A kind of harm reducer and application thereof for selectively reducing NNK in cigarette smoke

A cigarette smoke and selective technology, applied in the fields of application, tobacco, and tobacco treatment, can solve the problems of low chemical activity and NNK difficulty, and achieve the effect of low production cost, easy production and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

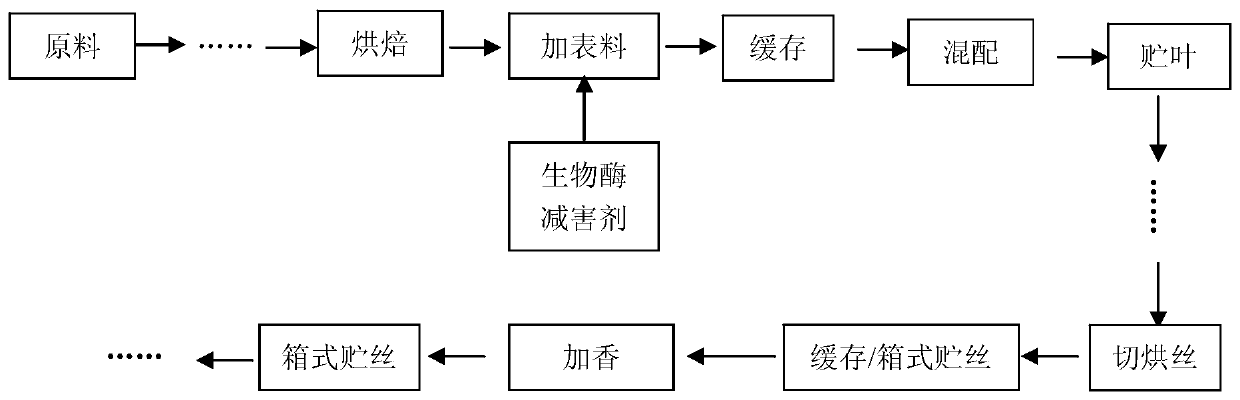

Method used

Image

Examples

Embodiment 1

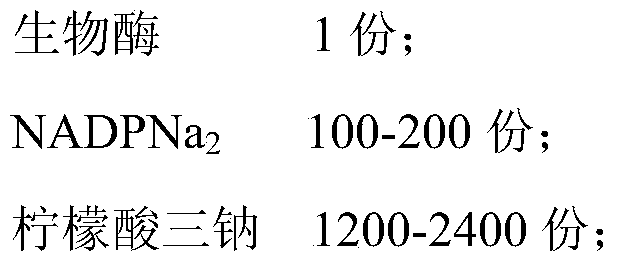

[0042] Take 1g cytochrome P450 enzyme, 100g NADPNa by weight 2 , 1200g trisodium citrate, 60g magnesium chloride, add 100kg water to dissolve and make biological enzyme harm reducer. The cytochrome P450 enzyme is selected from any one or a combination of cytochrome P450 isozymes P4501A, P4502A, P4502B, P4502C, P4502D, P4502E, P4503A, P45011A, and P45011B.

[0043] The above-mentioned biological enzyme harm reducer was mixed into the surface material tank, and in the process of adding surface material, it was sprayed on-line on 2027kg tobacco leaf samples by means of compressed air atomization. The amount of the biological enzyme harm reducer applied on the tobacco leaves is 5% of the weight of the tobacco leaves. The reaction time for the biological enzyme harm reducer to be applied to the tobacco leaves is 10 hours. After the reaction, the subsequent processing steps are carried out.

Embodiment 2

[0045] Take 1g cytochrome P450 enzyme, 200g NADPNa by weight 2 , 2400g trisodium citrate, 120g magnesium chloride, add 200kg water to dissolve and make biological enzyme harm reducer. The cytochrome P450 enzyme is selected from any one or a combination of cytochrome P450 isozymes P4501A, P4502A, P4502B, P4502C, P4502D, P4502E, P4503A, P45011A, and P45011B.

[0046]The above-mentioned biological enzyme harm reducer was mixed into the surface material tank, and in the process of adding surface material, it was sprayed on-line on 4054kg tobacco leaf samples by means of compressed air atomization. The amount of the biological enzyme harm reducer applied on the tobacco leaves is 5% of the weight of the tobacco leaves. The reaction time for the biological enzyme harm reducer to be applied to the tobacco leaves is 24 hours. After the reaction, the subsequent processing steps are carried out.

Embodiment 3

[0048] Take 1g cytochrome P450 enzyme, 100g NADPNa by weight 2 , 1200g trisodium citrate, 60g magnesium chloride, add 10kg water to dissolve and make biological enzyme harm reducer. The cytochrome P450 enzyme is selected from any one or a combination of cytochrome P450 isozymes P4501A, P4502A, P4502B, P4502C, P4502D, P4502E, P4503A, P45011A, and P45011B.

[0049] The above-mentioned bio-enzyme harm reducer was mixed into the surface material tank, and in the process of adding surface material, it was sprayed online on 1136kg tobacco leaf samples by means of compressed air atomization. The amount of the biological enzyme harm reducer applied on the tobacco leaves is 1% of the weight of the tobacco leaves. The reaction time for the biological enzyme harm reducer to be applied to the tobacco leaves is 10 hours. After the reaction, the subsequent processing steps are carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com