Detection device for the dissolution time of solid powdery substances in solution

A detection device, a technology of dissolution time, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as the influence of dissolution rate, and achieve the effect of non-destructive online monitoring and broad application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

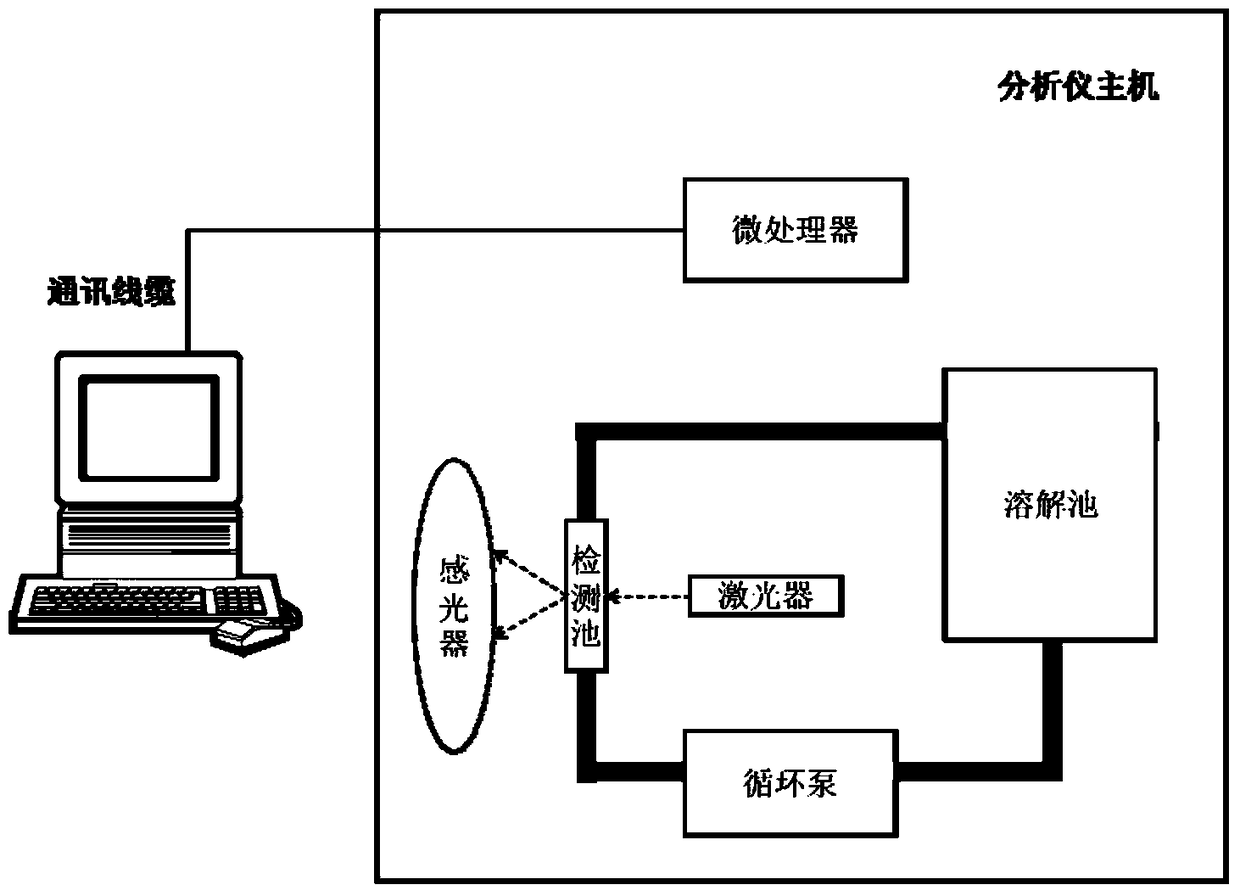

[0041] In this embodiment, a detection device for the dissolving time of a solid powdery substance in a solution has a structure such as figure 1 As shown, the detection device includes a dissolving pool, a circulation pump and an optical detection pool that are sequentially connected to form a loop through pipelines, and an optical emitter (laser) and an optical receiver (photoreceptor) that are respectively arranged on both sides of the optical detection pool. ), the laser light emitted by the optical transmitter is received by the optical receiver after passing through the optical detection cell. At the same time, the detection device is also equipped with a microprocessor (onboard microprocessor) to communicate with each component and then control the action of each component. Control the work of components, collect and process data, and output results.

