A paint mixing tank

A technology for stirring tank and paint, applied in the field of paint stirring tank, can solve the problems such as the need to improve the stirring efficiency, the uneven stirring, the large motor power, etc., and achieve the effects of facilitating subsequent cleaning, improving the support effect, and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

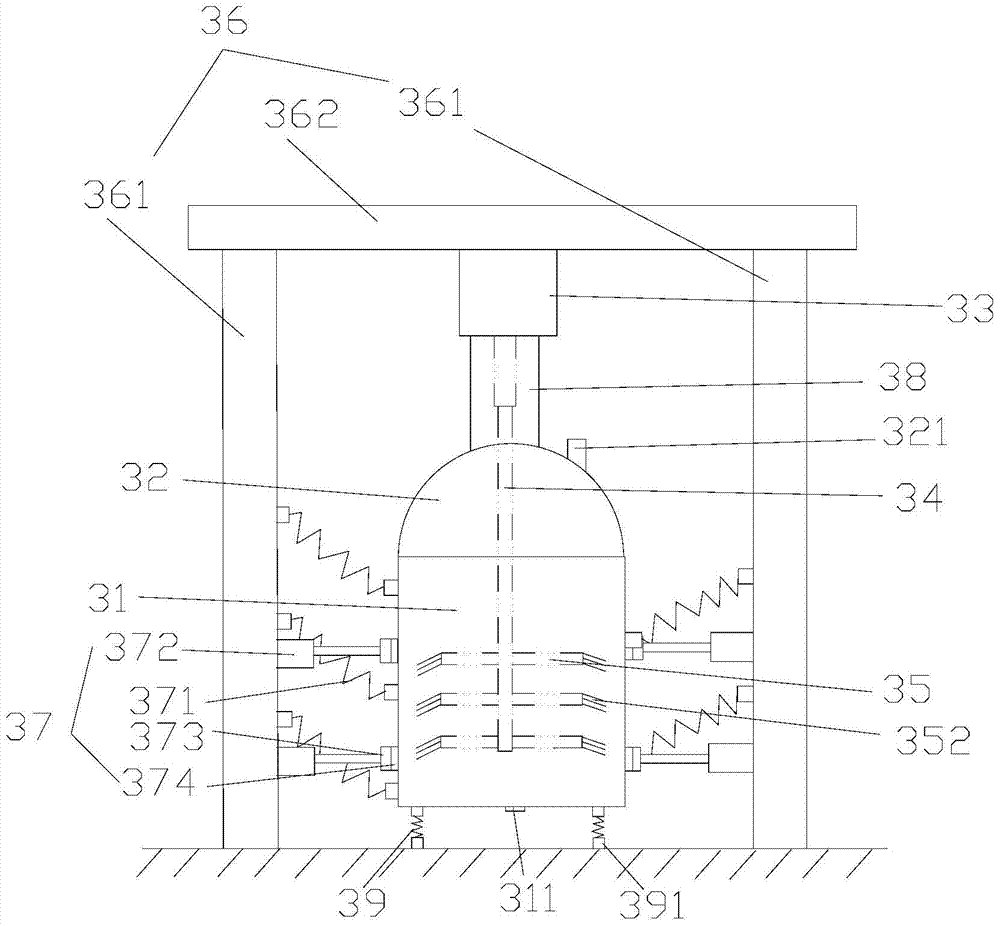

[0030] Such as figure 1 As shown, the present invention discloses a paint stirring kettle, which includes a kettle body 31 , a kettle cover 32 , a motor 33 , a rotating shaft 34 , a stirring paddle 35 , a frame 36 , a swing mechanism 37 and a rubber sleeve 38 .

[0031] The kettle cover 32 is closed on the kettle body 31, the kettle cover 32 is provided with a feed port 321, and the bottom of the kettle body 31 is provided with a discharge port 311; the frame 36 includes two Support 361 and beam 362, the two supports 361 are symmetrically arranged at both ends of the beam 362, the top of each bracket 361 is fixedly connected with the corresponding end of the beam 362, and the bottom of each bracket 361 is fixed on On the ground: when the kettle cover 32 is closed on the kettle body 31 to form an integral structure, the integral structure is limited in the through ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com