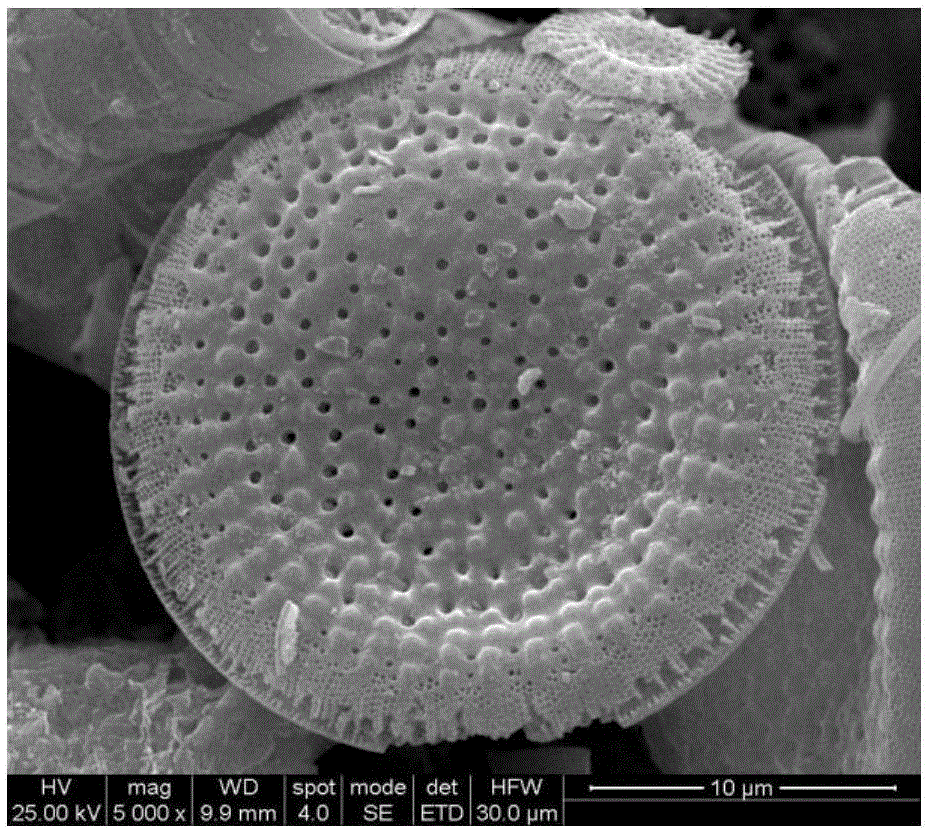

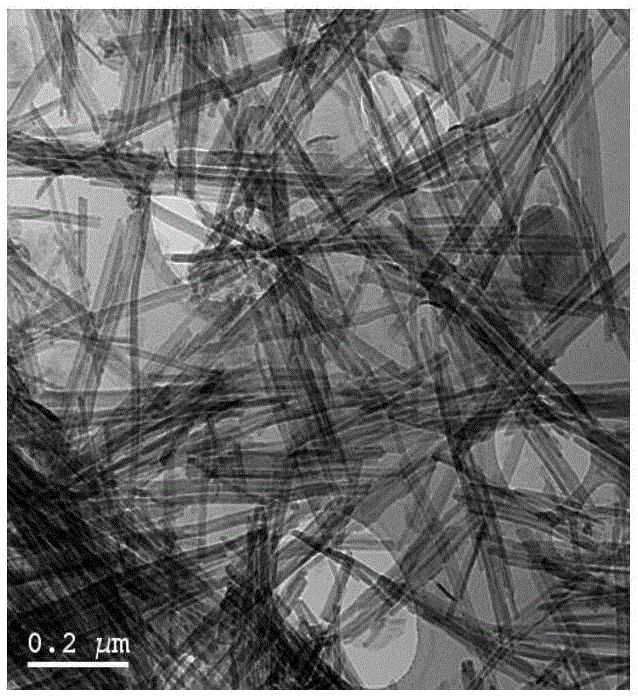

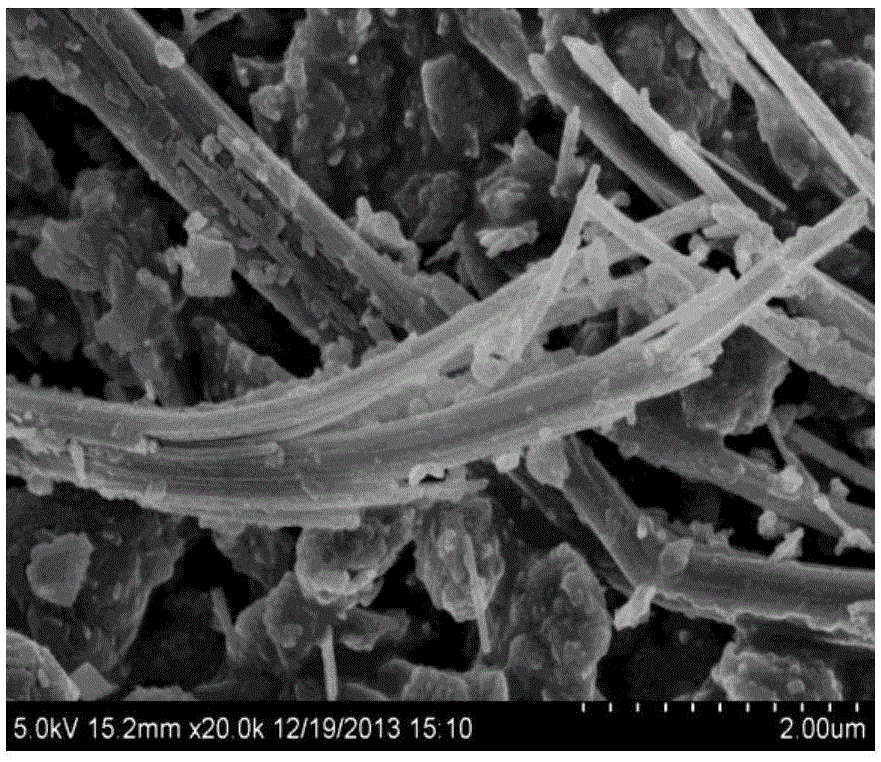

Modified compound kieselguhr adsorbing agent for treating industrial wastewater and preparation method

A technology for industrial wastewater and adsorbents, applied in chemical instruments and methods, adsorbed water/sewage treatment, alkali metal compounds, etc., can solve problems such as poor performance and limited treatment effect of a single diatomite adsorbent, and achieve strong adsorption capacity , good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 500g of diatom concentrate obtained from Beifeng Diatomite Co., Ltd., Linjiang City, Jilin Province after beneficiation, was calcined in a laboratory rotary tube furnace at 450°C for 1.5h; Stir evenly in a three-neck flask in the laboratory and heat it in a water bath. After the temperature of the slurry rises to 75°C, add 2.0g of hexadecyltrimethylammonium bromide, heat-preserve and modify at 70-80°C for 1.5h, then filter, Washing, and drying the washed filter cake in a drying oven at 105°C to obtain modified diatomite.

[0026] Take 65 g of the above-mentioned modified diatomite, 30 g of attapulgite, and 5 g of magnesium-silicon slag extracted from serpentine and mix them uniformly in a laboratory stirrer to obtain a modified composite diatomite adsorbent.

[0027] Take DESMP (diethyl p-toluenesulfonyloxymethyl phosphate) production wastewater 1000mL. The wastewater has complex components, high organic content and a certain amount of inorganic salt, and the chemical ...

Embodiment 2

