Method for modified asphalt separation evaluation based on modification agent mixing amount potentiometric titration quantitative analysis

A technology of modified asphalt and potentiometric titration, which is applied in the direction of material electrochemical variables, etc., can solve the problems of low correlation coefficient and low detection accuracy, and achieve the effect of accurate evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

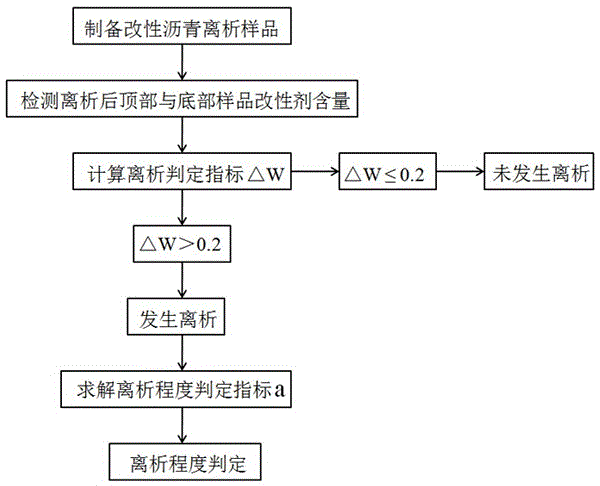

Method used

Image

Examples

Embodiment 1

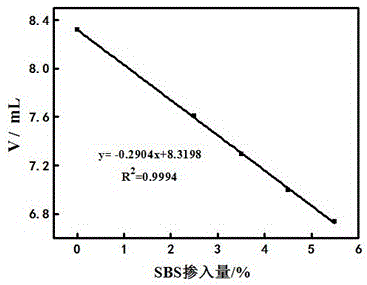

[0084] Three sets of modified asphalt samples A, B, and C with 4.5% SBS content were provided by a well-known company. Samples A and B have the same formula but different processes. They correspond to standard curve 1, and sample C corresponds to standard curve 2. In order to further verify the feasibility of the present invention, carry out 6,24,48,72,120h heat storage test respectively to sample, concrete test procedure is as follows:

[0085] (1) Thermal storage test of SBS modified asphalt samples A, B, and C

[0086] 1. Heat the SBS modified asphalt sample to be tested, stir and inject 50g of the asphalt sample into the standard separation tube;

[0087] 2. Seal the separation tube, then put it in an oven at 163±5°C, and let it stand for 6, 24, 48, 72, 120 hours;

[0088] 3. After heating, take out the separation tube containing the bitumen sample, keep the separation tube upright and place it in the refrigerator to cool until the bitumen is completely solidified;

[00...

Embodiment 2

[0116] In step 2 ii), add 10 mL of Webster's reagent with a concentration of 0.01M to the solution, and react at 30°C for 24 hours; Sodium thiosulfate solution titrates the solution after the above-mentioned ii) step treatment; other processes are the same as in Example 1.

Embodiment 3

[0118] In step two ii), add 30 mL of Webster's reagent with a concentration of 1M to the solution, and react at 50° C. for 8 hours; then add 30 mL of potassium iodide solution with a concentration of 1000 g / L respectively, and react for 60 minutes; iii) use sulfur with a concentration of 2M Sodium sulfite solution titrates the solution after the above-mentioned ii) step treatment; other processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com