Large-aperture crystal frequency-doubling conversion device realizing frequency conversion and light beam focusing

A technology of frequency conversion and frequency doubling conversion, applied in light demodulation, optics, lasers, etc., can solve the problem of large-aperture laser frequency doubling conversion and focusing devices that do not have temperature control capabilities, damage crystals, and cannot monitor frequency doubling lasers online Quality and conversion efficiency and other issues, to achieve the effect of compact structure, complete functions, and convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

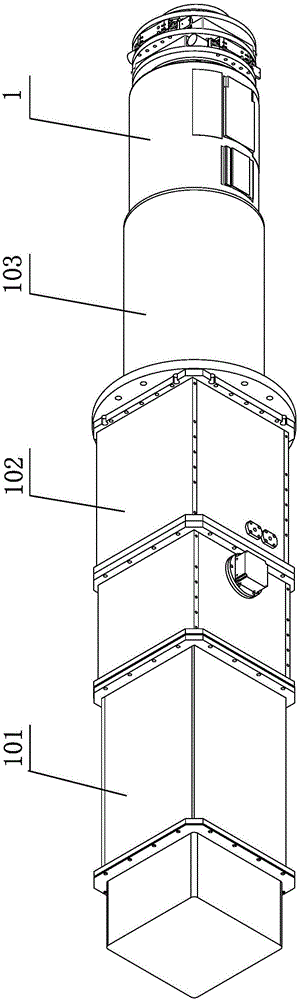

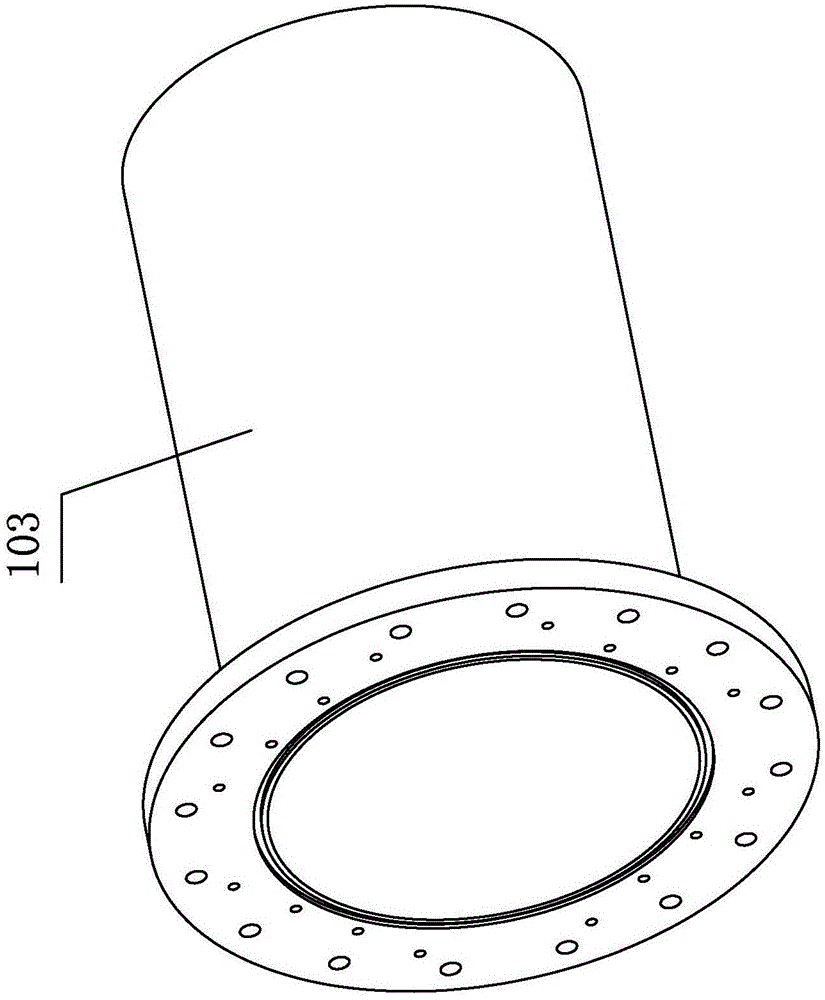

[0016] Specific implementation mode one: combine Figure 1-Figure 22 To illustrate, a large-diameter crystal frequency doubling conversion device for realizing frequency conversion and beam focusing in this embodiment includes a frequency doubling conversion module 101, a frequency doubling conversion module 102, a frequency doubling lens transition piece 103 and a focusing lens 1 ;

