A construction method for mechanical excavation of pre-drilled stonework

A construction method and pre-drilling technology, used in excavation, infrastructure engineering, construction, etc., can solve the problems of slow construction speed, low efficiency, high noise, etc., and achieve the effect of improving construction work efficiency and increasing the scope of applicable rocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

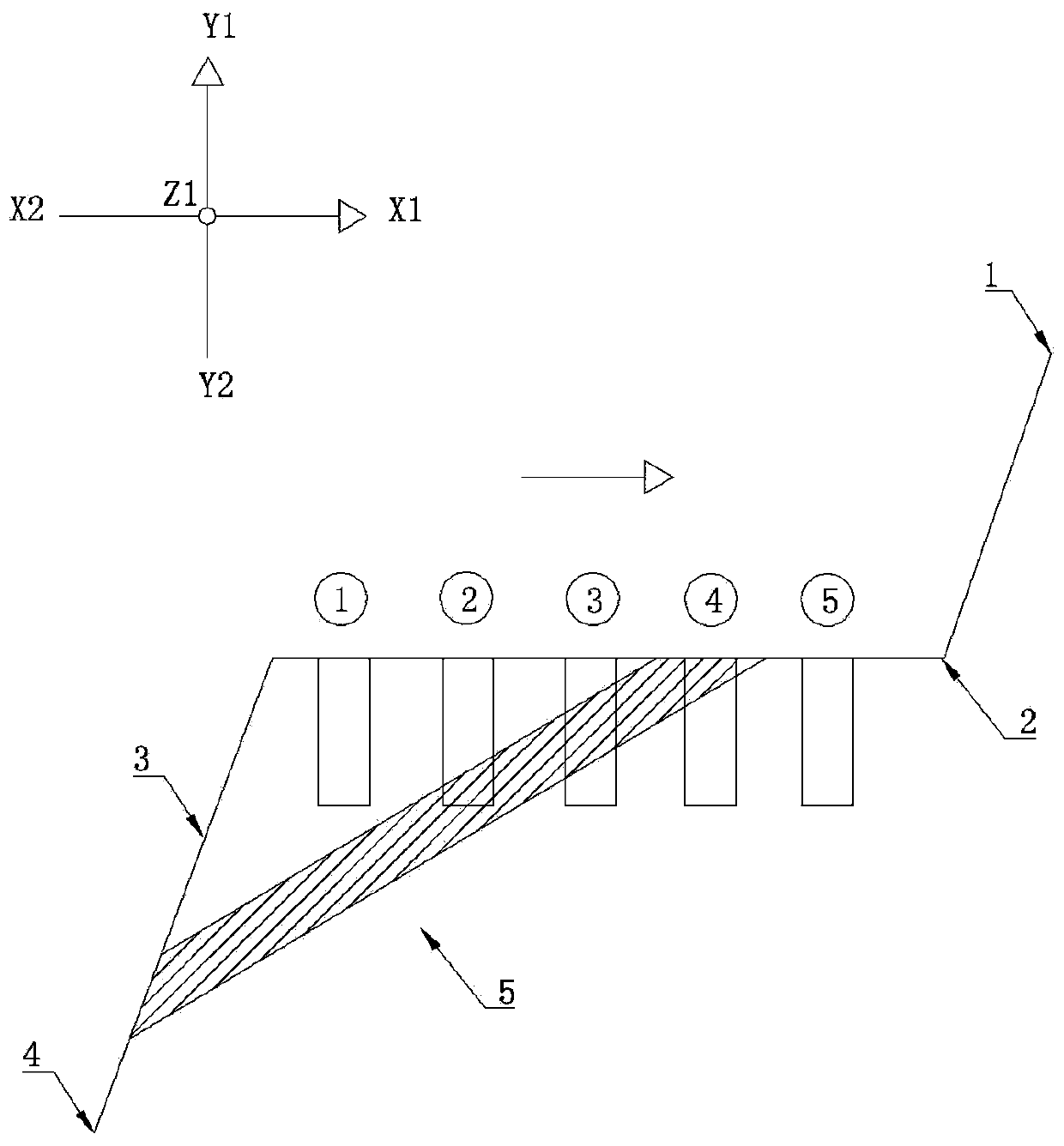

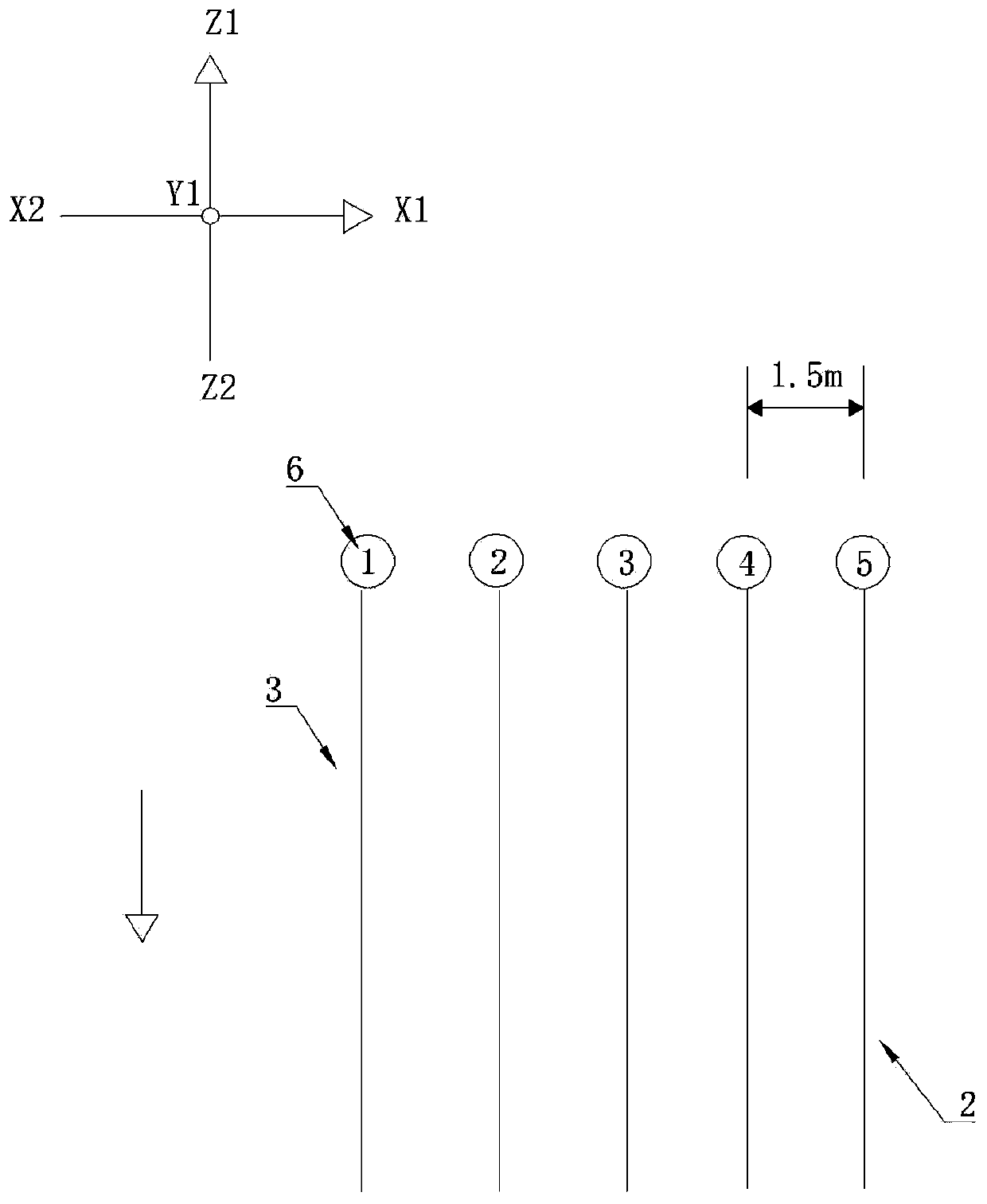

[0037] Such as figure 1 , figure 2 , Figure 5 , Figure 7 As shown, a construction method for pre-drilled stonework mechanical excavation comprises the following steps:

[0038] Step 1, the construction preparation stage, including felling trees, temporary drainage, selection of slag yards, identification of underground pipelines, protection of underground pipelines, excavation of topsoil and strong weathered rocks that can be directly excavated, lithology determination, etc.;

[0039] Step 2, the excavation route planning stage, select a reasonable excavation sequence and operation route according to the difference between the rock mass bedding and inverse bedding, planning follows the first high and then low, first broken and then complete, effective use of the free surface and the direction of the rock strata ;

[0040] Step 3, the plum blossom pre-drilling stage, the down-the-hole drill is used for pre-drilling. The pre-drilling includes two types of stress holes an...

