An automatic cleaning and maintenance device with improved service life and used for bridges

An automatic cleaning and maintenance device technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as increased maintenance costs, corrosion, safety and stability risks of bridge structures, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

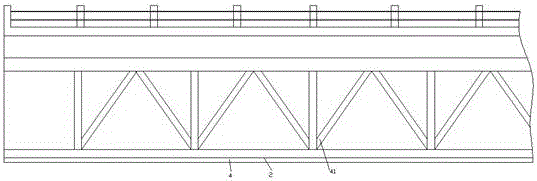

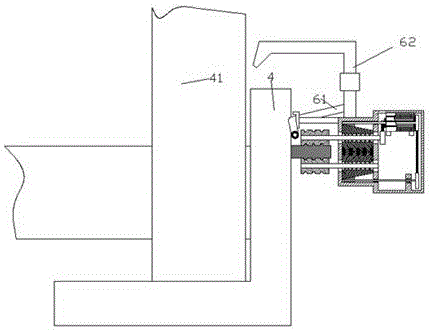

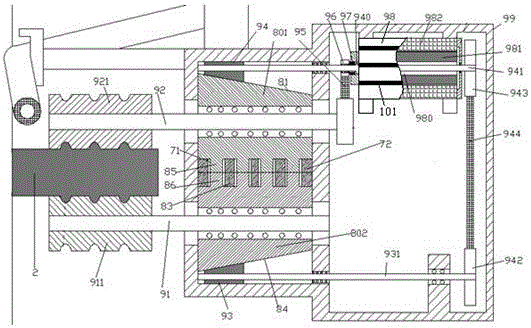

[0011] Combine below Figure 1-4 The present invention will be described in detail.

[0012] According to the embodiment, the service life is improved and the automatic cleaning and maintenance device for bridges, the bridge includes a transverse main beam 4 provided with a transversely extending guide rib 2 and a sub-beam 41 supported on the transverse main beam 4, the automatic cleaning The maintenance device includes a support frame 99, a water supply pipe 61 supported on the support frame 99 and close to the transverse girder 4, and a nozzle 62 communicated with the water supply pipe 61 so as to spray water at the parts of the bridge that need to be cleaned. Cleaning, the upper and lower surfaces of the guide rib 2 are respectively provided with a plurality of guide protrusions extending along the guide rib 2, so as to be able to engage with the upper supports on the upper and lower surfaces of the automatic cleaning and maintenance device respectively The roller 921 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com