Pushing type double-wheel concrete vibrator

A vibrator, concrete technology, applied in the direction of construction, building construction, building materials processing, etc., can solve the problems of uneven concrete surface, low vibration efficiency, and vibrator sinking, etc.

Inactive Publication Date: 2015-12-16

肖栋

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The present invention mainly adopts two kinds of vibration technologies for the currently used small-scale concrete vibration equipment, one uses a vibrating rod, which adopts insertion vibration, and the main defect of insertion vibration is that the vibration efficiency is too low to meet people's use requirements

The other is planar vibration. Compared with the insertion type vibration, the effect of planar vibration is better and the efficiency is higher. However, there is still a big defect in the planar vibrator currently used, that is, the stability is poor and it is not easy to Operation, because the concrete is relatively loose, it is easy to sink the whole vibrator, resulting in stacking of the concrete work surface around the vibrating plate, making the concrete surface uneven and uneven, and it is not easy to operate, requiring the cooperation of multiple people to operate, which is very inconvenient to use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

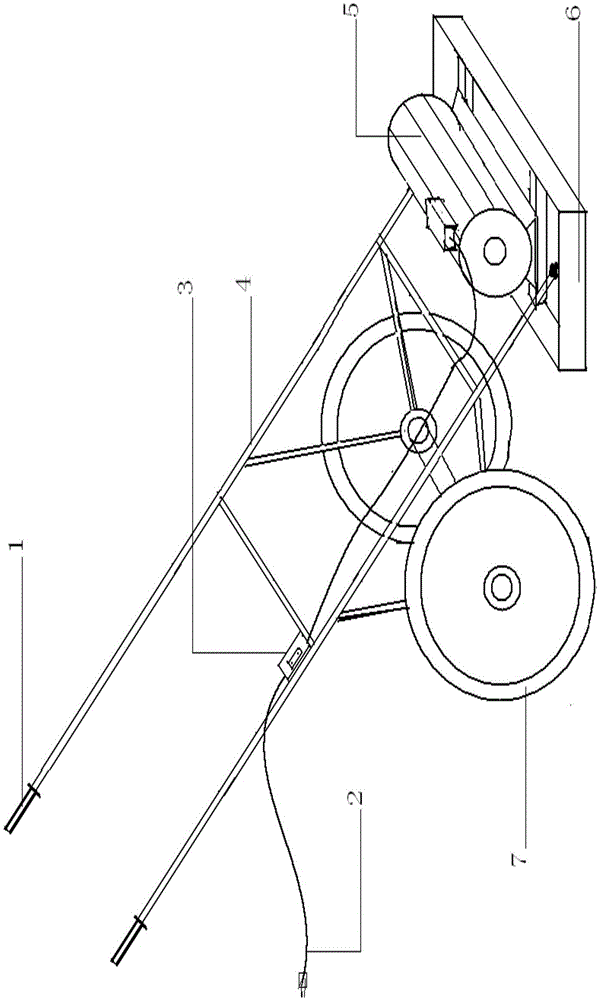

[0009] As shown in the figure; the vibrator 5 is installed on the vibrator vibration plate 6, the vibrator vibration plate 6 is connected with the main frame 4, the rear end of the main frame 4 is provided with an operating handle 1, and the main frame 4 is equipped with a power switch 4, the power supply The power connection line 2 is connected on the switch 4, and the wheels 7 are installed on the main frame 4.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of building machinery and discloses a pushing type double-wheel concrete vibrator. Two vibration devices in the prior art both have shortcomings; the insertion type vibration device is low in vibration efficiency; the plane vibration device is poor in stability and difficult to operate and easily gets sunken due to the fact that concrete is diluted, then vibration plates are stacked on the concrete work surface, the concrete surface becomes uneven and nonuniform, many persons need to cooperate for operating the plane vibration device, and use is inconvenient. The pushing type double-wheel concrete vibrator is specifically composed of an operating handle, a power connection line, a power switch, a main frame, a vibrator body, a vibrator body vibration plate and wheels. The vibrator body is installed on the vibrator body vibration plate, the vibrator body vibration plate is connected to the main frame, the operating handle is arranged at the rear end of the main frame, the main frame is provided with the power switch, the power connection line is connected to the power switch, and the wheels are installed on the main frame. According to the invention, the shortcomings in the prior art can be overcome.

Description

technical field [0001] The invention relates to the field of construction machinery, and relates to a hand-push double-wheel concrete vibrator. Background technique [0002] The present invention mainly adopts two kinds of vibration technologies for the currently used small-scale concrete vibration equipment, one uses a vibrating rod, which adopts insertion vibration, and the main defect of insertion vibration is that the vibration efficiency is too low to meet people's use requirements . The other is planar vibration. Compared with the insertion type vibration, the effect of planar vibration is better and the efficiency is higher. However, there is still a big defect in the planar vibrator currently used, that is, the stability is poor and it is not easy to Operation, because the concrete is relatively loose, it is easy to sink the whole vibrator, resulting in stacking of the concrete working surface around the vibrating plate, making the concrete surface uneven and uneven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04G21/08

Inventor 不公告发明人

Owner 肖栋

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com