Permanent magnet synchronous motor rotor and permanent magnet synchronous motor

A permanent magnet synchronous motor and rotor technology, which is applied in the direction of synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve high cogging torque, performance degradation of permanent magnet synchronous motor, air The problem of high harmonic content of load back EMF can be achieved to improve performance, optimize the waveform of air gap magnetic field, and reduce the effect of harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

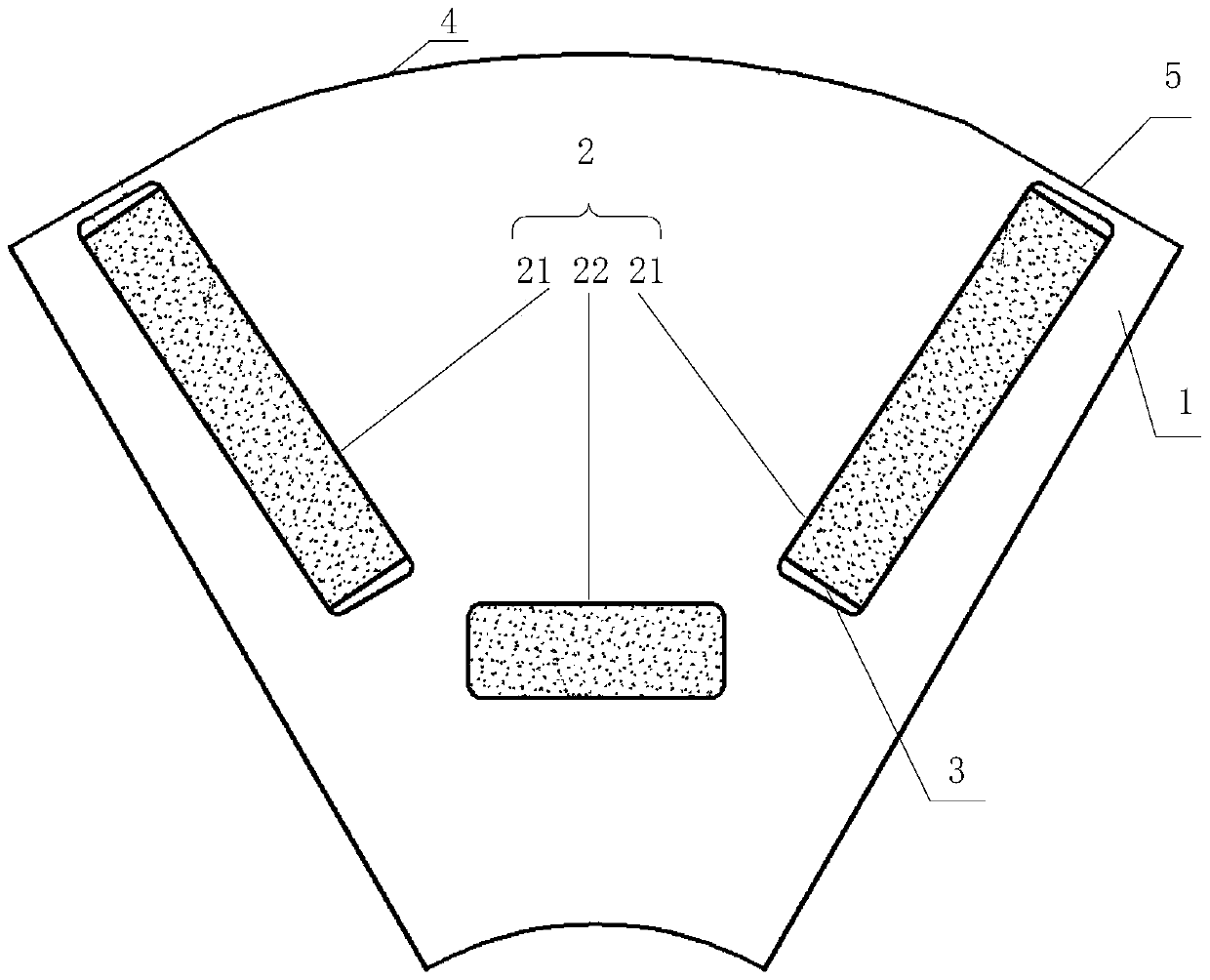

[0023] figure 1 It is a partial structural schematic diagram of the permanent magnet synchronous motor rotor according to Embodiment 1 of the present invention, as figure 1 As shown, the permanent magnet synchronous motor rotor includes: a rotor core 1 and a magnetic circuit assembly 2, wherein the magnetic circuit assembly 2 includes two tangential permanent magnets 21 distributed in the radial direction, and the tangential permanent magnets 21 are arranged in the permanent magnet slots 3, the same polarity of the two tangential permanent magnets 21 is opposite, a radial permanent magnet 22 is arranged between the two tangential permanent magnets 21 and near the inner side of the rotor core 1, and the radial permanent magnet 22 faces One side of the stator has the same polarity as the opposite side of the two tangential permanent magnets 21, and the radial cross-sectional shape of the rotor core 1 is composed of arcs 4 and straight lines 5, wherein the part close to the tange...

