Fiber Optic Connector Assemblies

A fiber optic connector and component technology, which is applied in the field of fiber optic connector components, can solve the problems of high sensitivity of optical signals to dust and dirt, unfavorable optical signal transmission, and easy entry of dust, so as to reduce production difficulty, reduce transmission impact, reduce The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

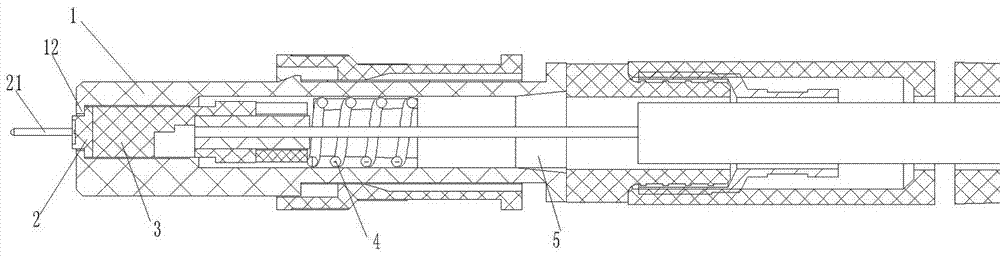

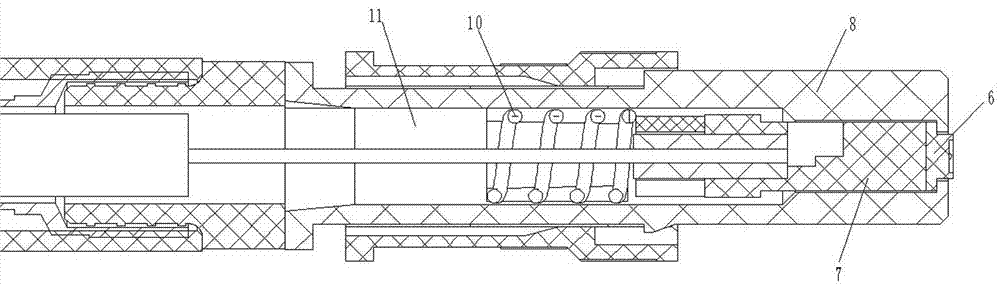

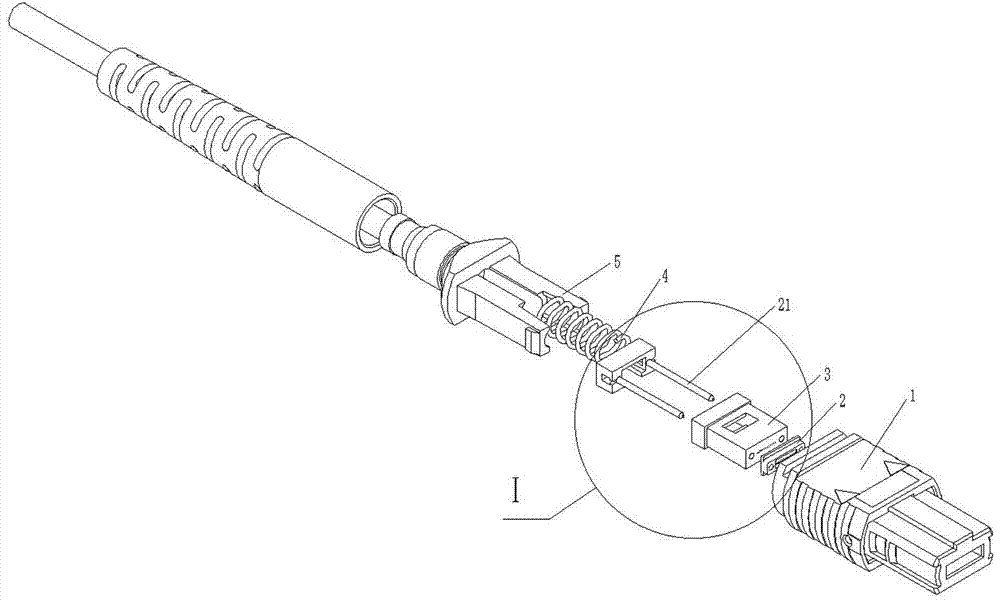

[0024] Examples of fiber optic connector assemblies are Figure 1~8 As shown: it includes the male fiber optic connector and the female fiber optic connector. The rear end of the body is provided with a male rear sleeve 5, and the male optical fiber core is equipped with a male optical fiber core guided and moved along the front and rear directions in the male housing. The rear side of the male optical fiber core is provided with a Active male spring 4. The male fiber optic ferrule includes a male lens seat 2 and a male ferrule mounting seat 3 which are separately arranged at the front and rear. The male optical core channel 18 is arranged on the male ferrule mounting seat, and the male optical core channels form an array multi-core The optical channel, the male optical core channel 18 and the male ferrule mounting seat 3 constitute the MT ferrule, and the male lens seat 2 is provided with a male lens 19 respectively located at the front side of the corresponding male optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com