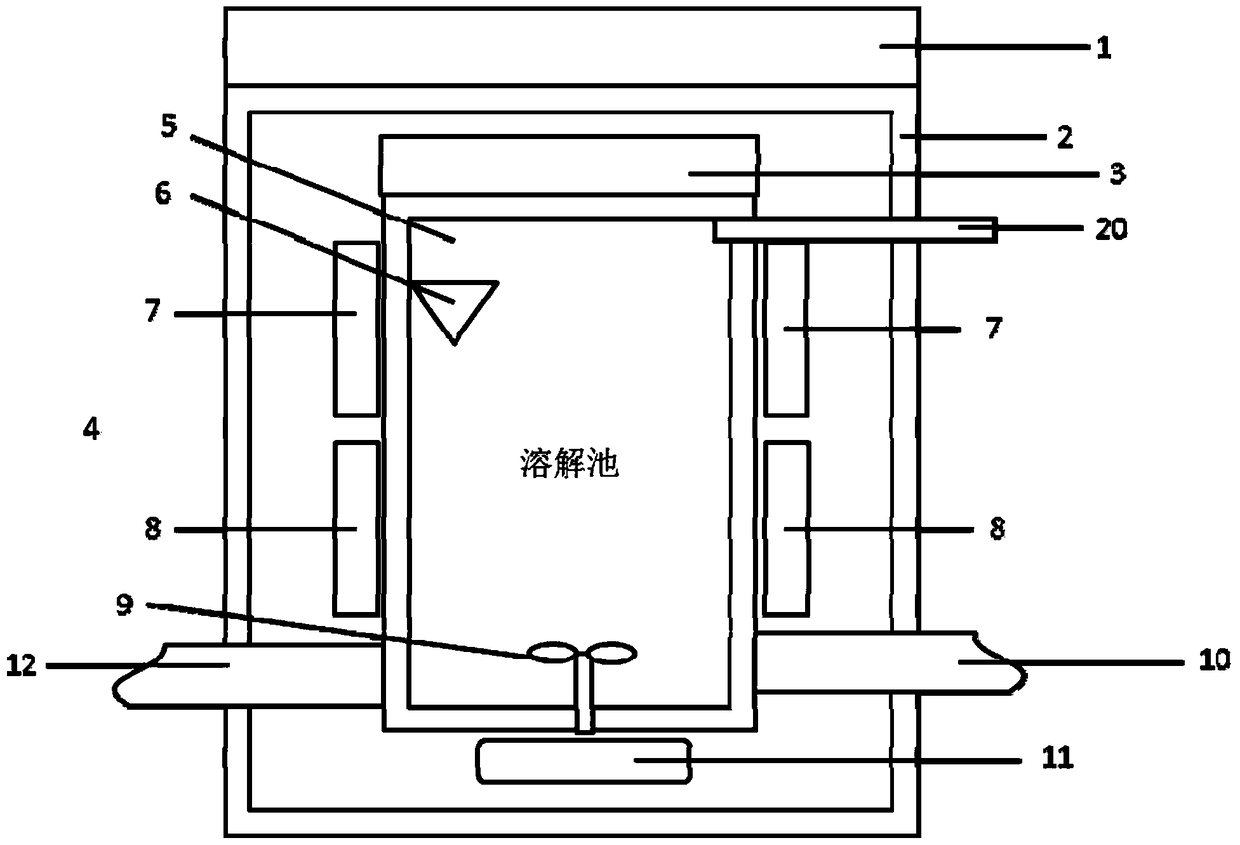

[0042] Wherein, the structure of the dissolution pool is as figure 2 Shown:

[0043] The dissolution pool is divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com