Reverse-rotation soil-clamping type dry land bowl-taking transplanting mechanism with Lagrange planetary gear train

The technology of a planetary gear train and a planetary gear carrier is applied in the field of transplanting mechanism, which can solve the problems of poor seedling breakage rate of seedling fibrosis, influence of popularization and application, damage to seedlings, etc., and achieves good operation quality, low seedling damage rate and novel structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

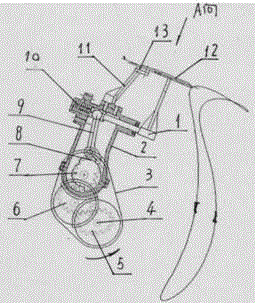

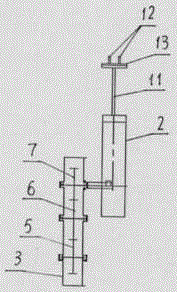

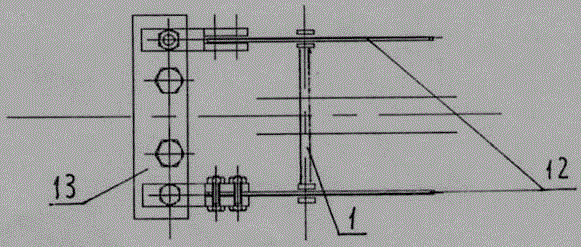

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A Lagrangian planetary gear train reversing soil-clamping dry field transplanting mechanism, a Lagrangian non-circular sun gear 5 is fixed on the frame 4, and the planetary gear frame 3 is rotatably installed on the frame 4 Above, the Lagrangian noncircular intermediate gear 6 and the Lagrangian noncircular planetary gear 7 are rotatably fitted on the planet carrier 3, and the Lagrangian noncircular intermediate gear 6 and the Lagrange The non-circular sun gear 5 meshes with the Lagrange non-circular planetary gear 7 to form a non-uniform Lagrangian non-circular gear planetary gear train. The Lagrange non-circular planetary gear 7 and the Lagrange non-circular planetary gear The circular sun gear 5 is the same; on the Lagrangian non-circular planetary gear 7, the transplanting arm housing 2 is fixed at the outer part of the planetary wheel carrier 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com