Embodiment 2

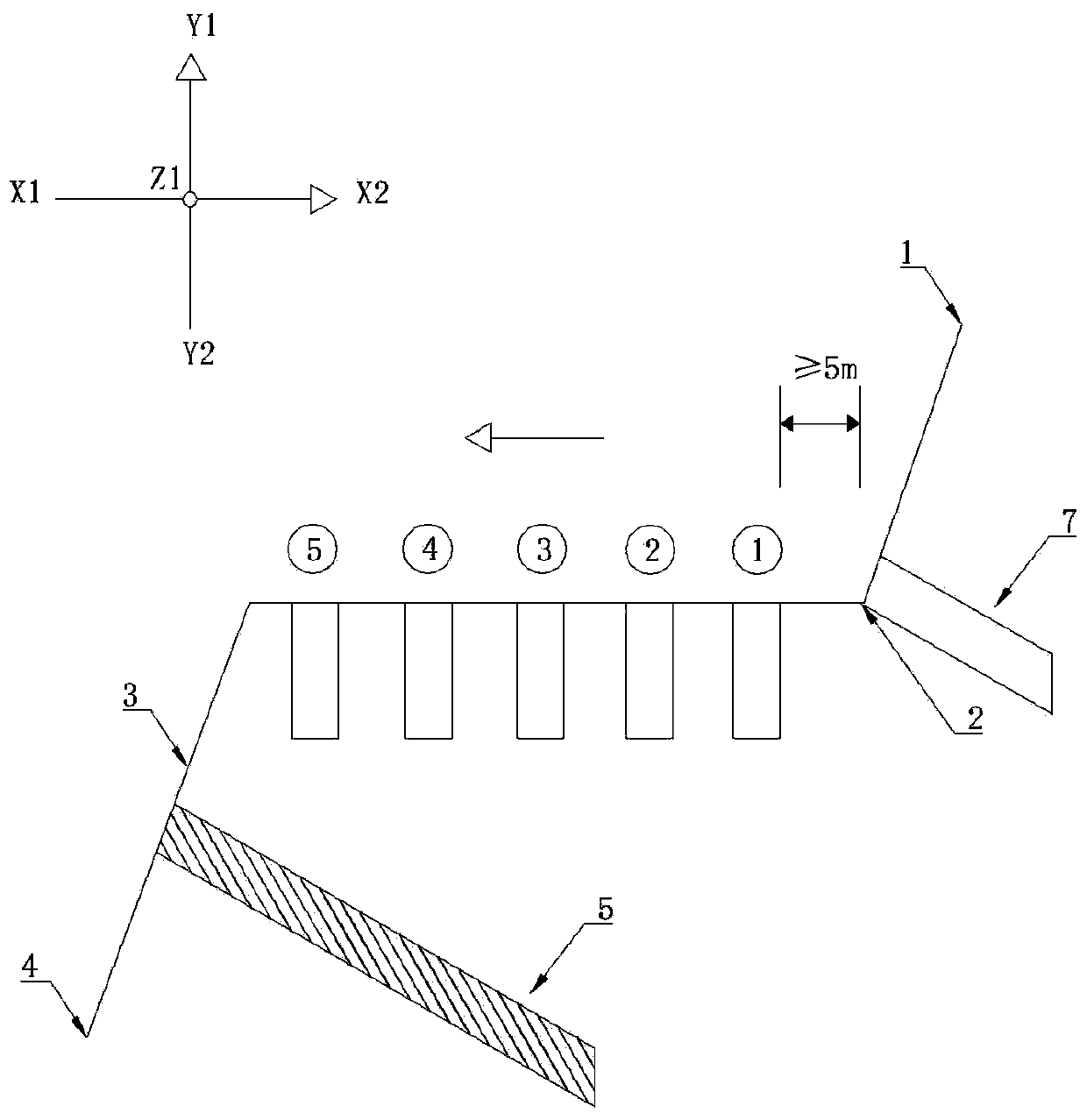

[0071] Such as image 3 , Figure 4 , Figure 6 , Figure 7 As shown, a construction method for pre-drilled stonework mechanical excavation comprises the following steps:

[0072] Step 1, the construction preparation stage, including felling trees, temporary drainage, selection of slag yards, identification of underground pipelines, protection of underground pipelines, excavation of topsoil and strong weathered rocks that can be directly excavated, lithology determination, etc.;

[0073] Step 2, the excavation route planning stage, select a reasonable excavation sequence and operation route according to the difference between the rock mass bedding and inverse bedding, planning follows the first high and then low, first broken and then complete, effective use of the free surface and the direction of the rock strata ;

[0074] Step 3, the plum blossom pre-drilling stage, the down-the-hole drill is used for pre-drilling. The pre-drilling includes two types of stress holes and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com