Fiber-reinforced-plastic composite material R region ultrasonic inspection model establishing method

A fiber-reinforced resin, composite material technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, complex mathematical operations, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be further described by taking the carbon fiber reinforced resin matrix composite material R zone as an example in conjunction with the accompanying drawings.

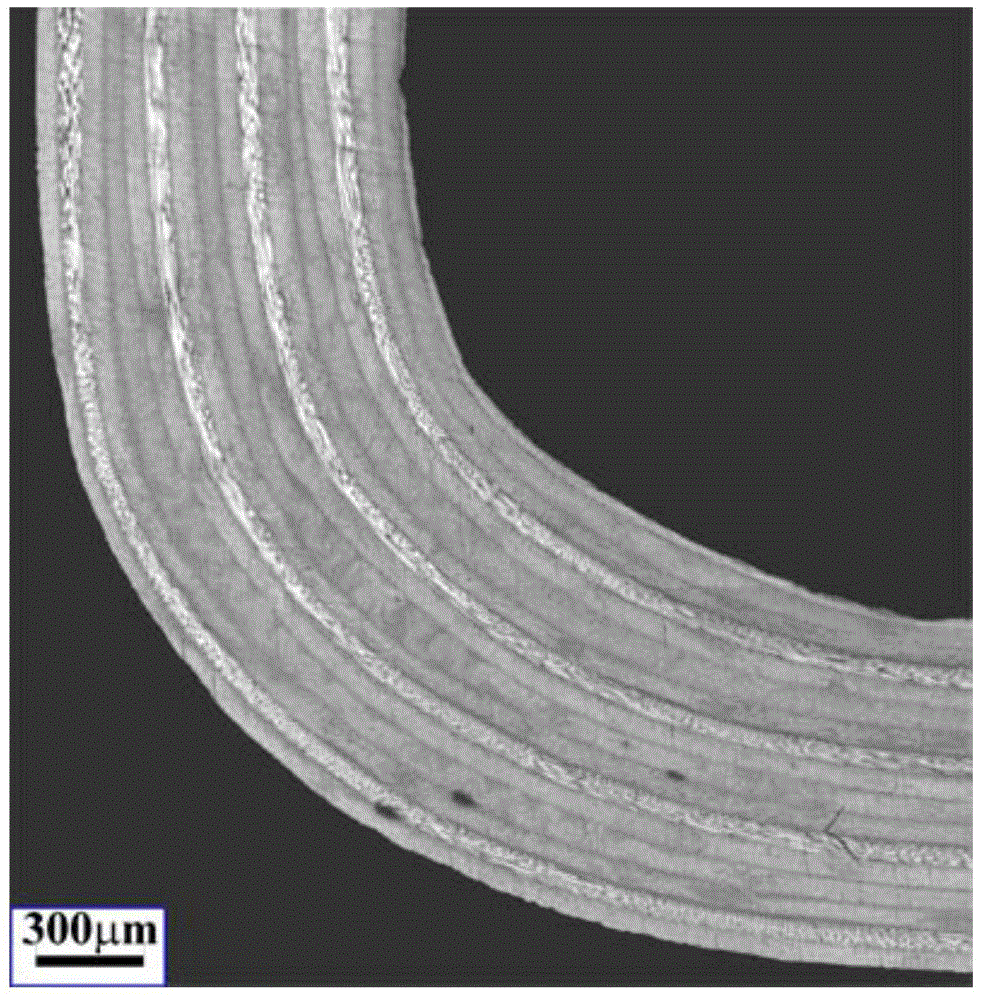

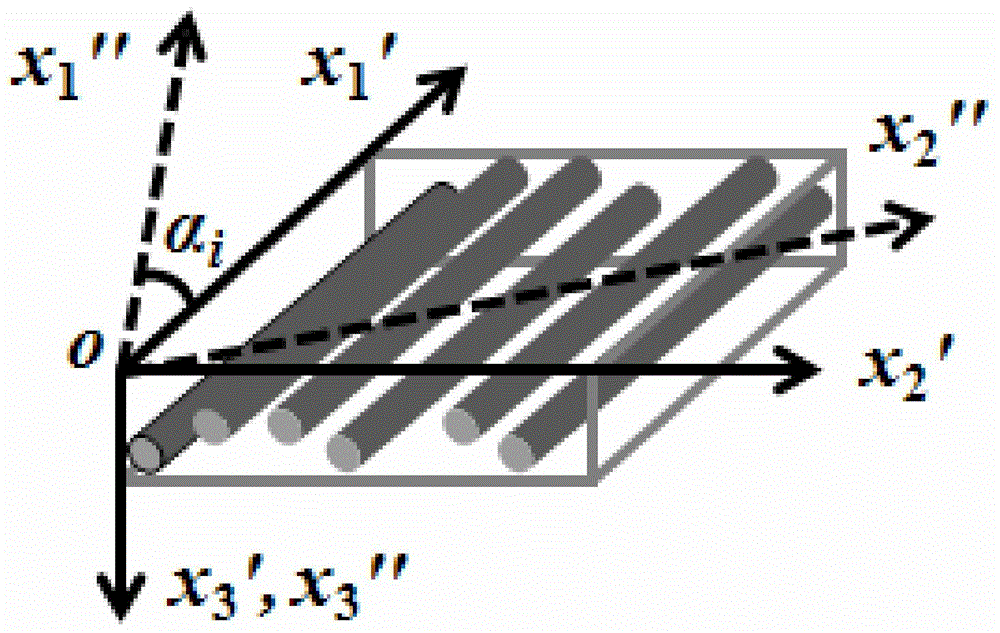

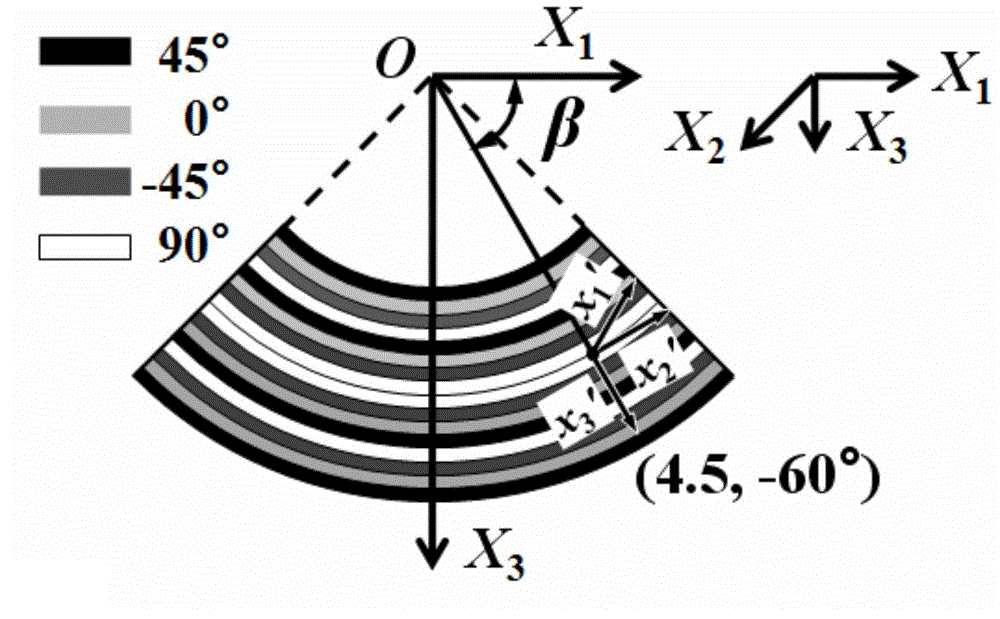

[0031] (1) Using a vernier caliper to measure the thickness of the sample in the R zone of the CFRP composite material is 3.04mm, and using a radius gauge to measure the radius of curvature inside the R zone as R 0 =3.0mm, central angle θ=90°, axial length 10.0mm; the density of the sample measured by the Archimedes drainage method ρ=1.54g / cm 3 ; Dissect the sample along the plane perpendicular to the axis of the R zone, then grind and polish the section, and conduct metallographic observation and measurement. figure 1 It is the metallographic photo of the cross-section of the sample in the R zone of the CFRP composite material: the thickness of the single layer t = 0.190mm, the total number of layers N = 16, the order of fiber laying i =[45 / 0 / -45 / 90] 2S (wherein, i=1, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com