Combustibility evaluation method of metal powder and solvent mixture thereof

A solvent mixture and metal powder technology, which is applied in the evaluation field of dangerous and flammable products, can solve the problems such as no clear method for flammability determination and inability to test relevant parameters for state identification, and achieve the effect of eliminating hidden dangers of accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention discloses a method for evaluating the flammability of metal powder and its organic solvent mixture. In order to make the advantages and technical solutions of the invention clearer and clearer, the invention will be described in detail below in conjunction with specific examples.

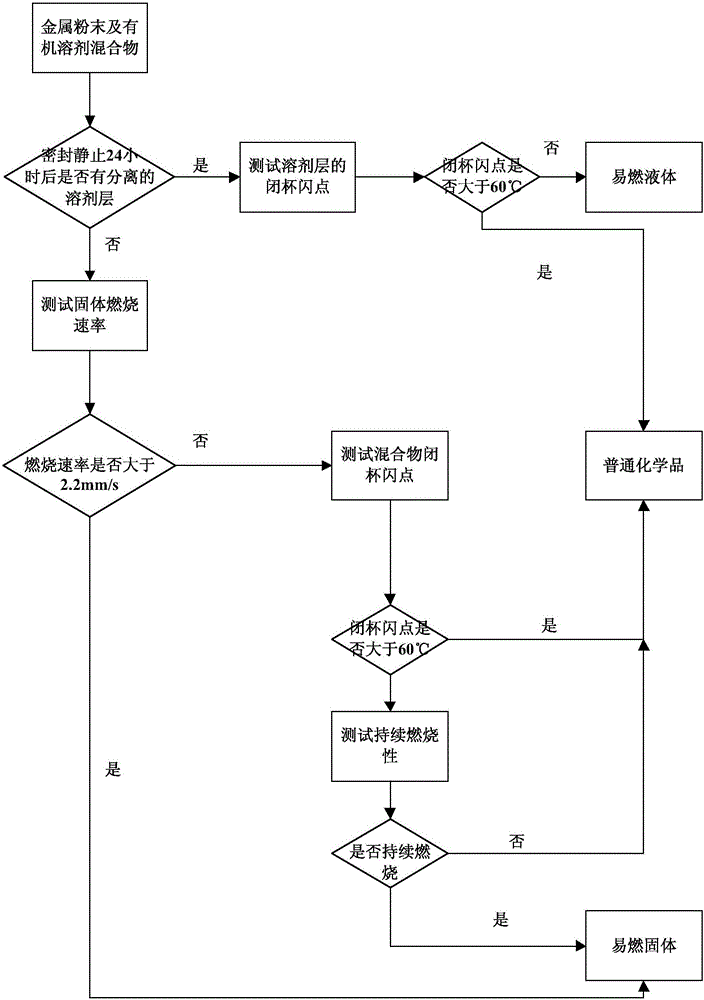

[0018] combine figure 1 Shown, the flammability evaluation method of metal powder and its organic solvent mixture of the present invention specifically comprises the following steps:

[0019] (1) First determine whether the mixture has a flowing organic solvent. If there is a flowing organic solvent, test its closed-cup flash point. If the flash point is less than 60°C, it is a flammable liquid; if there is no flowing organic solvent, the steps ( 2) the test;

[0020] (2) Test according to the test method for solid flammability in the "Manual of Tests and Criteria". If the burning rate is greater than 2.2 mm / s, it is regarded as a flammable solid. If the burning rate is less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com