Multifunctional ultrasonic phased array pipeline circumferential weld detection equipment

A technology of ultrasonic phased array and testing equipment, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the problems that the testing equipment cannot be effectively fixed and achieve convenience effect of moving and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

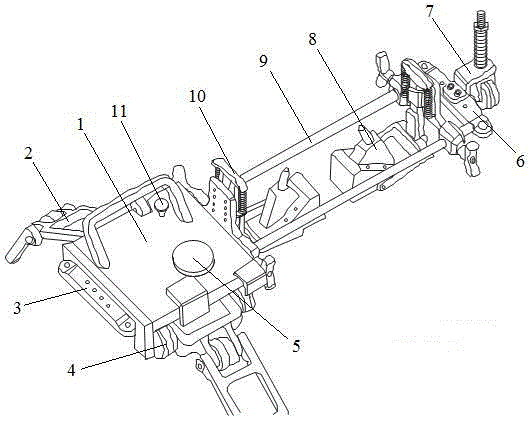

[0065] As shown in the accompanying drawings, a pipeline girth weld testing device of this patent is used to detect flaws in the pipeline girth weld with an acoustic wave flaw detection instrument equipped with a flaw detection probe 8, including a main body, a fastening device 2, and left and right flaw detection probe brackets 10 and left and right flaw detection probes 8 .

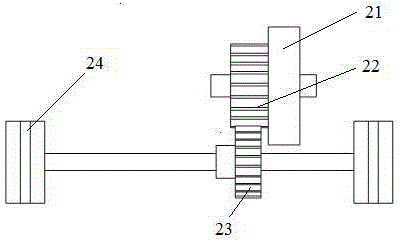

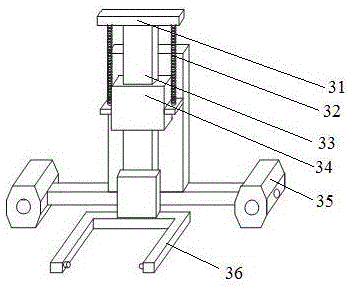

[0066] The main body includes a base 1, a first slide bar, a second slide bar, a slide bar top wire 11, a left and right slide bar coupling frame 35, a magnetic wheel 4 and a wheel shaft; the base 1 is hollow inside, and the side of the base 1 is provided with There are a first slide hole and a second slide hole parallel to each other; the first slide rod is set in the first slide hole; One slide hole and / or the second slide hole are provided with a top wire hole connected with the slide hole, and a slide rod top wire 11 is provided in the top wire hole for tightening the slide rod 9; Both are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com