Tea grader with filter net cleaning mechanism

A classifier and filter screen technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of easily broken tea particles, affecting tea screening, easy to break tea, etc., to reduce the number of replacement containers, reduce The effect of manual participation and reduction of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

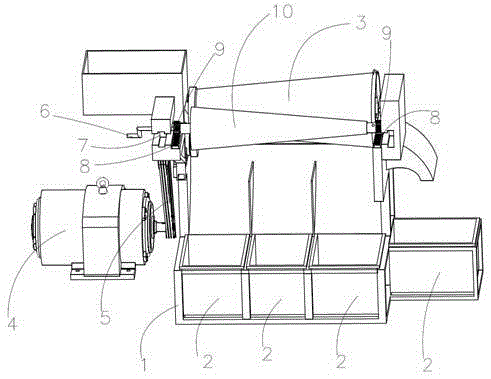

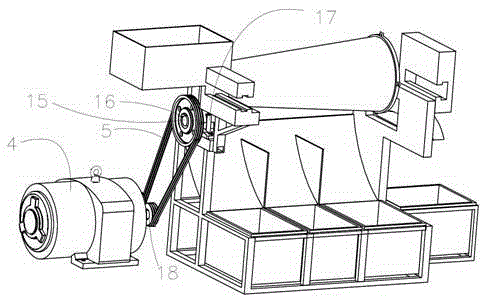

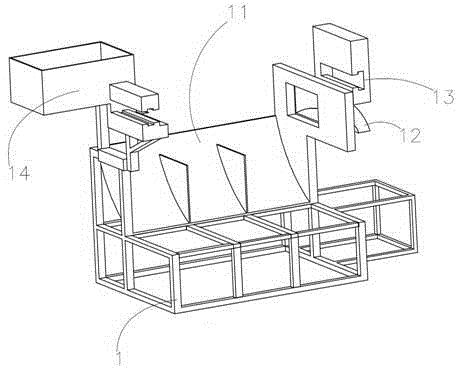

[0023] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

[0024] according to Figure 1 to Figure 4 As shown, a tea grading machine with a cleaning filter mechanism includes a frame, a driving device, a filter drum 3 and a mechanism for cleaning the filter, and the frame is welded with a feed hopper 14, a tea baffle 11, Discharge hopper 12, sorting container placement groove and track 13, four sorting container placement slots are divided into on the described frame, and four sorting containers are placed in the sorting container placement slot along the longitudinal direction, and the classification container size is the same, and the classification container edge Fitted on the frame, the filter drum 3 is arranged on the frame, one end of the filter drum 3 is connected with the feed hopper 14, and the other end is connected with the discharge hopper 12, and the bottom of the filter drum 3 is fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com