Inverter DC spot welding dynamic resistance real-time measurement device and measurement method

A technology of inverting DC and dynamic resistance, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of incompatibility between the accuracy and implementation of the dynamic resistance measurement technology of inverter DC spot welding, etc. Achieve the effect of improving installation implementation, improving real-time, accurate and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

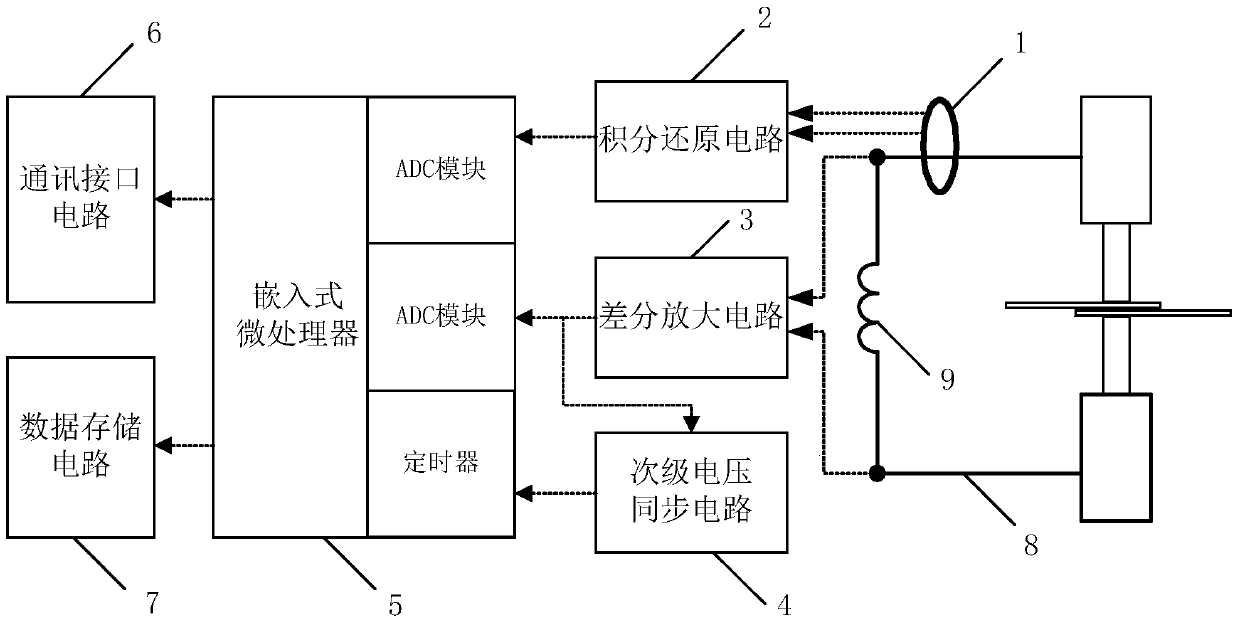

[0024] Specific implementation mode one: see figure 1 Describe the present embodiment, the real-time measuring device of the dynamic resistance of the inverter direct current spot welding described in the present embodiment, it comprises Rogowski coil 1, integral reduction circuit 2, differential amplifier circuit 3, secondary voltage synchronous circuit 4 and embedded microprocessor 5 ;

