Supporting method of strip mining with large mining height and roadway filling

A technology of filling strips and large mining height, which is applied in surface mining, mining equipment, earth-moving drilling, etc., can solve problems such as failure to timely and effectively control the subsidence of the roadway roof, threatening the safe use of the surface, and aggravating the deformation and damage of the surface. To achieve the effect of good control of surface movement and deformation, good social and economic benefits, and ensure safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Divide the coal seam area to be mined into strip shapes, determine several mining strips and several reserved strips, and arrange the mining strips and reserved strips sequentially;

[0048] In this embodiment, the net width of the mining strip mining face is 4000 mm, and the net height is 2500 mm. After the excavation is in place, the blasting will reach the bottom to a height of 5000 mm.

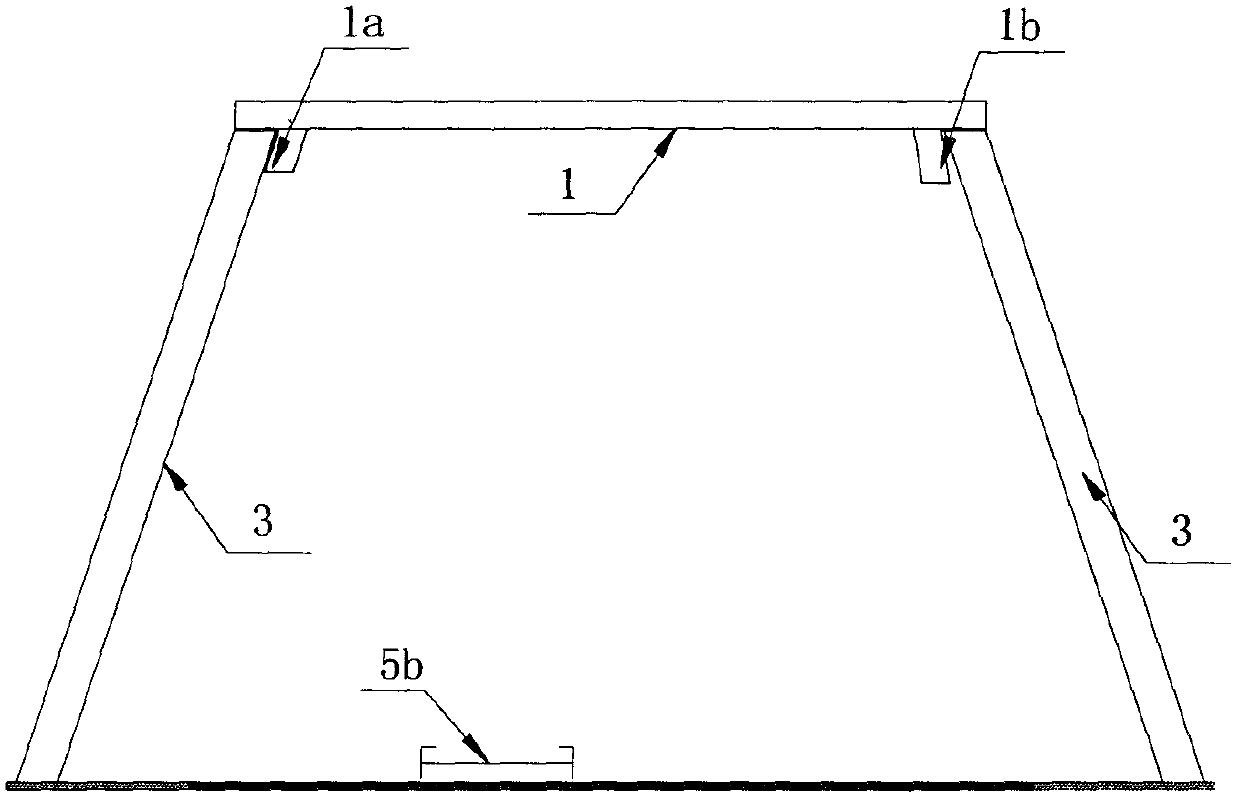

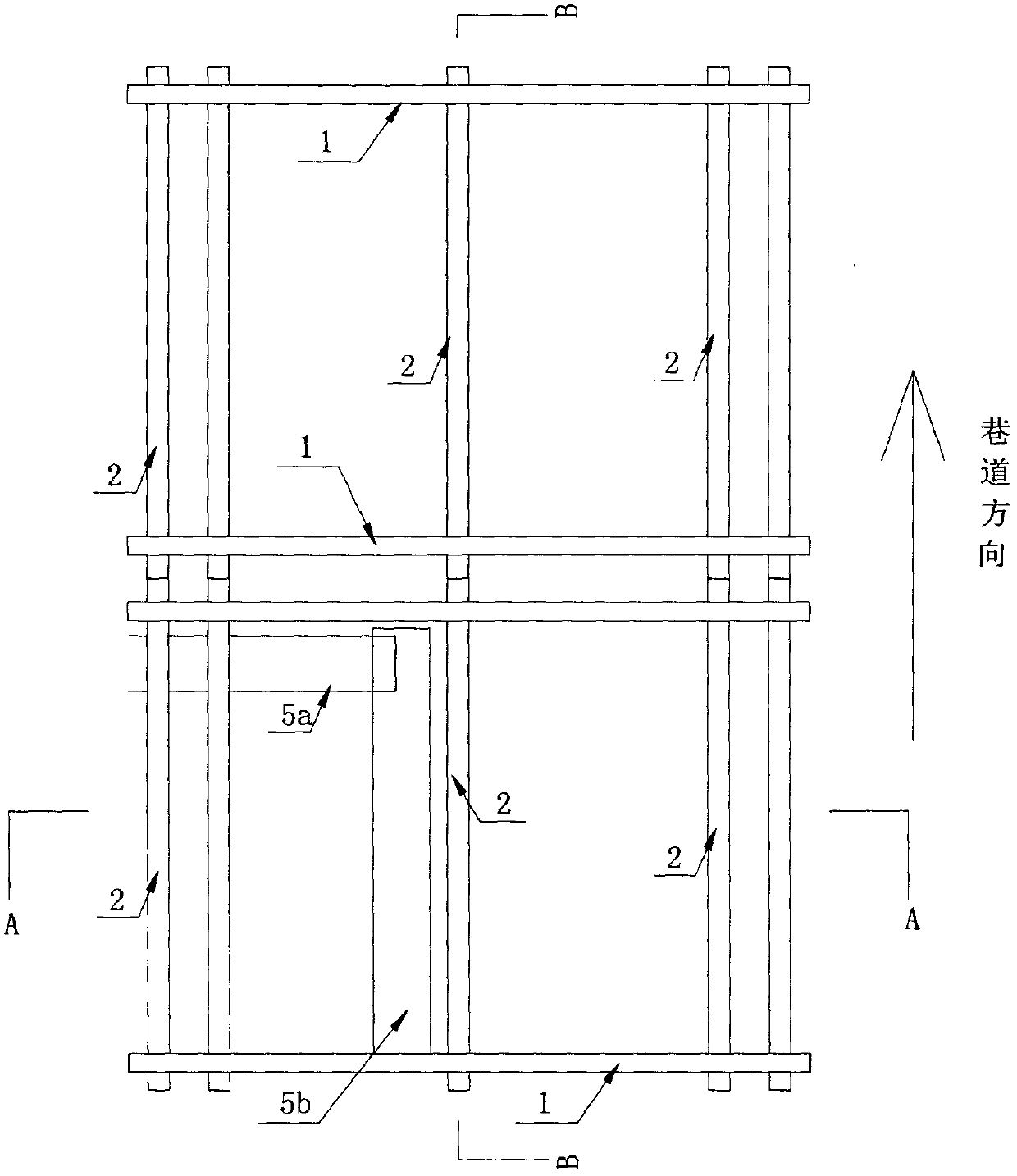

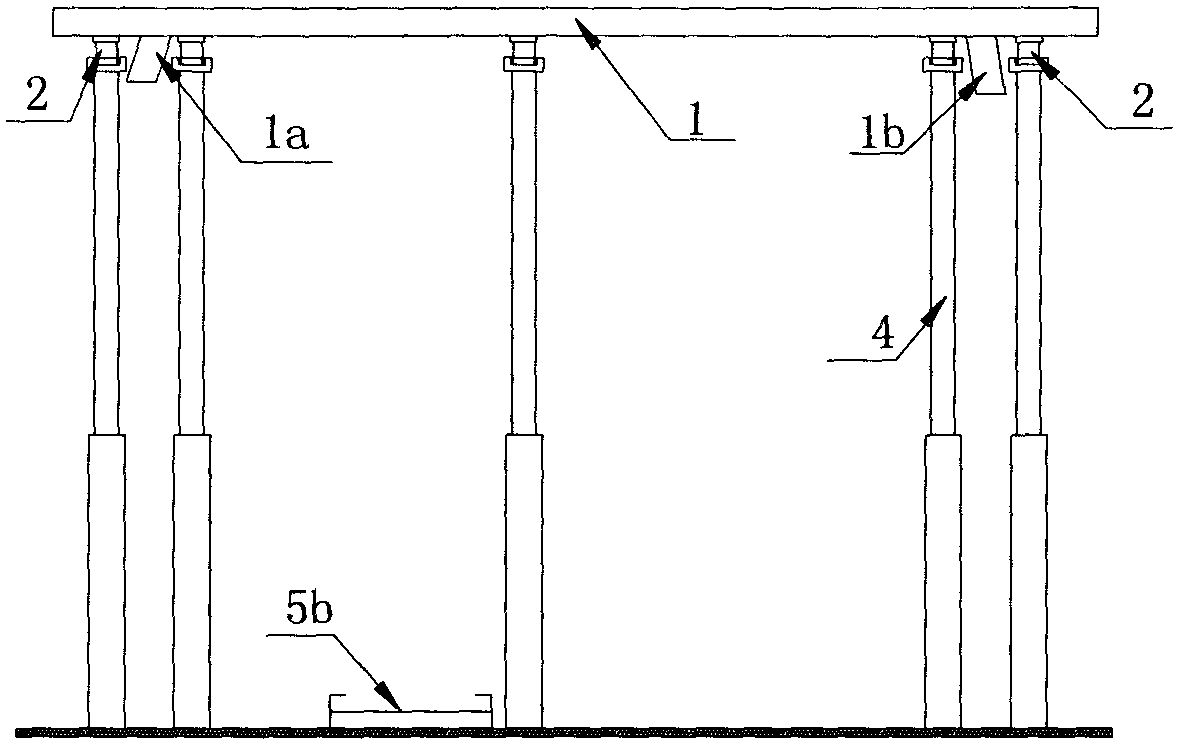

[0049] Such as figure 1 , 2 As shown in , 3 and 4, before the strip opening is mined, the industrial steel shed within the range of no less than 5m before and after the opening is maintained by cutting the sub-shed.

[0050] Such as figure 1 As shown, the industrial steel shed is set up. The industrial steel shed includes two industrial steel columns 3 arranged longitudinally along the roadway and an industrial steel roof beam 1 horizontally installed on the industrial steel column. The beam claws 1a, 1b, and the I-steel column 3 are tilted against the lower part of the I-steel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com