Rotating rod type gate hoist

A hoist and gate technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as equipment failure or shutdown, increased friction between nuts and screws, and increased wear speed, achieving small resistance and smooth operation. Smooth, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described below in conjunction with embodiment and accompanying drawing.

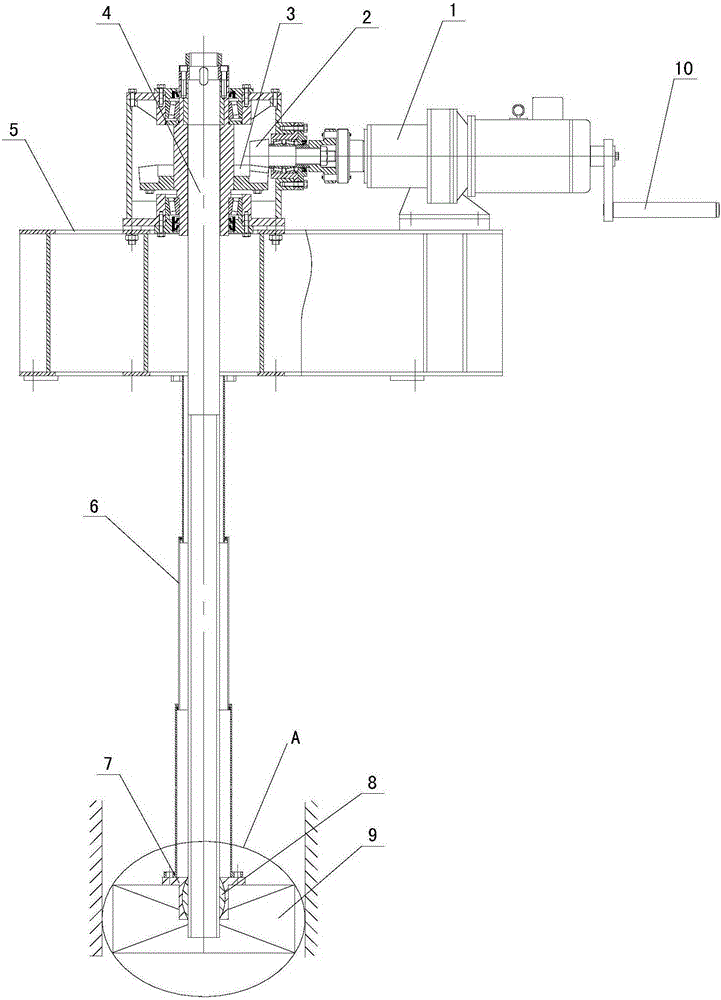

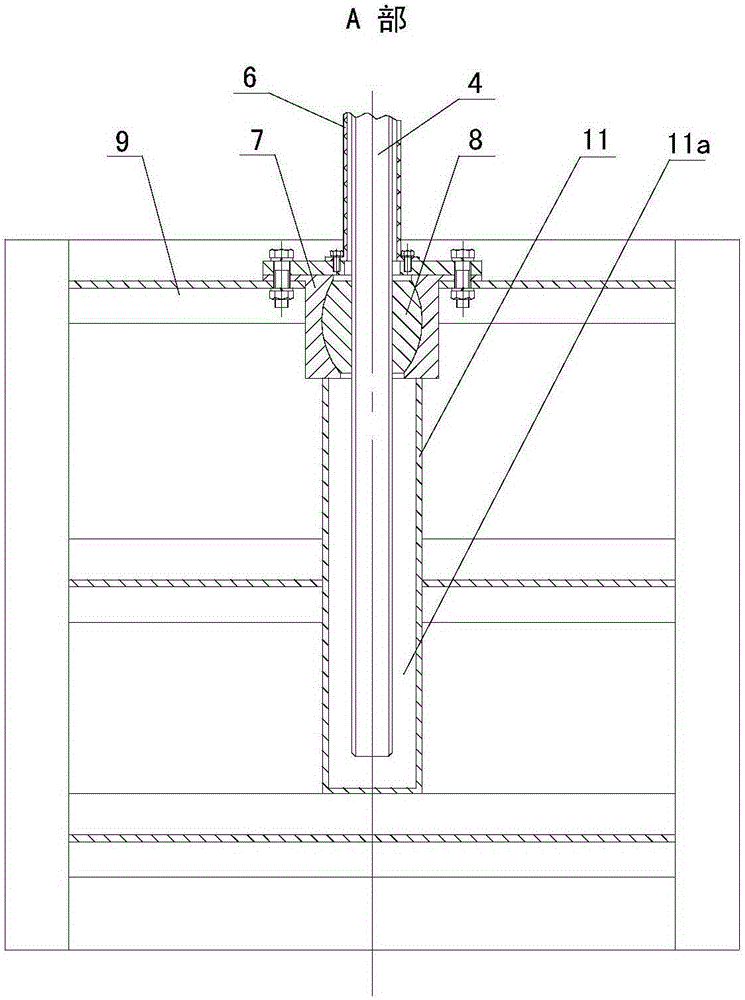

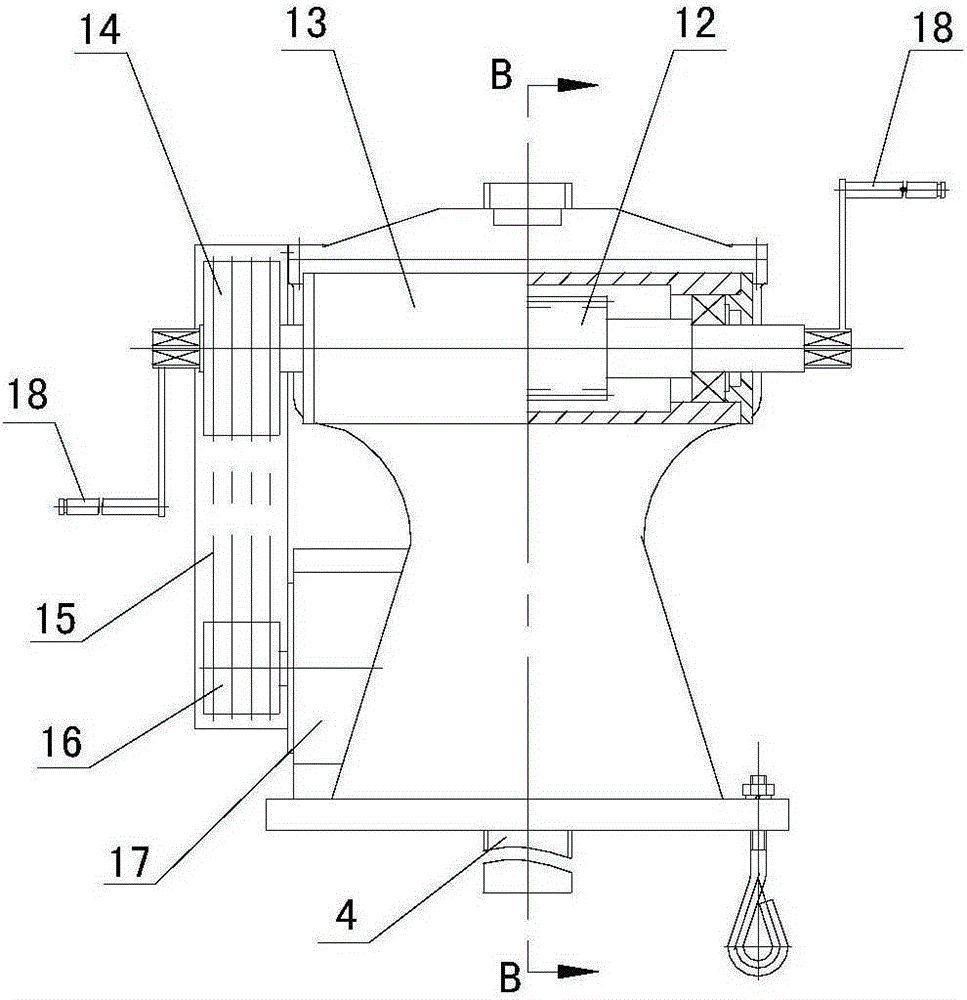

[0012] see figure 1 , figure 2

[0013] The rotary rod type gate hoist provided by the present invention has a motor 1, a frame 5, a screw rod 4 and a gate 9, the screw rod 4 is installed on the frame 5, and a transmission mechanism is connected between the output shaft of the motor 1 and the screw rod 4, and the gate 9 is connected with nut 8, and screw rod 4 cooperates with nut 8. A shaft sleeve 7 is fixed on the gate 9, and a nut 8 is installed in the shaft sleeve 7. The outer surface of the nut 8 and the surface of the inner hole of the shaft sleeve 7 are spherical, and the gap between the outer surface of the nut 8 and the inner hole of the shaft sleeve 7 Cooperate. A multi-section telescopic sleeve pipe 6 is sheathed outside the screw rod 4 , the upper end of the sleeve pipe 6 is connected with the frame 5 , and the lower end of the sleeve pipe is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com