Device and method for 360-degree bottle body production line backlight vision inspection

A visual inspection device and assembly line technology, applied in the direction of optical testing flaws/defects, can solve the problems of low space utilization, unsatisfactory, loose structure, etc., and achieve the effect of improving space utilization, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

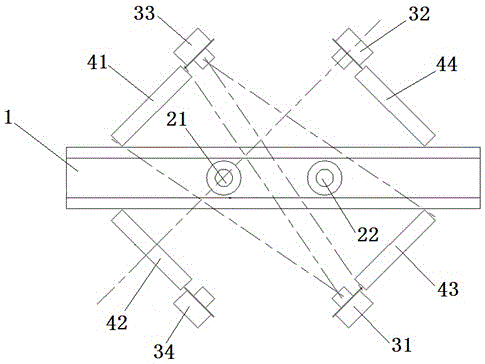

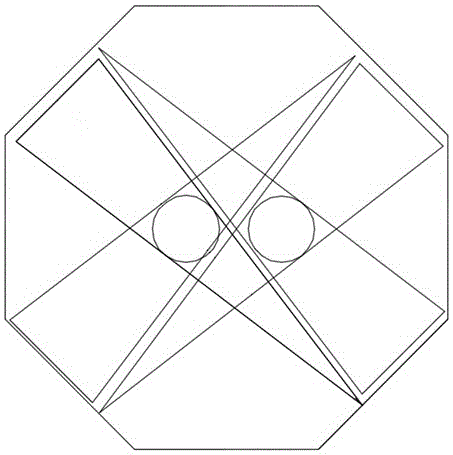

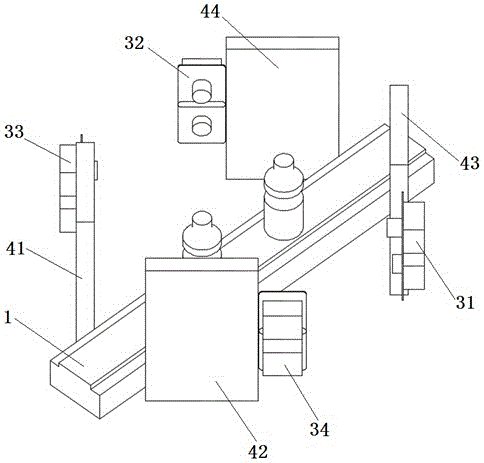

[0024] like figure 1 As shown, a 360-degree bottle body assembly line backlight visual inspection device includes a first inspection station 21 and a second inspection station 22 arranged on the assembly line conveyor belt 1 and first inspection stations symmetrically distributed on both sides of the assembly line conveyor belt 1. Group industrial camera 31, second group industrial camera 32, third group industrial camera 33, fourth group industrial camera 34, first group planar light source 41, second group planar light source 42, third group planar light source 43 and fourth group Planar light source 44 .

[0025] The first group of industrial cameras 31 and the third group of planar light sources 43 are arranged in close proximity to form the first abutting unit, and the second group of industrial cameras 32 and the fourth group of planar l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com