Spice mixer

A technology for mixers and spices, applied in mixers, mixers with rotating containers, solid separation, etc., can solve problems such as uneven mixing, generation of metal debris, and impact on food safety, so as to facilitate material discharge and prevent accumulation Materials, the effect of ensuring food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

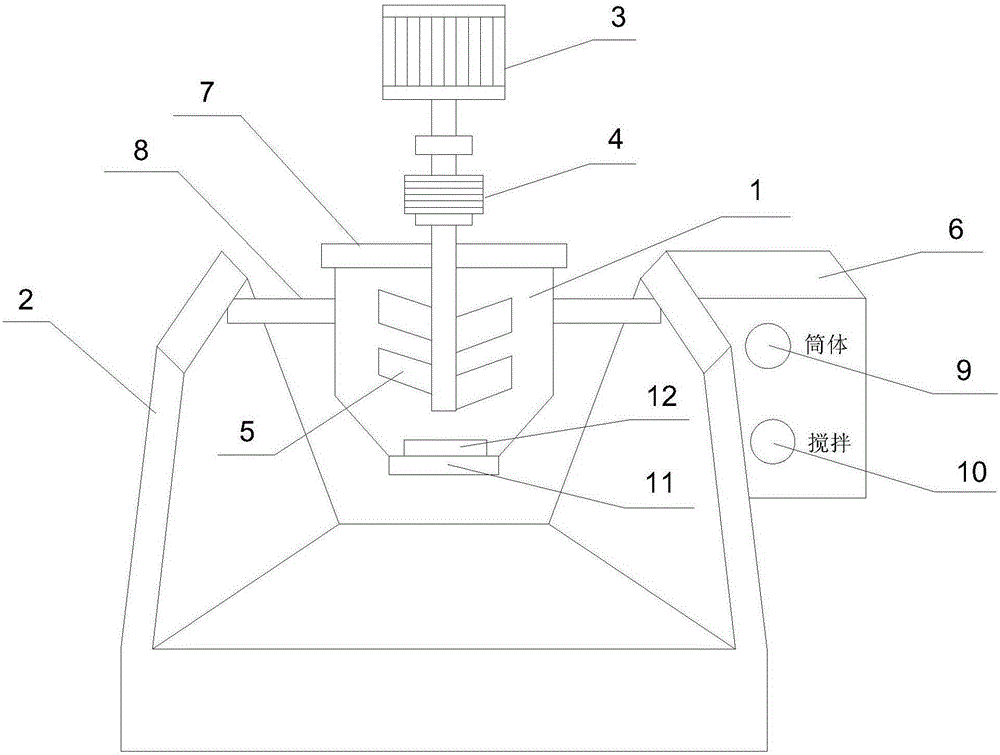

[0016] Such as figure 1 As shown, the present invention is a spice mixing machine, comprising a cylinder body 1, a frame 2, a driving device 3, a gearbox 4, a stirring tool 5, a control panel 6, and the upper part of the cylinder body 1 is a feeder with a feed cover 7. There are two transmission shafts 8 welded on both sides of the cylinder, and there are bearings at both ends of the transmission shaft 8. When installing, the transmission shafts on both sides of the cylinder 1 are fixed on the frame 2 by bolts, and the driving device 3, the speed changer The box 4 and the mixing tool 5 are connected in sequence, and the control panel 6 is fixed on the right side of the frame 2. The control panel 6 has a barrel adjustable speed switch 9 and a stirring adjustable speed switch 10, which control the barrel 1 and the stirring tool respectively. 5 rotation; cylinder body 1 lower part is the discharge opening with discharge cover 11, and the inner side of discharge cover is welded wi...

Embodiment 2

[0018] When working, there should be no other debris in the cylinder 1, open the feed cover 2, put in powder materials such as spices, and the added raw materials should not exceed 60% of the total volume of the cylinder 1; close the feed cover 2 and connect the power supply, Turn on the adjustable speed switch 9 of the cylinder to control the rotation of the cylinder 1; the driving device 3 drives the stirring knife 5 to rotate, and the rotational speed of the stirring knife 5 can be adjusted by the adjustable speed switch 10 according to actual needs; The metal impurities will be tightly adsorbed on the magnet on the surface of the stirring tool 5 during the rotation; after the work is finished, the counterweight 12 will make the barrel droop naturally, and the discharge cover 11 will be opened to discharge the mixed materials from the discharge Mouth discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com