Rotational flow reaction device and flue gas desulfurization device

A swirl reaction and flue gas technology, which is applied in the fields of swirl reaction device, flue gas desulfurization device and desulfurization device, can solve the problems of high maintenance cost, easy blockage of nozzle of spray device and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

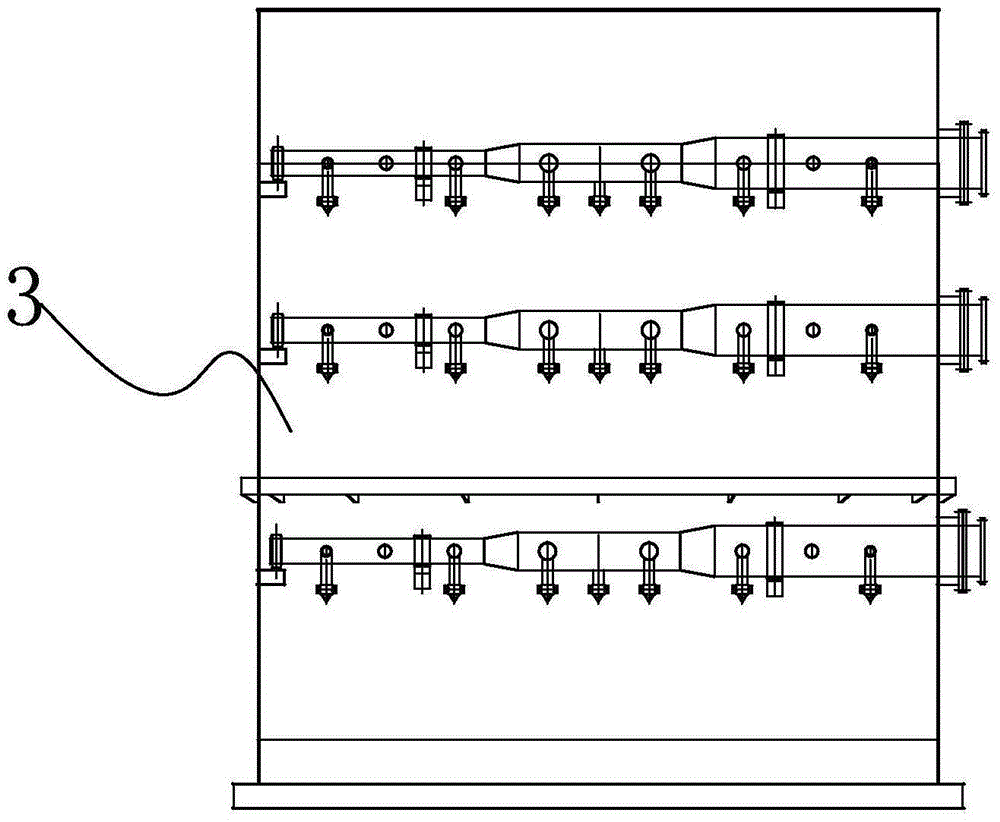

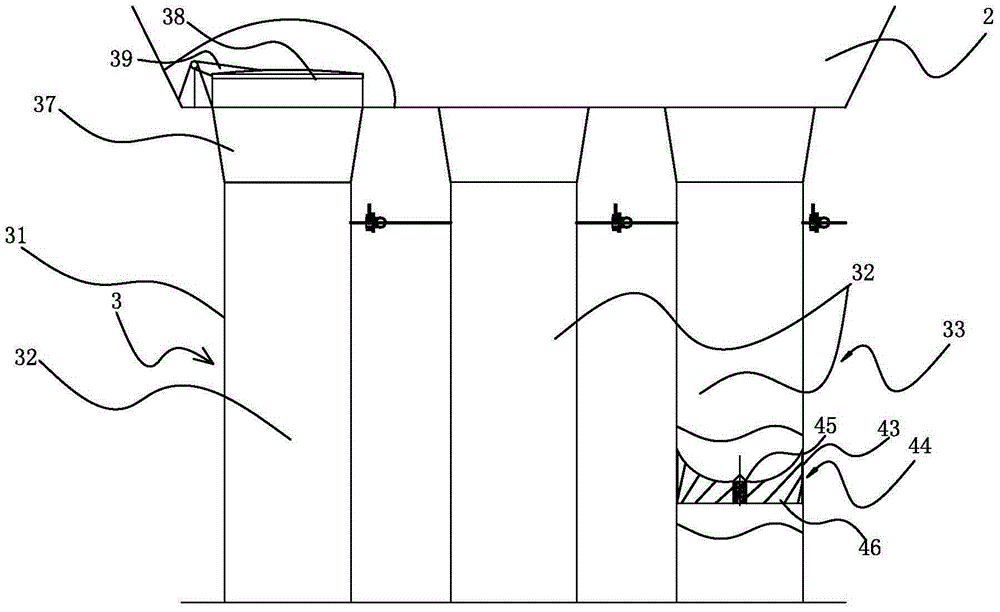

[0041] The following with attached Figure 3 to Figure 11 A cyclone reaction device and a flue gas desulfurization device of the present invention are further described in detail.

[0042] A kind of cyclone reaction device of the present invention, please refer to Figure 3 to Figure 11, comprising a swirl outer casing 31 and at least two swirl chambers 32 horizontally arranged in the swirl outer casing 31, at least one swirler 33 horizontally arranged in the swirl chamber 32, the swirl chamber 32 is provided with a circulating reaction slurry inlet 34, the swirl chamber 32 is communicated with the gas homogenizer 4 below, the swirl 33 includes a swirl impeller 44 arranged horizontally, and the swirl impeller 44 includes a The impeller casing 43, the impeller central shaft 45 arranged in the center and at least five spirally rising swirl blades 46, the swirl blades 46 are arranged around the impeller central shaft 45, the impeller casing 43 is fixed on the swirl In the chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com