Partition support system for large-area deep foundation pit under forward and backward working condition, and construction method thereof

A support system and deep foundation pit technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems that cannot fully meet the safety requirements of on-site construction and surrounding environment, and reduce the overall exposure time, shorten the flow time, and reduce the length and distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

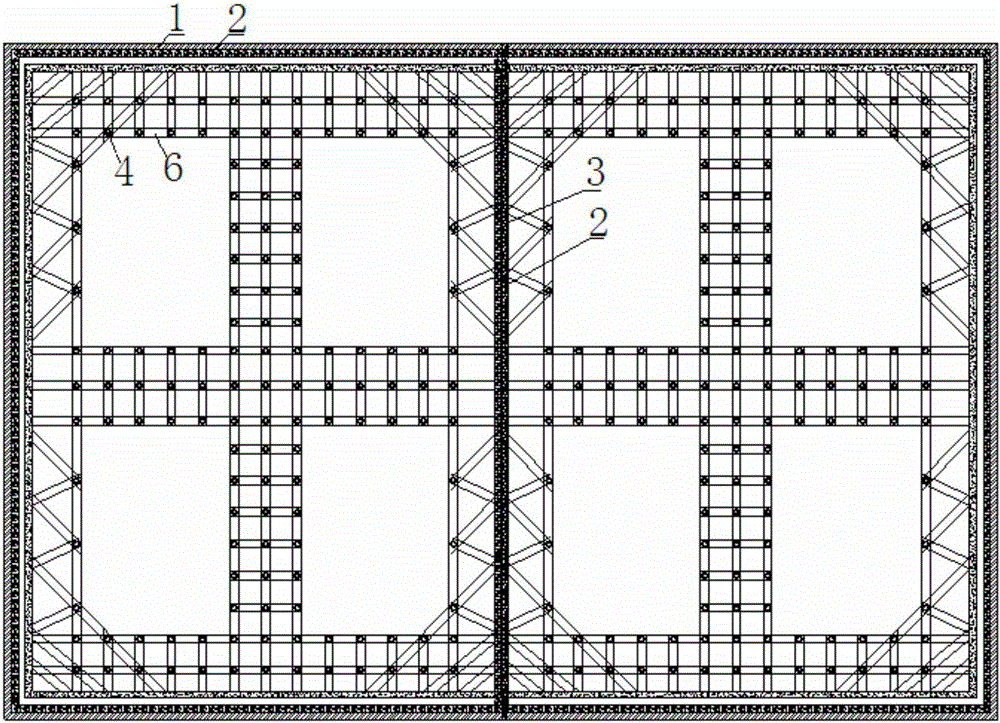

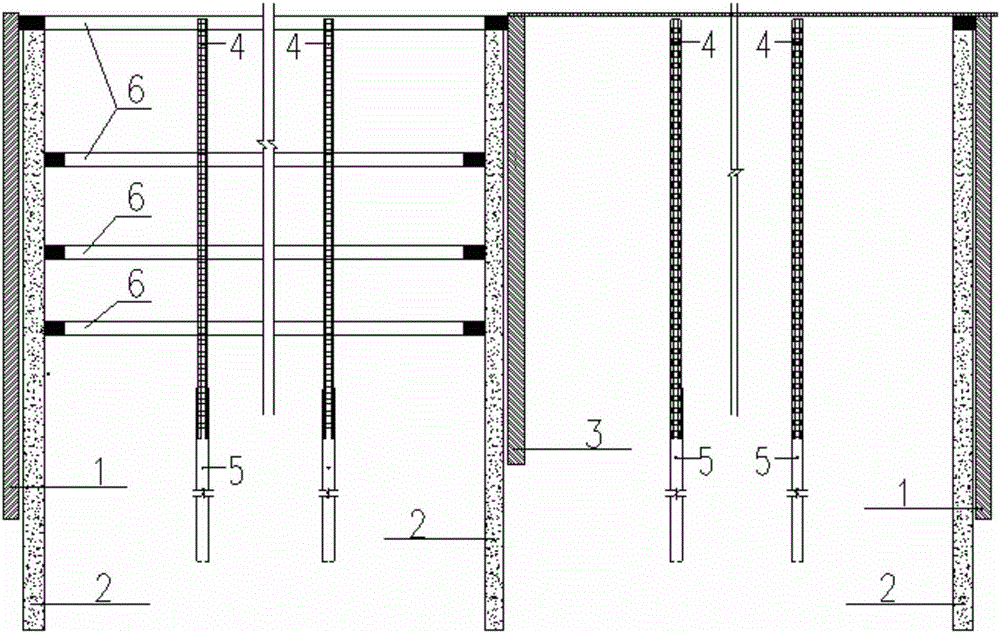

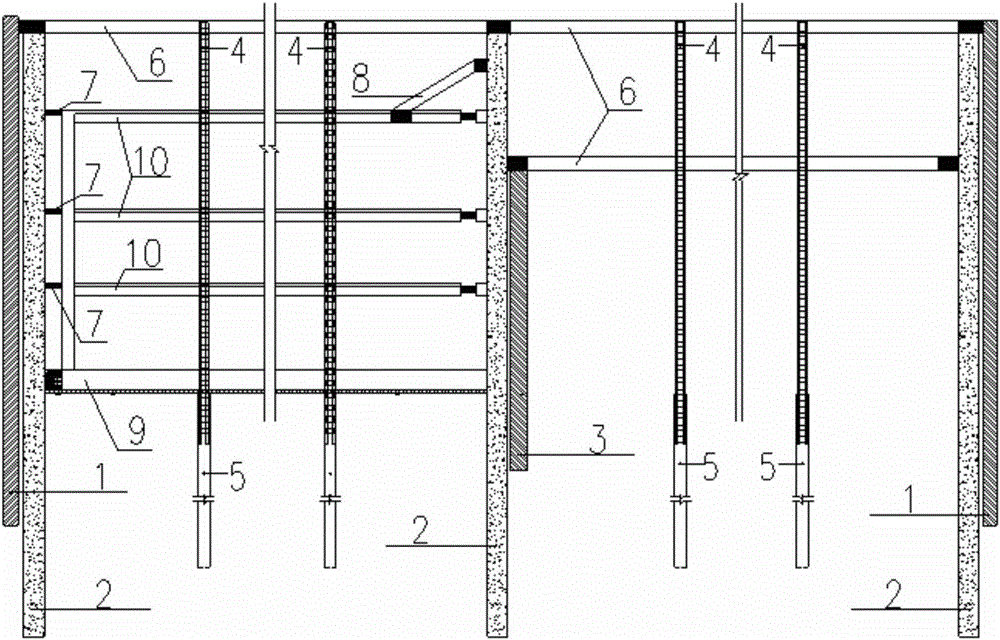

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a support system for a large-area deep foundation pit of the present invention under partitioned forward and reverse working conditions includes a TRD water-stop curtain 1, an enclosure pile 2, a three-axis stirring pile 3, a lattice column 4, a column pile 5, The reinforced concrete inner support 6 is characterized in that: a closed water stop wall on the outside of the deep foundation pit is formed by the TRD water stop curtain 1; a row of retaining piles 2 are arranged on the inner side of the TRD water stop curtain 1 as the support system of the deep foundation pit; A triaxial stirring pile 3 is arranged in the middle of the deep foundation pit to divide the deep foundation pit into two regions, and a row of surrounding piles 2 is arranged on one side of the triaxial stirring pile 3; several column piles 5 are arranged in the deep foundation pit, each The column pile 5 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com