[0017] The double frequency conversion module 101 includes a double frequency angle adjustment mechanism 104, and the double frequency angle adjustment mechanism 104 includes a double frequency supine drive assembly 805 and a double frequency yaw drive assembly 801;

[0018] The quadruple frequency conversion module 102 includes a quadruple frequency angle adjustment mechanism 504, and the quadruple frequency angle adjustment mechanism 504 includes a quadruple frequency pitch drive assembly 705 and a quadruple frequency swing drive assembly 701;

[0019] The frequency doubling conversion module ...

specific Embodiment approach 2

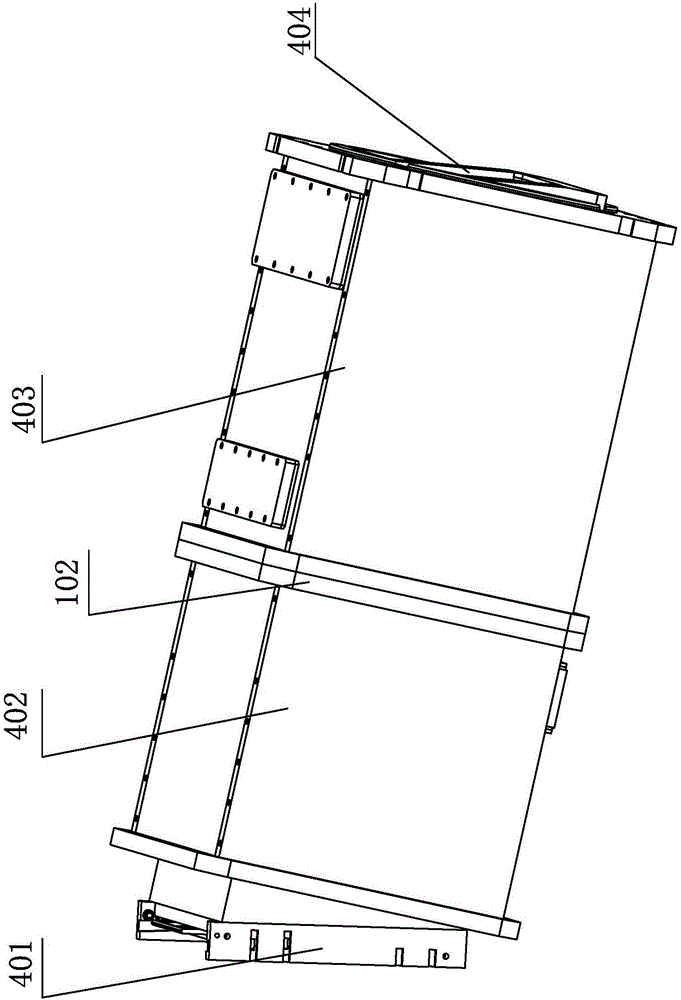

[0023] Specific implementation mode two: combination Figure 5 Explain that the quadruple frequency target window guide assembly 404 of this embodiment includes a vacuum window glass assembly 602, a lens roller 605, a quadruple frequency window frame 603 and two quadruple frequency target chamber vacuum window guide plates 601; Between the vacuum window guide plates 601 of the frequency doubling target chamber, there is a quadruple frequency window frame 603 arranged obliquely. The vacuum window glass assembly 602 is installed in the quadruple frequency window frame 603. Lens rollers 605 are installed, and roller grooves 6011 are provided on the opposite sides of the vacuum window guide plates 601 of the two quadruple frequency target chambers. The lens rollers 605 are arranged in the roller grooves 6011 and can roll up and down in the lens roller grooves 6011. The double frequency window frame 603 is packaged on the flange 506 of the first temperature control box 403 . The v...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 6-Figure 9 Note that the quadruple frequency angle adjustment mechanism 504 of this embodiment also includes a first frame body 704, a second frame body 706, a third frame body 707, a frequency quadruple inner frame 708, and a frequency quadruple crystal assembly 11-7. The first frame body 704, the second frame body 706 and the third frame body 707 are sequentially connected along the direction of light emission, and the second frame body 706 is provided with a yaw rotation connection pair connected with the first frame body 704 in the horizontal direction. The micro-drive mechanism 701 passes through the first frame body 704 and is connected to the upper or lower part of the second frame body 706. The yaw micro-drive mechanism 701 realizes the vertical swing of the second frame body 706 through the yaw-rotation connection pair. The inner frame 708 Installed in the second frame body 706, the inner frame 708 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com