting holes are tapered and the diameter of the limiting holes gradually decreases downward. The number of connecting columns is the same as that of the limiting holes and the positions correspond to each other, and the connecting columns are embedded in the limiting holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com