Elevator traction machine brake precision control system and method

An elevator traction machine, precision control technology, applied in the direction of the hoisting device, etc., can solve the problems such as the reduction of the effective braking area of the brake shoe, the uneven force on the braking surface, the reduction of the braking force of the brake, etc., and achieves simple structure and low cost. Low, the effect of preventing the drop in braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

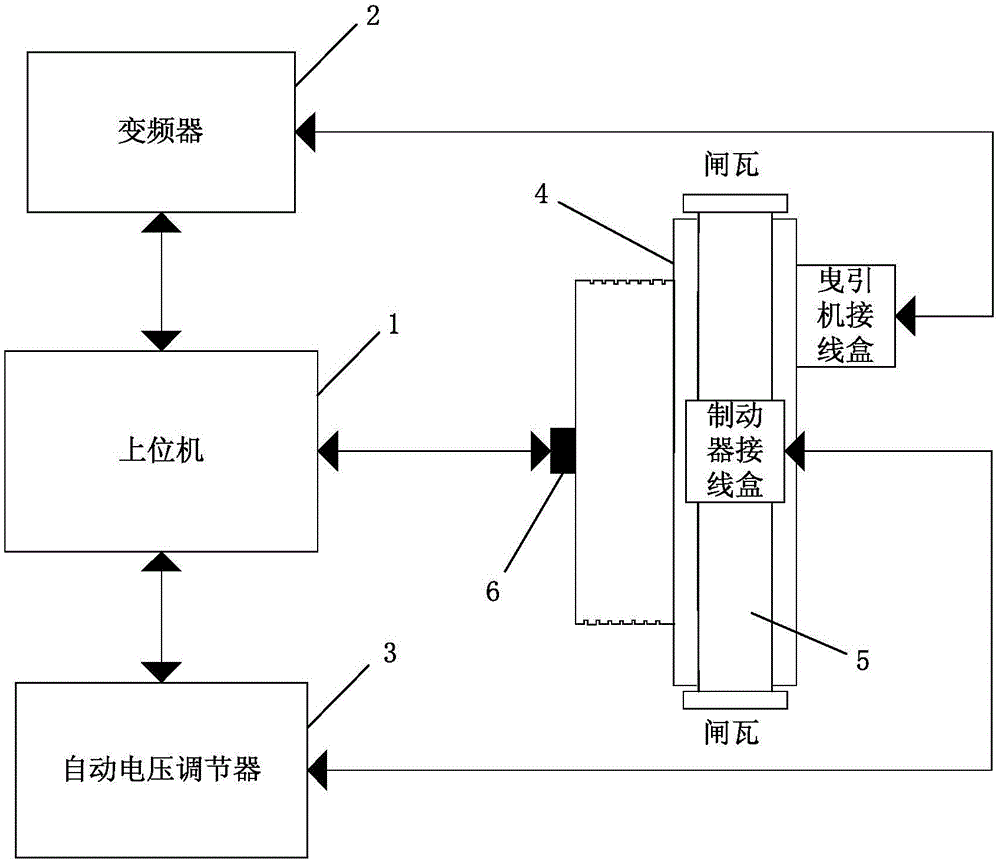

[0039] Such as figure 1 As shown, the system for realizing the precision control of the brake of the elevator traction machine in this embodiment includes a host computer 1, and the host computer 1 is connected with the encoder 6, and is connected with the brake 5 through the automatic voltage regulator 3 (the automatic voltage regulator 3 connected to the junction box of the brake 5), and connected to the traction machine 4 through the frequency converter 2 (the frequency converter 2 is connected to the junction box of the traction machine 4), so as to realize the connection of the frequency converter 2, the automatic voltage regulator 3, Control of the traction machine 4, brake 5 and encoder 6; wherein, the brake is a block brake or a drum brake, the encoder is an incr...

Embodiment 2

[0049] In this embodiment, both the brake and the traction machine are in the state of complete machine installation and commissioning.

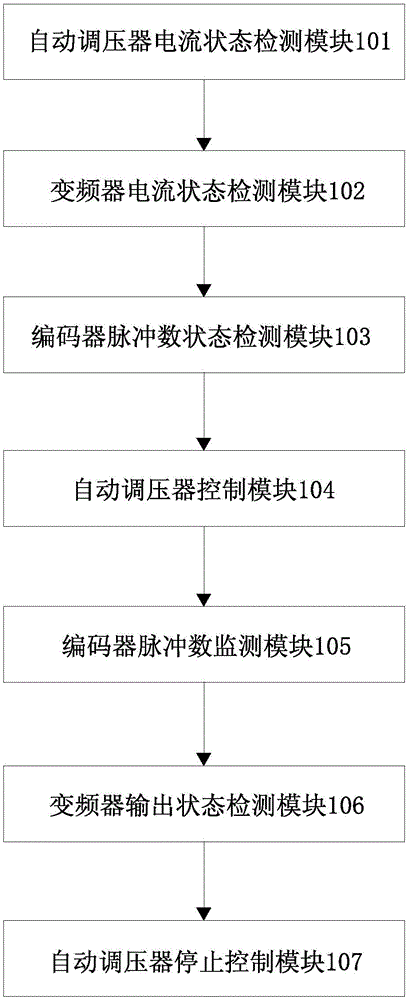

[0050] Such as image 3 As shown, this embodiment provides a method for realizing the precision control of the brake of the elevator traction machine. The method is applied to the host computer and includes the following steps:

[0051] S1. At the initial stage of the system, detect whether the current of the automatic voltage regulator has no output, if so, judge that the brake is in the brake state, and enter step S2, if not, issue a fault prompt, and end the program operation;

[0052] S2. Detect whether the current of the frequency converter has no output. If so, judge that the traction machine is in a non-working state, and proceed to step S3. If not, issue a fault prompt and end this program operation;

[0053] S3. Check whether the number of pulses of the encoder has not changed, if so, enter step S4, if not, issue a fault prompt, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com