[0030] Take 70 g of modified diatomite prepared in Example 1, 5 g of attapulgite, and 25 g of serpentine-extracted magnesium-silicon slag and mix them uniformly in a laboratory mixer to obtain a modified composite diatomite adsorbent.

[0031] Take 1000mL of wastewater discharged from an oilfield in the north, the COD of the wastewater is 1.92mg / L, and the pH value is 6-7.

[0032] Add 7g of modified composite diatomaceous earth adsorbent to the above 1000mL wastewater, and stir at 30°C for 1.5h. The COD of the treated water sample is 36.85mg / L, and the COD removal rate is 84.77%.

Embodiment 3

[0034] 500g of diatom concentrate obtained from Beifeng Diatomite Co., Ltd., Linjiang City, Jilin Province after beneficiation, was calcined in a laboratory rotary tube furnace at 450°C for 1.5h; Stir evenly in a three-neck flask in the laboratory and heat it in a water bath. After the pulp temperature rises to 75°C, add 4.0g of hexadecyltrimethylammonium bromide, heat-preserve and modify at 70-80°C for 1.5h, then filter, Washing, and drying the washed filter cake in a drying oven at 105°C to obtain modified diatomite.

[0035] Take 60 g of the above-mentioned modified diatomite, 33 g of attapulgite, and 7 g of magnesium-silicon slag extracted from serpentine and mix them uniformly in a laboratory mixer to obtain a modified composite diatomite adsorbent.

[0036] Get 1000 mL of DESMP (diethyl p-toluenesulfonyloxymethyl phosphate) production wastewater whose components, COD and pH are the same as in Example 1.

[0037]Add 200 g of modified composite diatomite adsorbent to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com