Embodiment 2

[0028] This embodiment is a supplementary description based on the first embodiment.

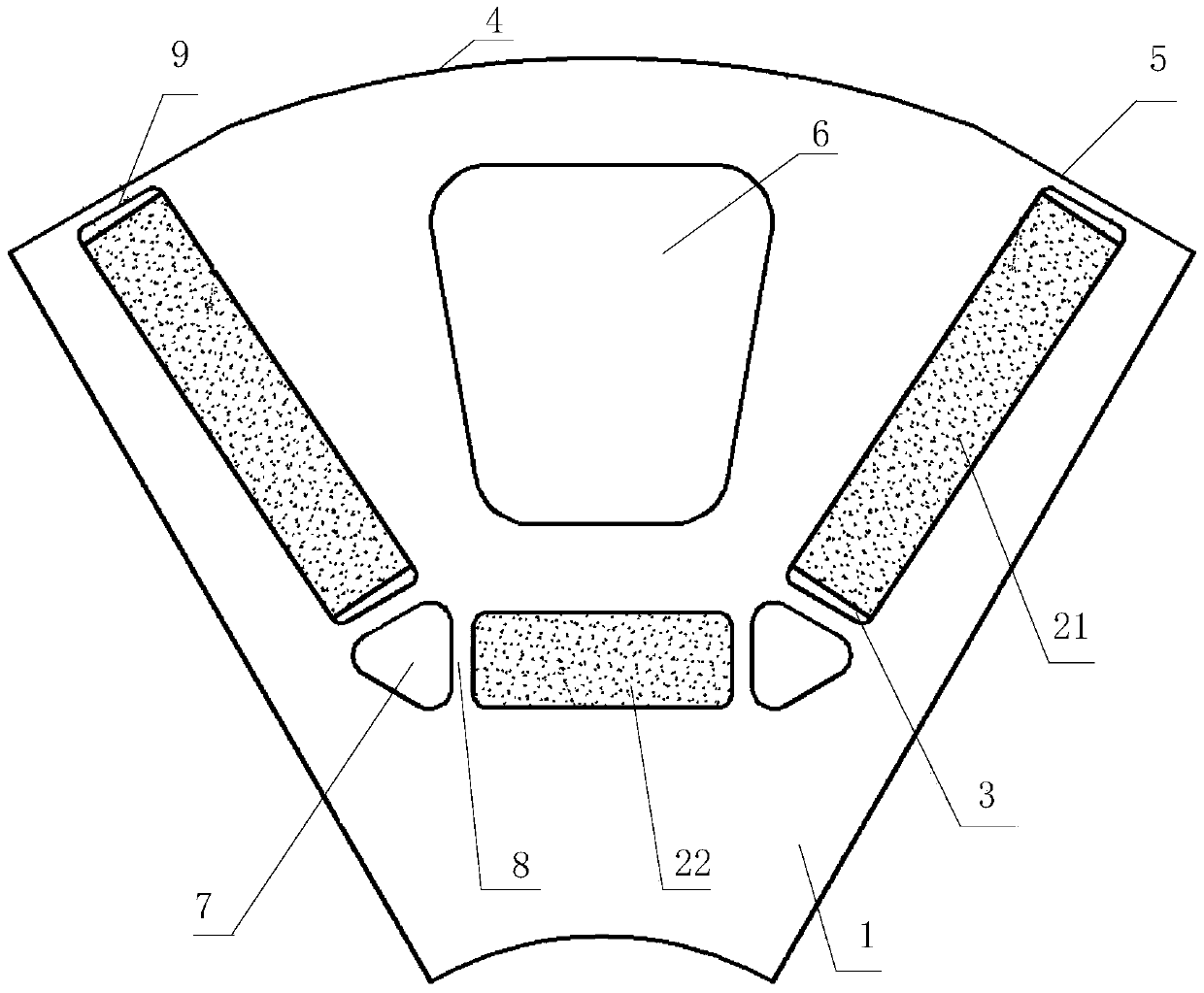

[0029] figure 2 It is a partial structural schematic diagram of the permanent magnet synchronous motor rotor according to Embodiment 2 of the present invention, as figure 2 As shown, the rotor of the permanent magnet synchronous motor also includes an auxiliary hole 6 , and the auxiliary hole 6 is arranged between two tangential permanent magnets 21 .