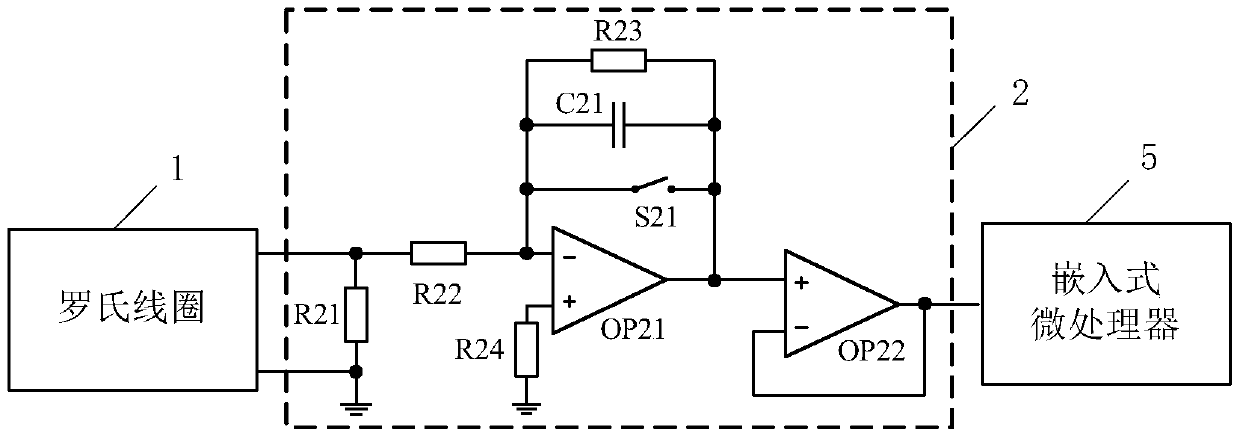

[0025] The Rogowski coil 1 is set on the secondary circuit 8 of the inverter DC spot welding machine, and the two signal output terminals of the Rogowski coil 1 are respectively connected to the two signal input terminals of the integral restoration circuit 2, and the voltage signal of the integral restoration circuit 2 The output terminal is connected to the first analog signal input terminal of the embedded microprocessor 5,

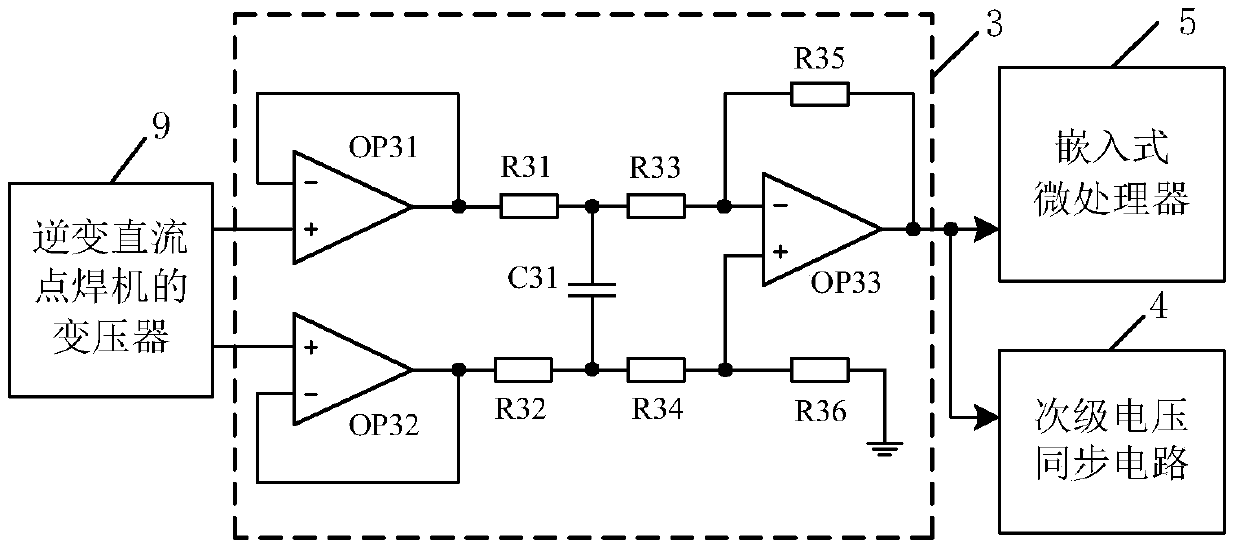

[0026] The two voltage signal input terminals of the differential amplifier circuit 3 are respectively connected to the two ends of the secondary tap of the transfo...

specific Embodiment approach 2

[0029] Specific implementation mode two: see figure 1 Describe this embodiment, the difference between this embodiment and the inverter DC spot welding dynamic resistance real-time measuring device described in the first embodiment is that it also includes a communication interface circuit 6, the data signal input terminal of the communication interface circuit 6 and the embedded micro The first data signal output end of the processor 5 is connected.

[0030] In this embodiment, the communication interface circuit 6 is used for data interaction between the device described in the present invention and other devices.

specific Embodiment approach 3

[0031] Specific implementation mode three: see figure 1 Describe this embodiment, the difference between this embodiment and the inverter DC spot welding dynamic resistance real-time measuring device described in the first embodiment is that it also includes a data storage circuit 7, the data signal input terminal of the data storage circuit 7 and the embedded micro The second data signal output end of the processor 5 is connected.

[0032] In this embodiment, the data storage circuit 7 is used for local recording of measurement data such as current and voltage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com