Novel PCD milling tool generating few accumulated chips at tool edge

A technology of chip accumulation and cutting edge, which is applied in the field of new PCD milling cutters, can solve the problems of shortened service life of PCD milling cutters, affecting surface smoothness, and wear of workpieces, so as to facilitate the formation and removal of cutting, improve service life, The effect of reducing the generation of chip accumulation on the edge of the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

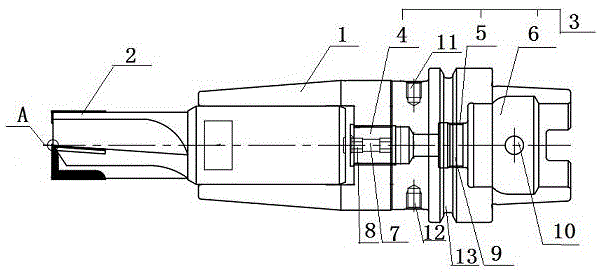

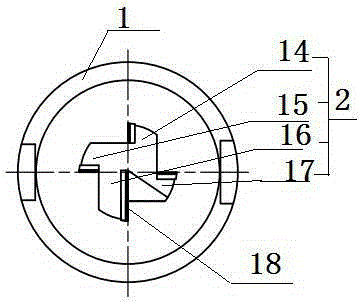

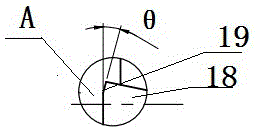

[0014] A new type of PCD milling cutter with less chip accumulation on the cutting edge, comprising a handle 1 and a four-leaf cutter head 2, wherein, the tail end of the handle 1 is provided with a mounting groove 3 towards the inside of the handle, and the mounting groove 3 is formed by a shaft End connecting groove 4, sealing groove 5 and locking positioning groove 6, the two ends of the sealing groove 5 are respectively connected with the shaft end connecting groove 4 and locking positioning groove 6, the locking positioning groove 6 is located at the end of the handle The shaft end connecting groove 4 is provided with a shaft pin 7, and the surface of the shaft pin 7 is provided with a plurality of protrusions 8, and the plurality of protrusions 8 are arranged around the shaft pin 7, and the inner wall of the sealing groove 5 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com