A 90-degree arrangement conveying device

A technology of arranging conveying devices and clamping conveying, which is applied in the directions of conveyor objects, transportation and packaging, etc., can solve the problems of increased space occupied by horizontal output, waste of production lines during shutdown and maintenance, and lengthened lines, so as to shorten the length, prevent the The effect of extrusion deformation or even damage and space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

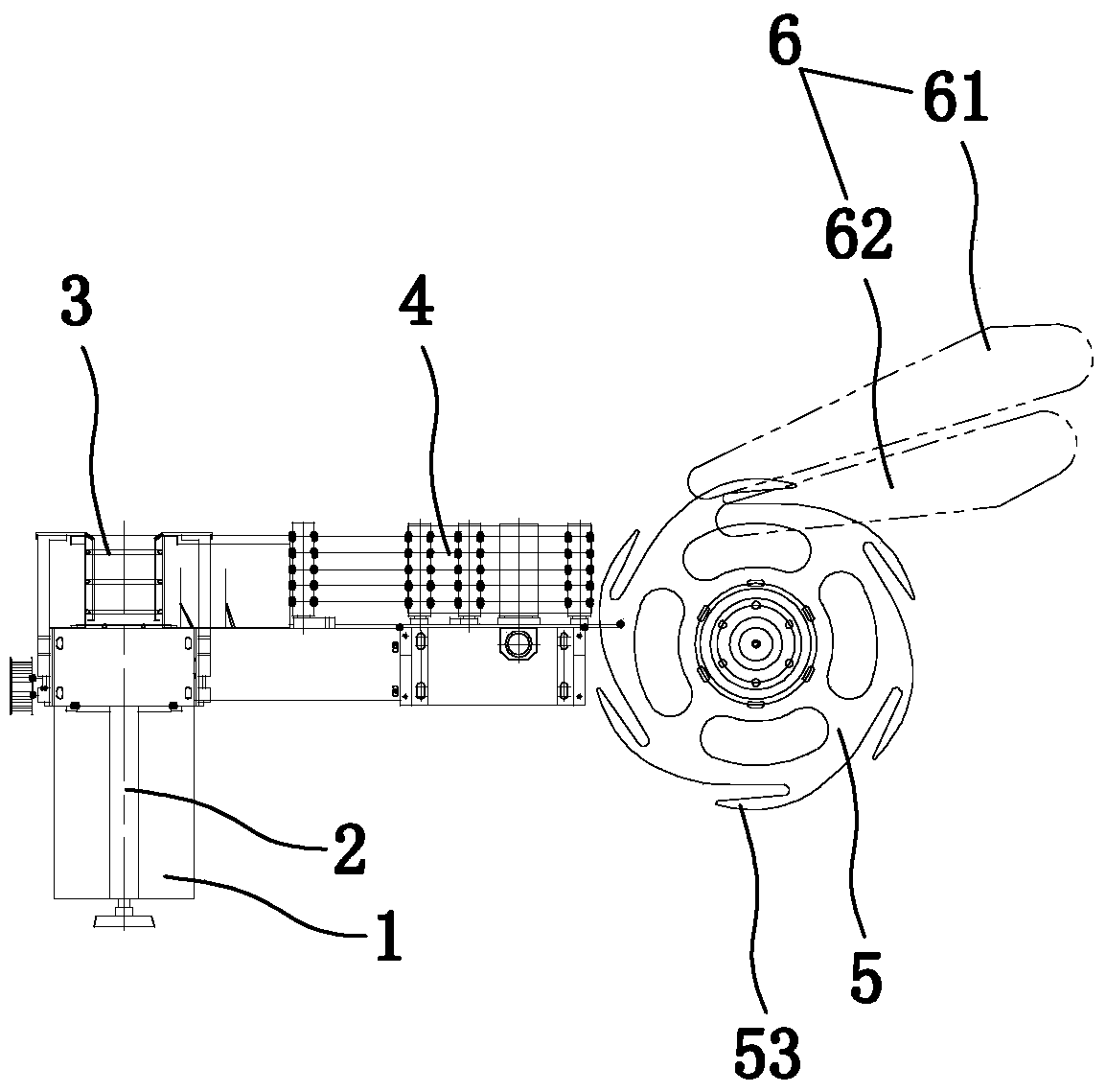

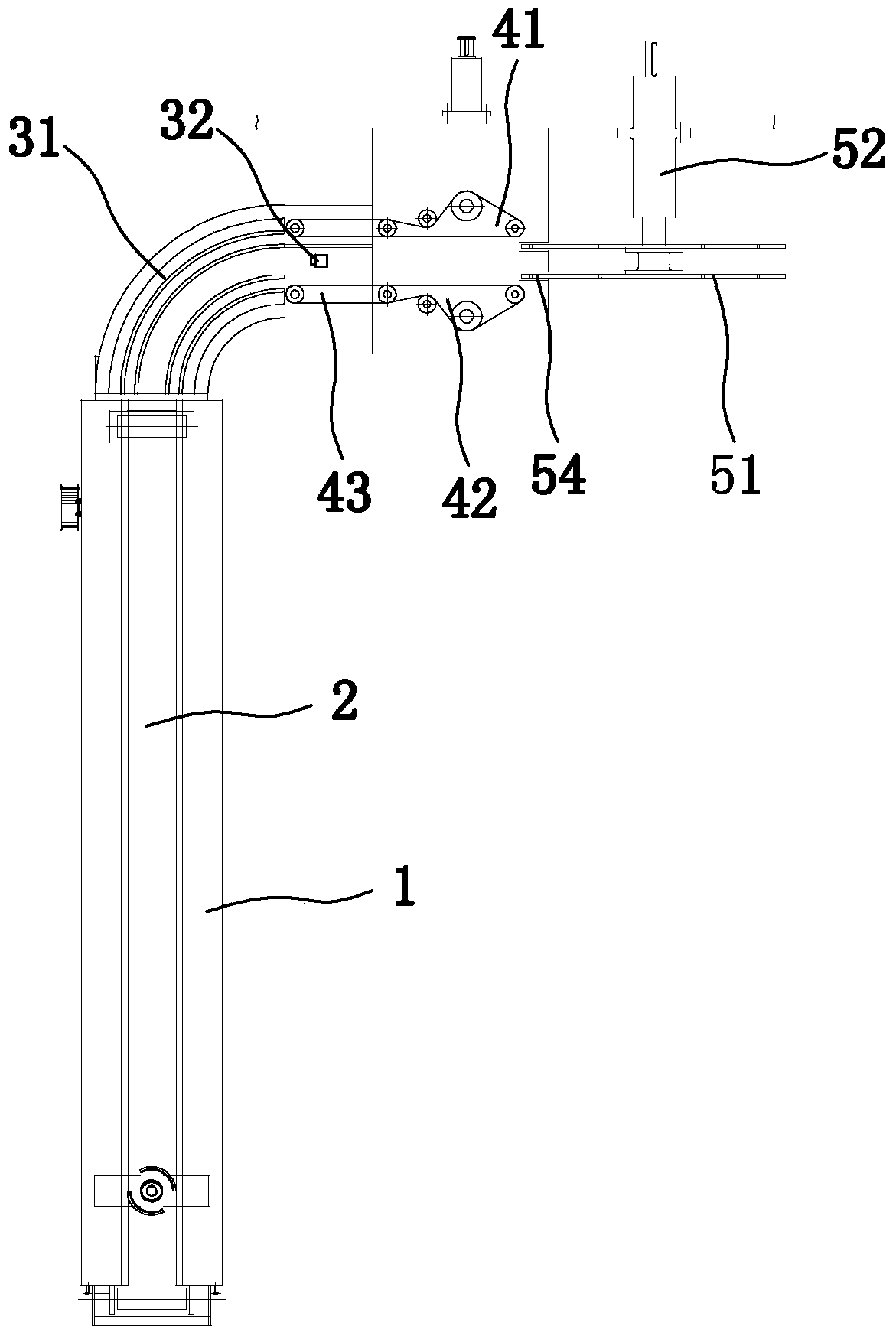

[0011] figure 1 , figure 2 Shown, a kind of 90 degree arranges conveying device, comprises frame 1 and is arranged on frame 1 according to assembly line conveying device 2, 90 degree right-angle turning device 3, clamping conveying device 4, single sheet clamping transfer device 5, The 90-degree right-angle turning device 3 includes two clamping plates 31 clamping left and right to form an arc-shaped guide groove, and a suction head 32 that can be telescopically arranged on the frame 1 up and down. The suction head 32 is located near the clamping On one end of the conveying device 4 and the suction direction is aligned with the output end of the 90-degree right-angle turning device 3, the clamping conveying device 4 includes a rear conveyor belt 41, a front conveyor belt 42, and the rear conveyor belt 41, the front conveyor belt 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com