Housing assembly and connector

A technology of housing assembly and connector, applied in the direction of connection, parts of connection device, electrical components, etc., can solve the problems of connection failure, canted coil spring can not play the role of locking, anti-loosening, disengagement, etc., to ensure reliability and security, the effect of simplifying the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

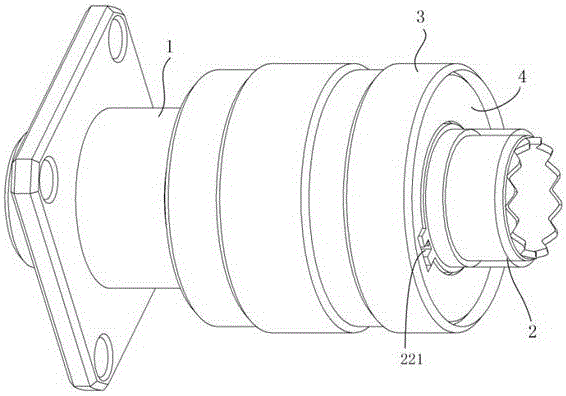

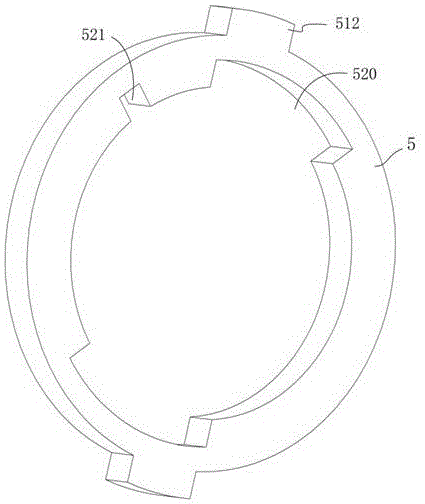

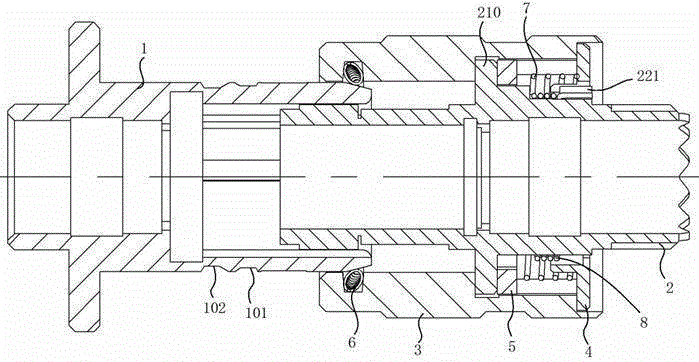

[0032] Embodiment 1 of the connector of the present invention: includes a housing assembly, defines the front end of the housing assembly as a plug-in end 10 for plugging and mating with the adapter connector 1, and the housing assembly includes a canted coil spring at the front end The locking cap 3 is provided with a canted coil spring installation groove 36 on the inner peripheral surface of the front end of the locking cap 3 , and the canted coil spring 6 is installed in the canted coil spring installation groove 36 .

[0033] The housing assembly also includes a connector housing 2 that extends forward and backward. The locking cap 3 is rotatably sleeved on the outer periphery of the connector housing 2, defining the front end of the connector housing 2 as a plug-in end, and the connector housing is plugged in There is an annular space for axially inserting the plug-in end of the adapter connector 1 between the end and the lock cap 3 . The front end of the adapter connect...

Embodiment 3

[0050] Embodiment 3 of the connector of the present invention: the difference from Embodiment 1 is that there is no inner retaining ring between the connector housing and the locking cap, and the torsion spring acts on the connector housing and the locking cap , the two ends of the return spring press against the limit retaining ring and the convex ring of the connector housing respectively. At this time, because there is no retaining ring chute of the inner ring retaining ring, the rotation limit of the locking cap relative to the connector housing is limited. , it cannot be accurately judged at what position the bump on the connector housing is opposite to the straight groove of the lock cap in the circumferential direction, then it is necessary to artificially judge the bump on the connector housing when the lock cap is unlocked The position when it is opposite to the straight groove of the locking cap in the circumferential direction.

[0051] The embodiment of the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com