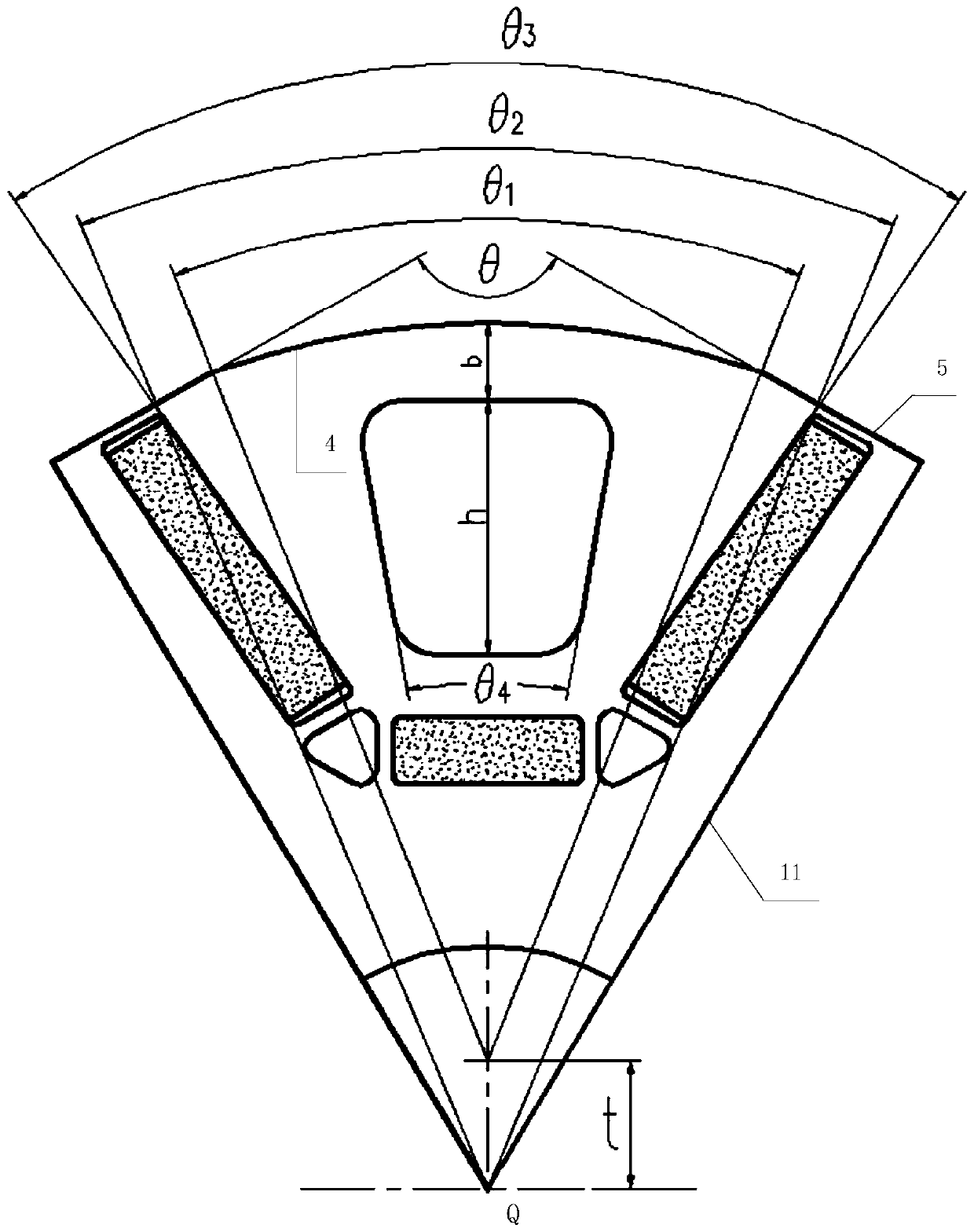

[0030] Further, the auxiliary hole 6 is trapezoidal. image 3 It is a schematic diagram of the positional relationship between the components of the permanent magnet synchronous motor rotor according to Embodiment 2 of the present invention, as image 3 As shown, by adjusting the height h of the trapezoid and the angle θ between the two waists 4 and the minimum distance b from the trapezoid to the surface of the rotor core 1 can optimize and adjust the air gap magnetic field waveform of the permanent magnet synchronous motor rotor, makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com