Measuring Method of Cannon Pitching Radius

A technology of radius measurement and artillery, applied in the field of measurement, can solve the problems of difficult to implement direct measurement and not provided, and achieve the effect of satisfactory measurement accuracy, convenient operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

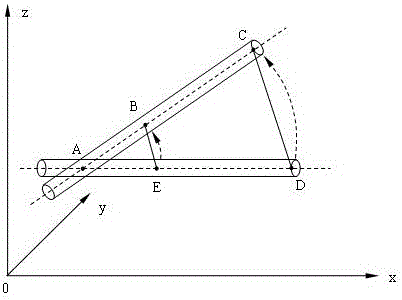

[0033] Concrete operation steps of the present invention are:

[0034] (1) The artillery to be tested drives into the designated detection area, and the artillery is adjusted vertically and horizontally with a jack, so that the barrel of the artillery is in a horizontal position;

[0035] (2) Accurately paste the crosshairs on the end face of the muzzle, so that the center of the crosshairs represents the center of the muzzle, and the firing pin is removed from the breech to reveal the firing pin hole;

[0036] (3) Set up the theodolite directly in front of the artillery, and turn the artillery direction machine and the height machine so that the optical axis of the theodolite coincides with the center of the muzzle cross and the center of the firing pin hole;

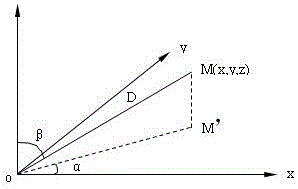

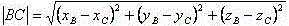

[0037] (4) Turn the gun direction machine until the side of the barrel can be observed in the theodolite, paste two cross marks on the busbar on the side of the barrel, and use the optical axis of theodolite to adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com