Spartina alterniflora straw compost as well as preparation method and application thereof

A technology of Spartina alterniflora and straw, which is applied in the field of Spartina alterniflora straw composting and its preparation, can solve the problems of organic acid accumulation, soil carbon-nitrogen ratio imbalance, environmental problems, etc., and achieve changing pH, improving conversion rate, killing The effect of eliminating pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

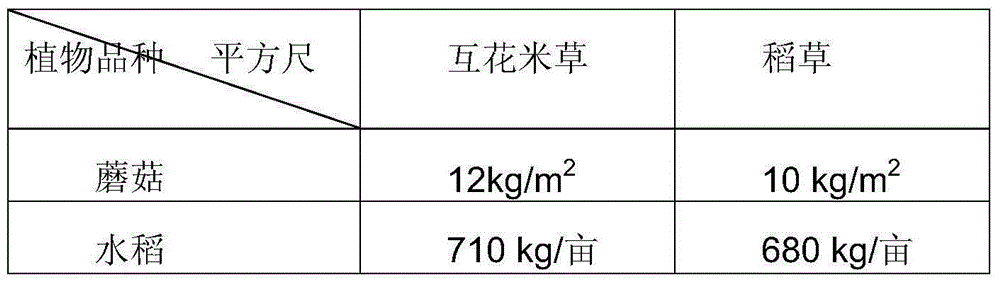

Embodiment 1

[0025] Calculated on the basis of an area of 1,000 square feet of composting site.

[0026] Compost raw materials: 2500 kg of Spartina alterniflora straw, 500 kg of dry cow dung, 75 kg of barley, 25 kg of rapeseed, 70 kg of quicklime, 60 kg of gypsum powder, 60 kg of superphosphate, and 25 kg of urea.

[0027] Preparation:

[0028] Crush the dried cow dung for later use; grind the barley and rapeseed into powder for later use.

[0029] The production method of Spartina alterniflora straw compost:

[0030] First, water the stalks of Spartina alterniflora thoroughly with water. It is advisable to grab the stalks and see the water drop in drops. Let it stand for 1-3 days, and add crushed cow dung, barley flour, rapeseed powder, gypsum powder, Stir superphosphate and urea evenly, stack them into a cuboid shape, and place them for 5 days; add 35 kg of quicklime, stir evenly with an excavator, pile them up into a cuboid shape, and place them for another 5 days; add 35 kg of quic...

Embodiment 2

[0036] Calculated on the basis of an area of 1,000 square feet of composting site.

[0037] Compost Raw Materials:

[0038] 2,500 kg of rice straw, 500 kg of dry cow dung, 75 kg of barley, 25 kg of rapeseed, 70 kg of quicklime, 60 kg of gypsum powder, 60 kg of superphosphate, and 25 kg of urea.

[0039] Preparation:

[0040] Crush the dried cow dung for later use; grind the barley and rapeseed into powder for later use.

[0041] How to make rice straw compost:

[0042] First, water the straw stalks thoroughly with water. It is advisable to pick up the stalks and see water droplets falling. Let it rest for 1-3 days. At the same time, add crushed cow dung, barley flour, rapeseed powder, gypsum powder (for mushrooms), superphosphate 1. Stir the urea evenly, stack it into a rectangular shape, and place it for 5 days; add 35 kg of quicklime, turn it once with an excavator, pile it into a rectangular shape, and put it for another 5 days; add 35 kg of lime and turn it over again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com