Synchronous slow-release humic acid fertilizer produced by using high tower process and production method of synchronous slow-release humic acid fertilizer

A production method and technology of humic acid, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of low fertilizer utilization rate, environmental pollution, waste of resources, etc., and achieve the effects of improving quality, improving soil quality, and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A humic acid synchronous slow-release fertilizer formula produced by a high-tower process: 39 parts of urea, 11 parts of monoammonium phosphate, 10 parts of potassium hydroxide, 28 parts of humic acid, 9 parts of sodium hydroxide, and 3 parts of trace elements.

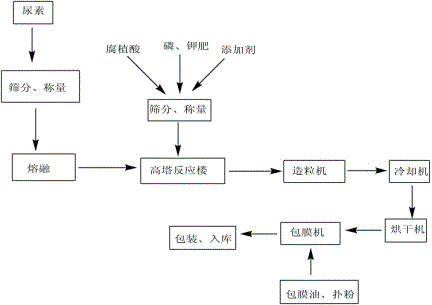

[0020] Such as figure 1 A kind of humic acid synchronous slow-release fertilizer production method that shown a kind of high tower technology production comprises the following steps:

[0021] Step 1: Weigh raw materials, and weigh raw materials in proportion: 39 parts of urea, 11 parts of monoammonium phosphate, 10 parts of potassium hydroxide, 28 parts of humic acid, 9 parts of sodium hydroxide, and 3 parts of trace elements;

[0022] Step 2: 39 parts of the weighed urea enter the urea melter through the feeding port, and the urea is melted and transported to the buffer tank;

[0023] The third step: 10 parts of potassium hydroxide, 11 parts of monoammonium phosphate, and 10 parts of sodium hydroxide are wei...

Embodiment 2

[0031] A humic acid synchronous slow-release fertilizer formula produced by a high-tower process by weight: 38 parts of urea, 10 parts of monoammonium phosphate, 12 parts of potassium hydroxide, 31 parts of humic acid, 7 parts of sodium hydroxide, and 2 parts of trace elements.

[0032] Such as figure 1 The production method of the humic acid synchronous slow-release fertilizer that a kind of high-tower process is shown comprises the following steps:

[0033] Step 1: Weigh the raw materials, and weigh the raw materials according to the proportion: 38 parts of urea, 10 parts of monoammonium phosphate, 12 parts of potassium hydroxide, 31 parts of humic acid, 7 parts of sodium hydroxide, and 2 parts of trace elements;

[0034] The second step: 38 parts of urea after weighing in the urea melter, and transport the urea to the buffer tank after melting;

[0035] The third step: 12 parts of potassium hydroxide, 10 parts of monoammonium phosphate, and 7 parts of sodium hydroxide are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com