Drive axle self-locking differential

A differential and drive axle technology, which is applied in the field of drive axle self-locking differentials, can solve the problems of high power consumption, etc., and achieve the effects of prolonging service life, sensitive locking speed, and improving driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

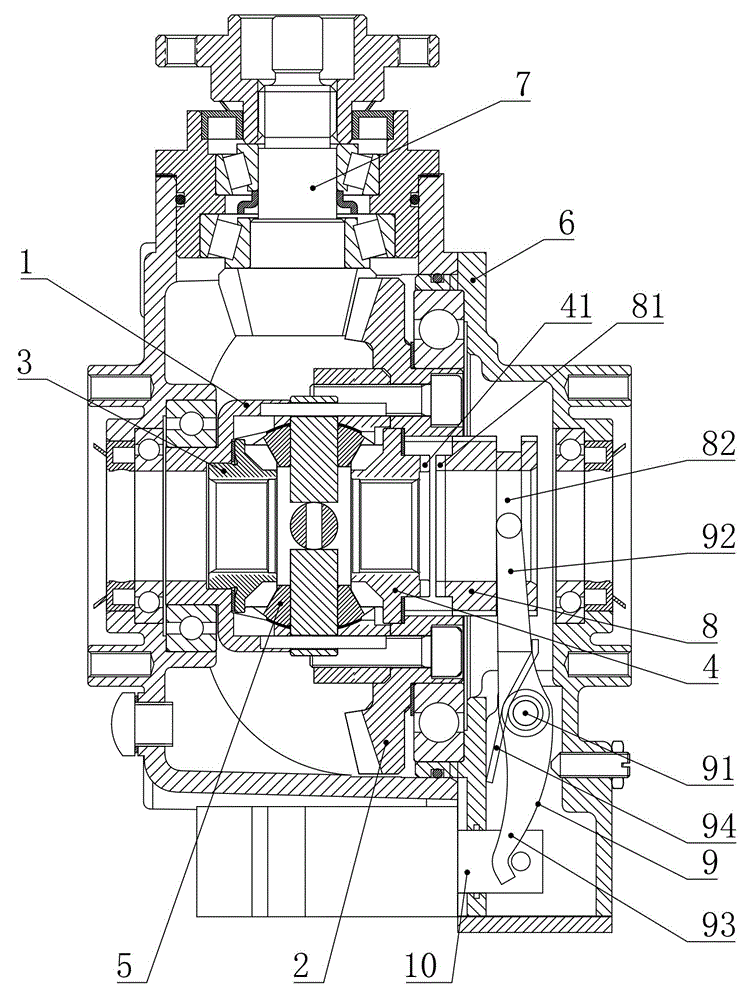

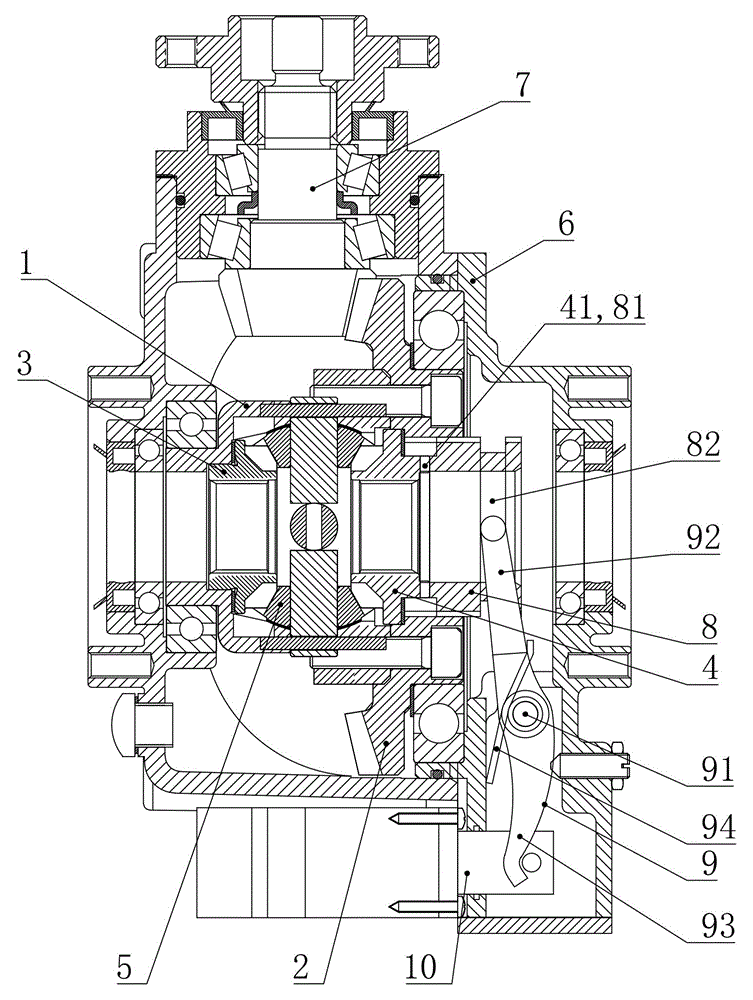

[0028] Such as figure 1 As shown, the transaxle self-locking differential of this embodiment includes a differential case 1 , a transmission gear 2 , a left side gear 3 , a right side gear 4 and a planetary gear 5 . The differential case 1 is rotatably supported in the drive axle case 6, and the transmission gear 2 is a large arc tooth, which is fixedly connected to the differential case 1, and is connected with the input shaft installed in the drive axle case 6. Gear shaft 7 transmission connection. The left side gear 3, the right side gear 4 and the planetary gear 5 are all located in the differential housing 1, wherein the left and right side gears 3, 4 are coaxially arranged with the transmission gear 2, and the planetary gear 5 is respectively connected to the left , Right side shaft gears 3 and 4 mesh simultaneously.

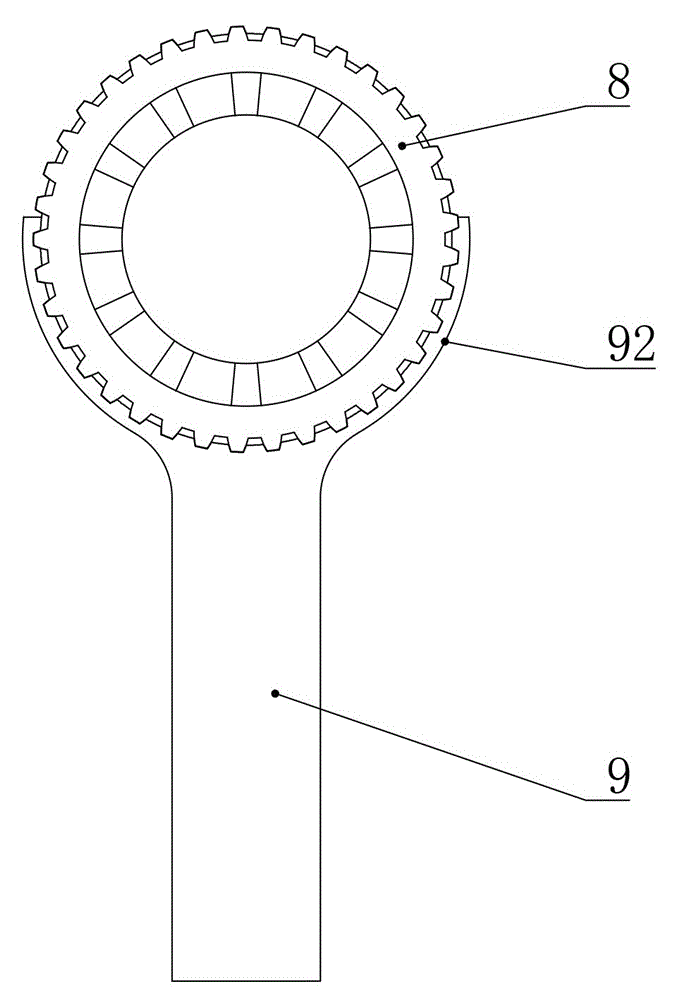

[0029] The right side of the right side gear 4 is coaxially provided with a locking movable sleeve 8, the locking movable sleeve 8 is located in the dif...

Embodiment 2)

[0034] This embodiment is basically the same as Embodiment 1, except that in this embodiment, the right side gear has an extension extending axially to the right, and the circumferential limiting structure includes The first spline and the second spline are located on the inner peripheral surface of the locking movable sleeve, and the first spline and the second spline are arranged in cooperation. When the locking movable sleeve moves to the left, the second spline gradually meshes with the first spline, so that the right side shaft gear is combined with the differential case to realize locking.

Embodiment 3)

[0036] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the right side gear has an extension extending axially to the right and deep into the locking movable sleeve, and the locking movable sleeve passes through the flower The key connection is fixed circumferentially with the extension, and a circumferential limiting structure is provided between the locking movable sleeve and the differential case. The circumferential limiting structure includes end teeth three on the right end surface of the differential housing and end teeth four on the left end surface of the locking movable sleeve, and the end teeth three and end teeth four are arranged in cooperation. When the locking movable sleeve moves to the left, the fourth end tooth gradually meshes with the third end tooth, so that the right side shaft gear is combined with the differential case to realize locking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com