Blade gap adjusting and locking mechanism for plate shearing machine

A technology of locking mechanism and gap adjustment, which is applied in the direction of knives, shearing devices, metal processing equipment, etc. used in shearing machine devices, and can solve the problems of easy loosening of screws, inaccuracy, and uniformity of gap between upper and lower blades, etc., to achieve Avoid loose, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

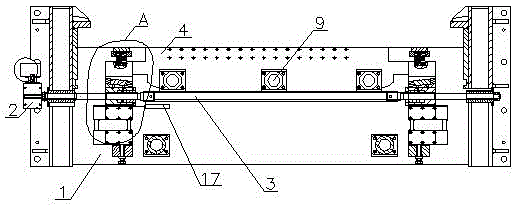

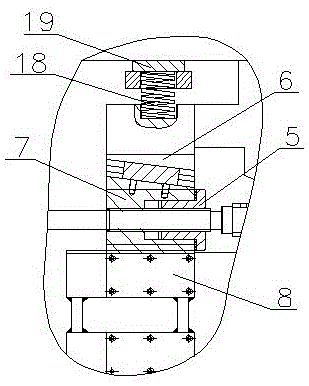

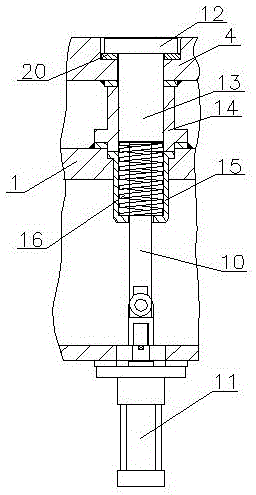

[0017] A blade clearance adjustment and locking mechanism of a shearing machine, comprising a reduction motor 2 installed on one side of a shearing machine frame 1, a screw rod 3 connected to the output end of the reduction motor 2, and a lower motor mounted on the frame 1 Knife holder 4, nuts 5 are sleeved at both ends of the screw rod 3, two fixed slanting blocks 6 are fixedly installed on the lower knife holder 4, and slanting blocks 7 are respectively sleeved on the outside of the two nuts 5. The block 7 is in close contact with the fixed slanting block 6, the horizontal side of the slanting block 7 matches the support block 8 installed on the frame 1, and the lower tool holder 4 is connected with the frame 1 through a locking mechanism 9; The locking mechanism 9 includes a connecting rod 10, the lower end of the connecting rod 10 is connected to the oil cylinder 11 installed on the frame 1, the upper end of the connecting rod 10 is provided with a pressing plate 12, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com