ABS four-wheel loading method and ABS four-wheel loading practical training device

A training device and ABS system technology, applied in the field of ABS four-wheel loading method and training device, can solve the problems of not being able to better test ABS performance, large difference, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the invention is further described:

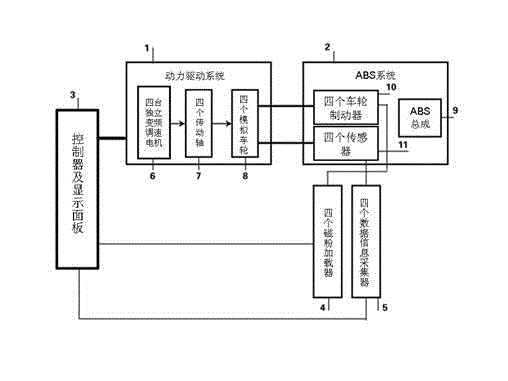

[0016] As shown in the figure: 1. Power drive system, 2. ABS system, 3. Controller and display panel, 4. Four magnetic powder loaders, 5. Four data information collectors, 6. Four independent frequency conversion speed regulation Motor, 7. Four transmission shafts, 8. Four simulated wheels, 9. ABS assembly, 10. Four wheel brakes, 11. Four sensors.

[0017] Install the power drive system and the ABS system on the movable platform, the power drive system includes a frequency conversion speed regulation motor, a transmission shaft and four wheels, the frequency conversion speed regulation motors are four, and four independent frequency conversion speed regulation motors The motors are respectively used as power sources to transmit the power to the transmission shaft through the transmission belt to drive the wheels to rotate. It also includes controller and display...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com